Steel Grating

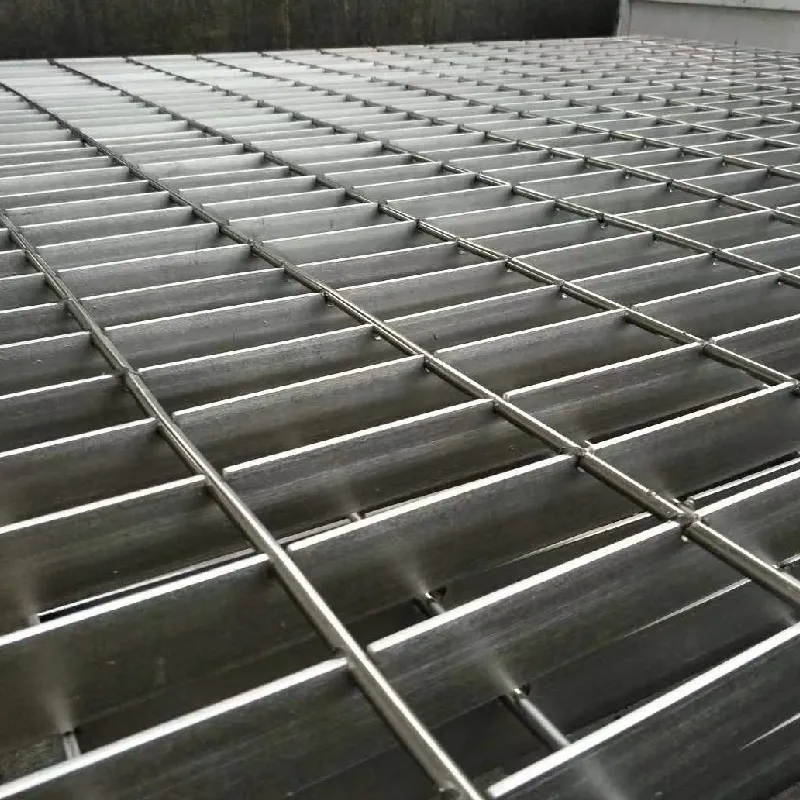

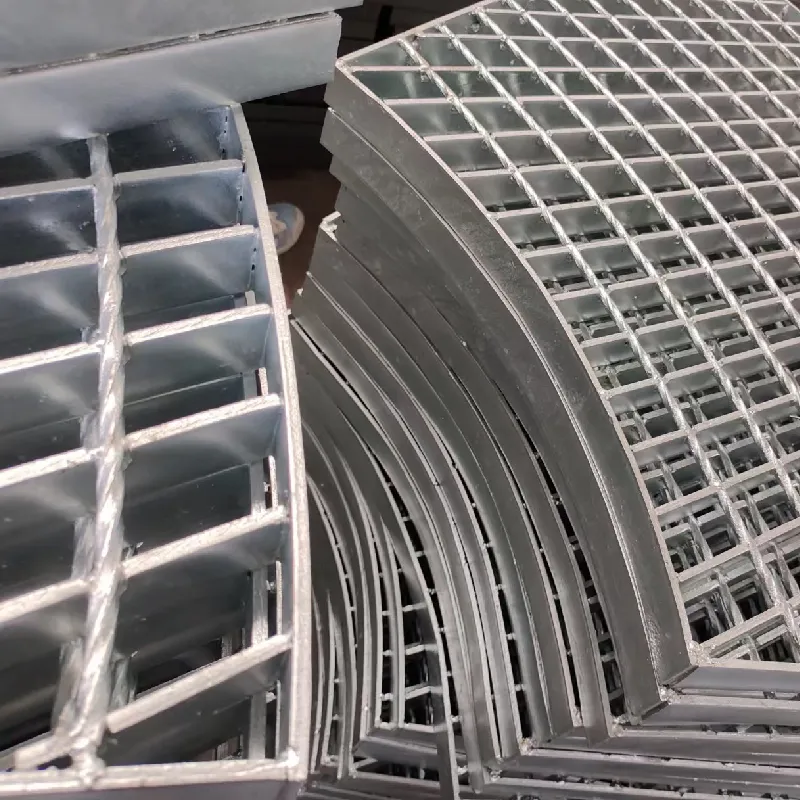

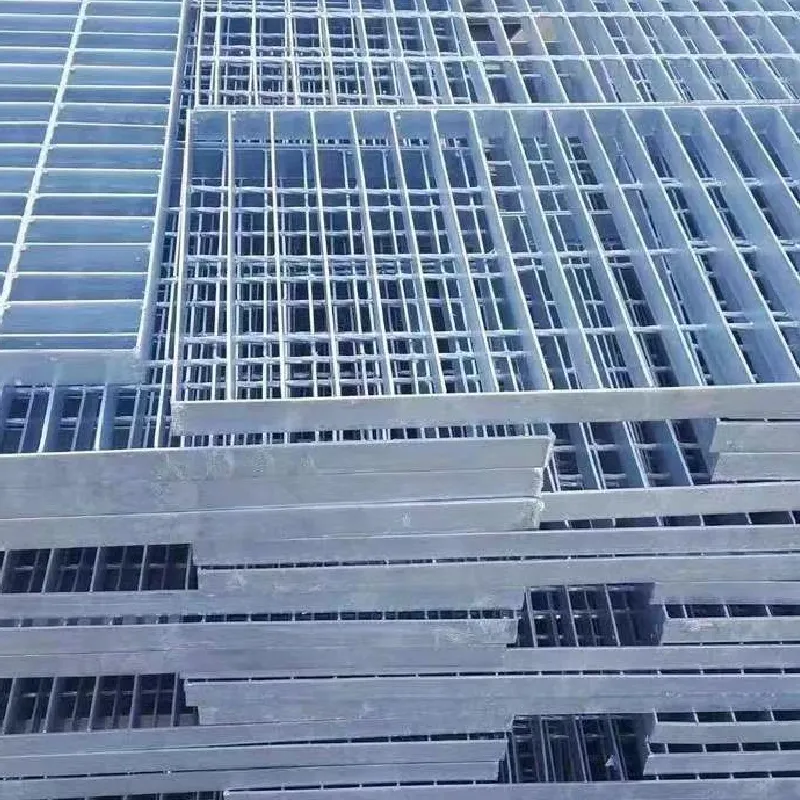

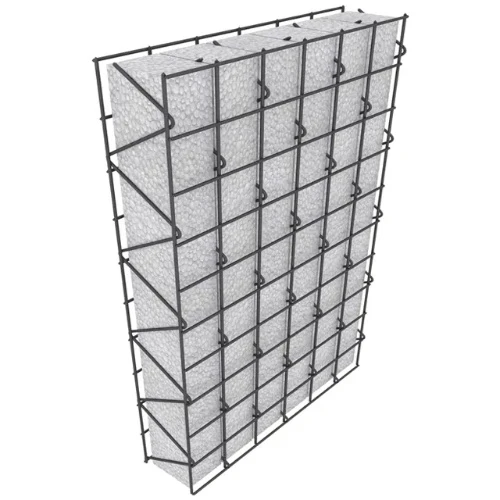

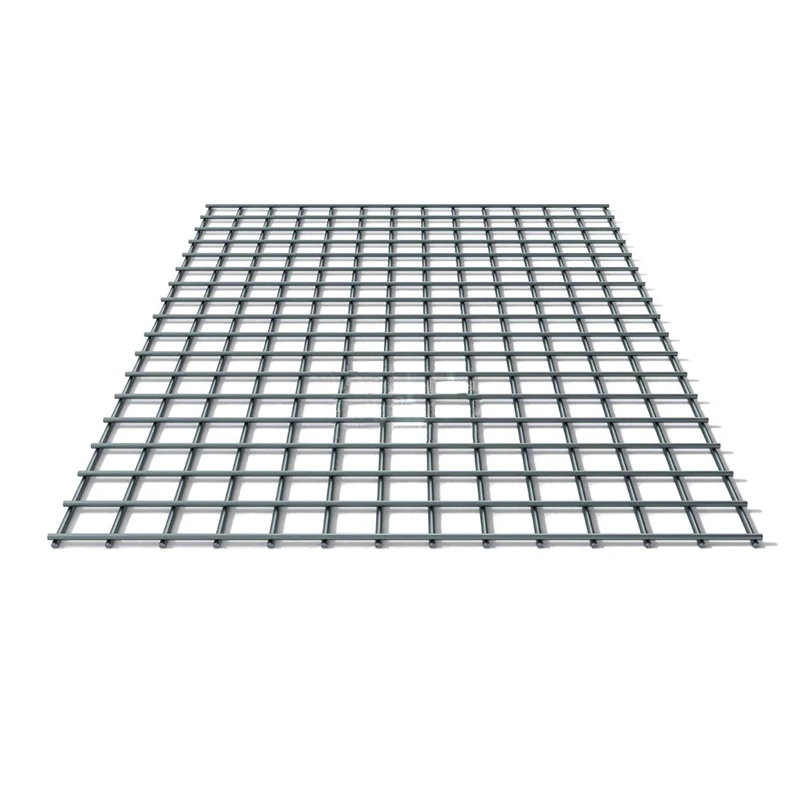

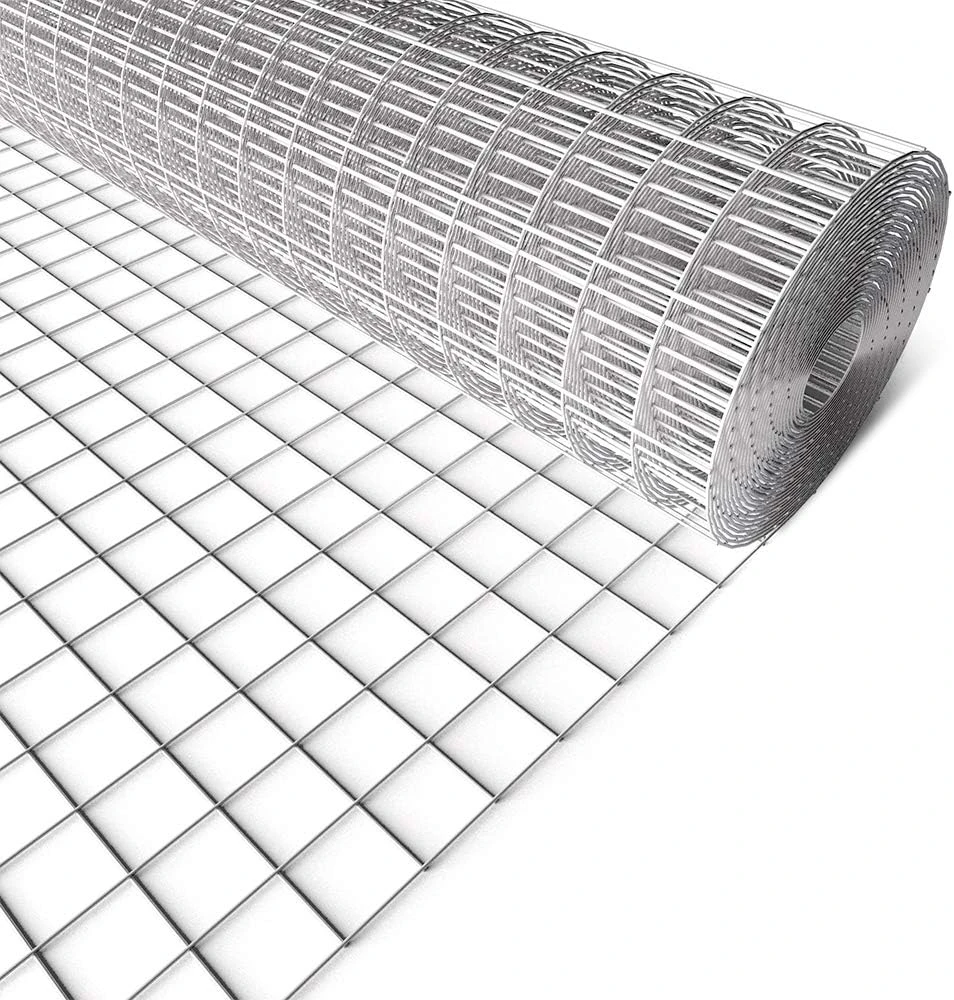

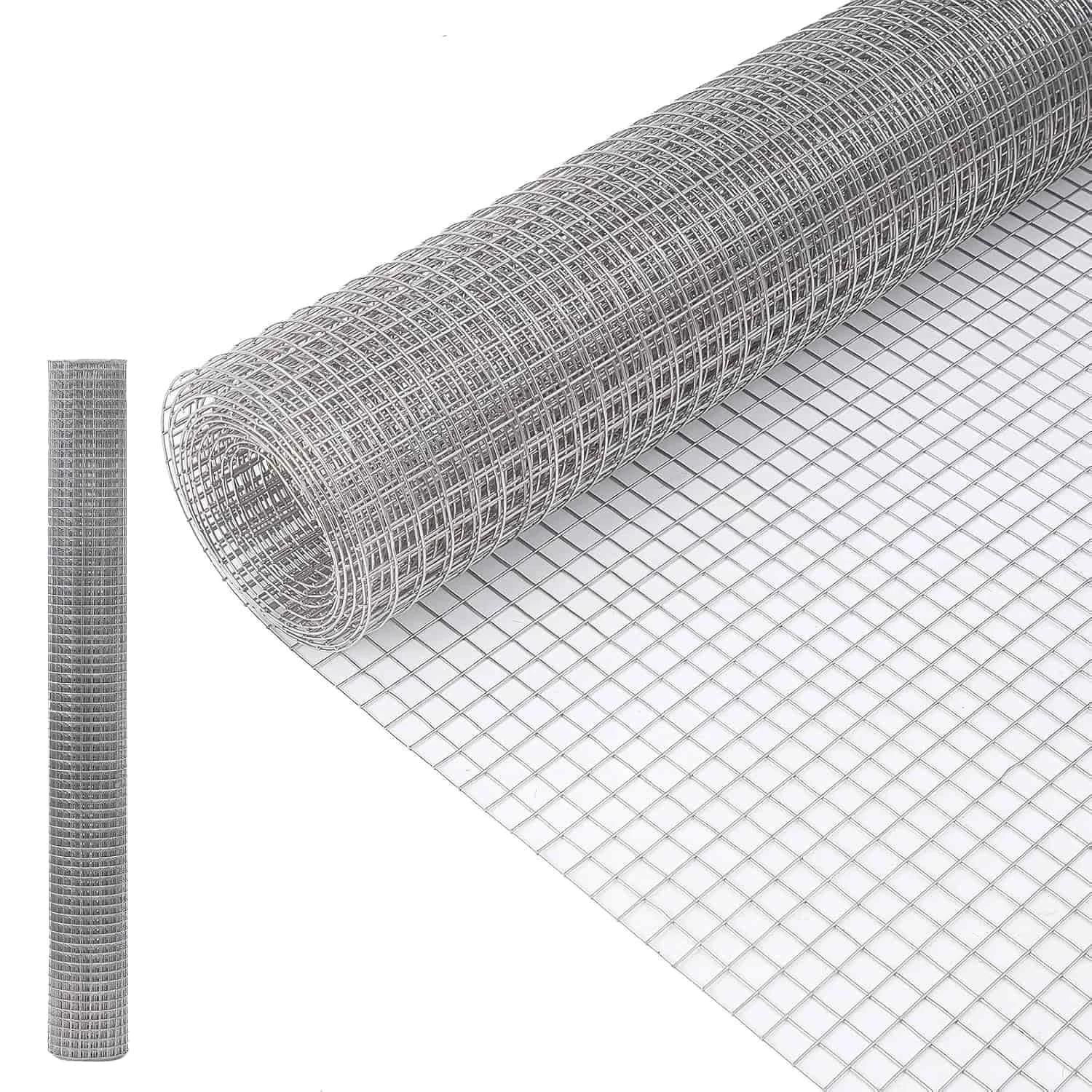

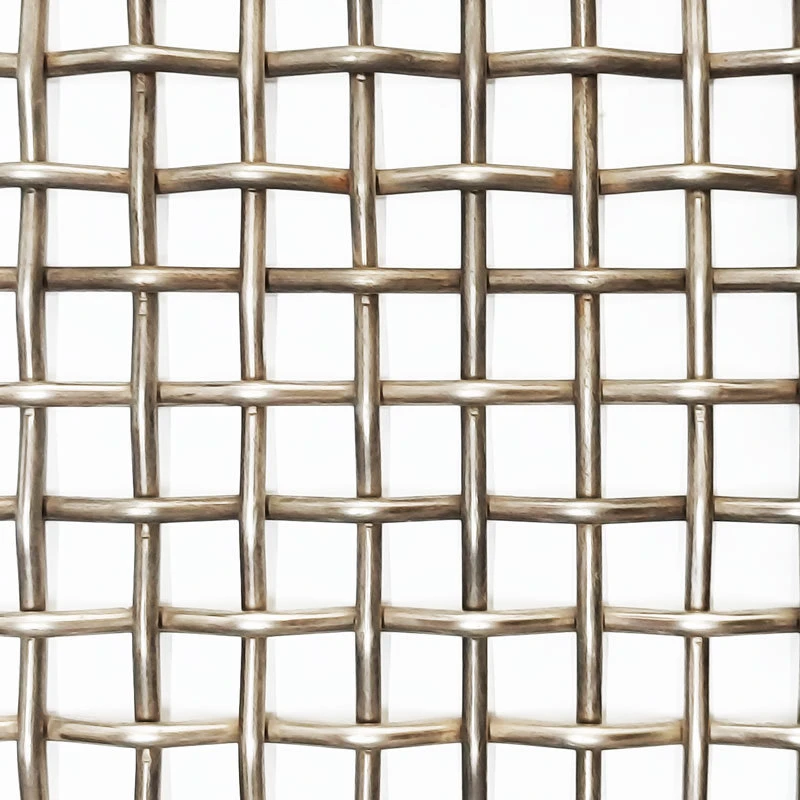

Steel grating, also known as bar grating or metal grating, is an open grid assembly of metal bars, in which the