Jul . 07, 2025 16:05 Back to list

Reinforcing Mesh: Core Material of the Construction Industry

What's Reinforcing Mesh

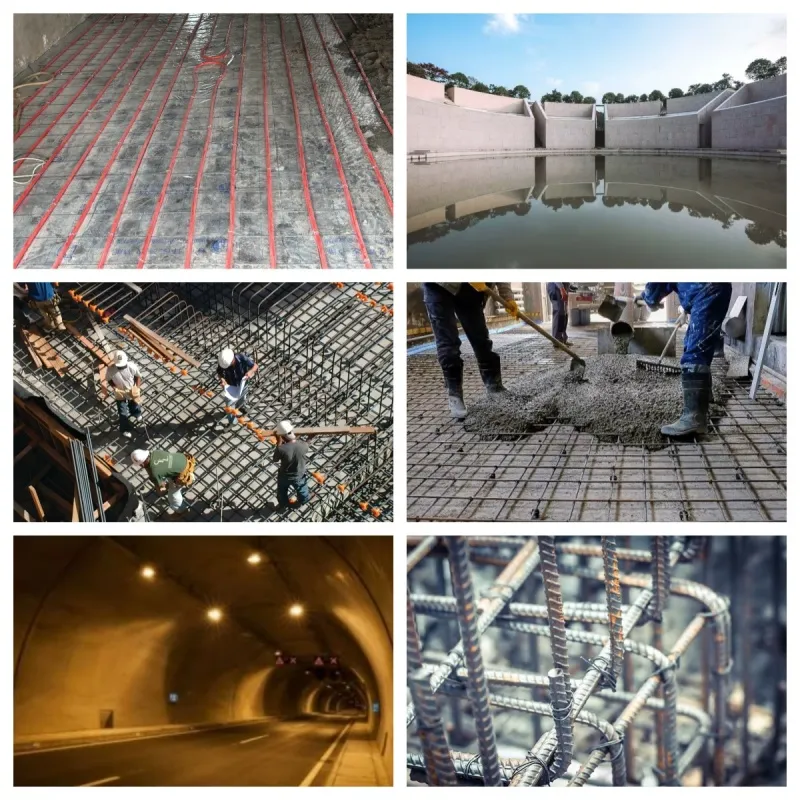

Reinforcing mesh, also known as welded reinforcing mesh or rebar mesh, is a structural mesh made from cold-drawn ribbed steel bars or hot-rolled grade 3 steel bars. It is used to improve concrete's tensile strength and stability. As a fundamental material across the construction industry, reinforcing mesh offers high strength, enhanced efficiency, and flexible customization. It plays a vital role in residential buildings, infrastructure, precast elements, and specialized engineering projects.

Why Choose Reinforcing Mesh?

1. Enhanced Structural Strength

Precise mesh spacing and strong welds ensure proper placement, reducing cracks and enhancing structural performance.

Manufactured with high-strength steel like HRB400/500 or Grade 500.

Complies with ASTM A1064, EN 10080, AS/NZS 4671, and other standards.

2. Improved Construction Efficiency

Factory-produced mesh panels minimize on-site work and boost productivity by over 50%.

Bangjun's automated welding systems complete each weld in 3 seconds or less.

3. Material and Cost Optimization

Optimized mesh design reduces material waste and project costs.

Lower labor requirements result in higher long-term cost efficiency.

4. High Customization Capability

Mesh size, bar diameter, spacing, and surface treatment (e.g., galvanization, epoxy) can be tailored for specific projects.

5. Standard Compliance

Products are certified by international bodies such as ACRS, ensuring seamless market access.

Application Scenarios and Technical Requirements

Residential & Commercial Construction

Use cases: High-rise housing, office towers, shopping malls (floors, beams, columns)

Key specs:

Yield strength: 400–500 MPa (HRB400/Grade 500)

Mesh spacing: 100–200 mm; bar diameter: 6–12 mm

Custom mesh size (e.g., 2m×6m), grid tolerance: ±5 mm

Weld shear strength: ≥250 kN/m²

Conforms to: GB/T 1499.3, ASTM A1064, EN 10080

Special case: High ductility (≥12%) for seismic zones like California or Japan

Bangjun Advantage: Precise mesh fabrication and rapid delivery for EU and U.S. housing projects

Infrastructure: Roads, Bridges & Tunnels

Use cases: Highways, bridges, tunnels, runways

Key specs:

Yield strength: ≥500 MPa (HRB500/Grade 60)

Mesh spacing: 150–300 mm; bar diameter: 8–16 mm

Mesh size: up to 3m×12m

Coating thickness: ≥85μm (galvanized or epoxy)

Fatigue resistance: Passed 5,000 loading cycles

Standards: AS/NZS 4671, BS 4483, AASHTO

Special case: Pre-bent mesh (±2°) for tunnel curves

Bangjun Advantage: ACRS certification, 10-container daily capacity, suited for large infrastructure builds

Precast Components

Use cases: Precast slabs, pipe galleries, culverts, columns

Key specs:

Yield strength: 400–600 MPa

Mesh spacing: 100–150 mm; bar diameter: 6–10 mm

Mesh fit: Custom-sized to molds (e.g., 1.5m×3m), tolerance: ±2 mm

Weld strength: ≥300 kN/m²

Surface: Flat and burr-free

Standards: EN 10080, ASTM A1064, GB/T 1499.3

Special case: Mesh with holes or complex shapes

Bangjun Advantage: Laser welding for tight tolerances; tailored designs for prefab markets in the EU and U.S.

Special Projects: Marine, Mining & Waterworks

Use cases: Sea defenses, docks, mine shafts, dams, industrial floors

Key specs:

Yield strength: ≥600 MPa (HRB600/Grade 60)

Mesh spacing: 100–300 mm; bar diameter: 10–20 mm

Mesh size: up to 4m×12m

Coating: Zinc ≥100μm or epoxy ≥150μm

Tested: Salt spray (ASTM B117); suitable for extreme heat/humidity

Standards: BS 4449, AS/NZS 4671, CSA G30.18

Special case: Pre-stressed or pre-bent mesh for irregular installations

Bangjun Advantage: Coated mesh for corrosion-heavy environments like UAE ports and Australian coasts

Why International Buyers Choose Bangjun

Certified Compliance

Meets ASTM A1064 (U.S.), EN 10080 (EU), AS/NZS 4671 (Australia/NZ)

Provides ACRS certificates and third-party test reports

Customization & Versatility

Flexible product configurations for diverse climates and applications

Suitable for both residential and high-spec infrastructure projects

Competitive Pricing & Value

Efficient automation reduces labor and material usage

High ROI through durability and minimized site work

Large-Scale Supply Chain

Daily output of 10 containers

Experienced logistics for fast, reliable delivery worldwide

Durability for Extreme Environments

Galvanized and epoxy-coated options

Engineered for coastal, desert, and high-stress settings

Technical & Customer Support

Pre-sales consultation, on-site support, and after-sales service

Trusted by long-term partners across the U.S., EU, and Middle East

Contact us today for custom orders or technical inquiries: sai@bangjunmetal.com

products.