bearing bars, running in one direction, are spaced by rigid attachment to cross bars running perpendicular to them or by bent connecting bars extending between them, which is designed to hold heavy loads with minimal weight. It is widely used as floors, mezzanines, stair treads, fencing, trench covers and maintenance platforms in factories, workshops, motor rooms, trolley channels, heavy loading areas, boiler equipment and heavy equipment areas, etc.

Steel grating is available in various material, such as stainless steel, aluminum, and galvanized steel. Among them, the galvanized steel grating is the most cost effective and economical type with long service life and high load. And it is the most widely used in both industrial, commercial and residential applications

High strength. The strength and toughness are much higher than cast iron. Can be used for terminals, airports and other large span and heavy load conditions.

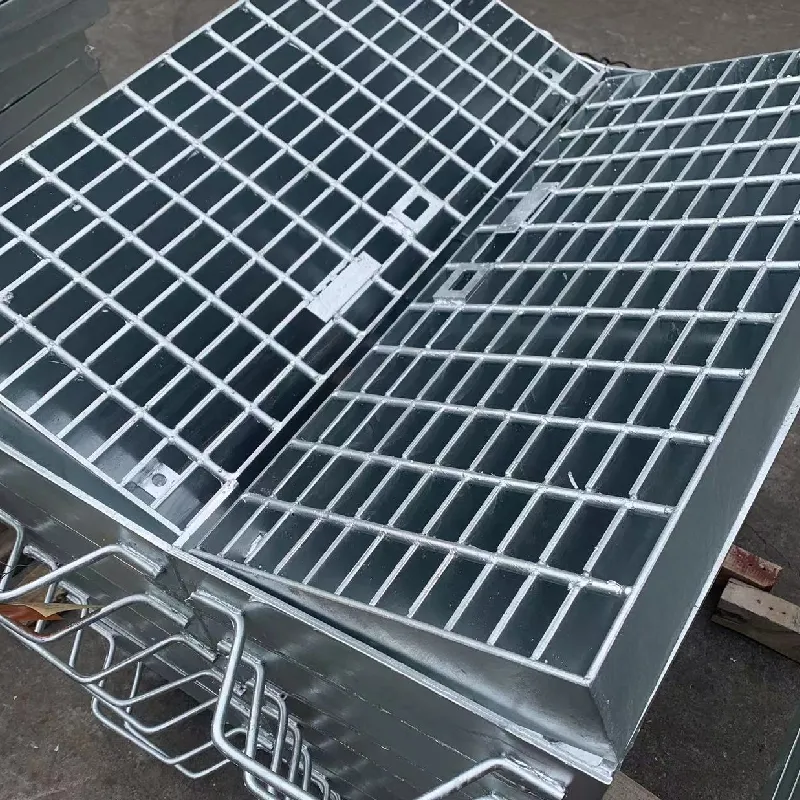

Hot-dip galvanised treatment. Good anti-rust property, maintenance-free replacement.

Anti-theft design. The cover and frame are hinged together, providing security, safety and ease of opening.

Saving investment. Large span. Less loss under heavy load compared to cast iron products. Costs can be saved for the risk of theft or crushing when using cast iron.

Aesthetic appearance. Sleek lines and silver finish fit the modern trend.

The best drainage. Leakage area of 83.3%, more than twice that of cast iron products.

Galvanised grating is designed and manufactured for use in a variety of industrial and civil construction projects, including city roads, gardens, yards, airports, railways and industrial engineering.Steel grating is a versatile material used in various applications due to its strength, durability, and ability to withstand heavy loads.

Related Product

News