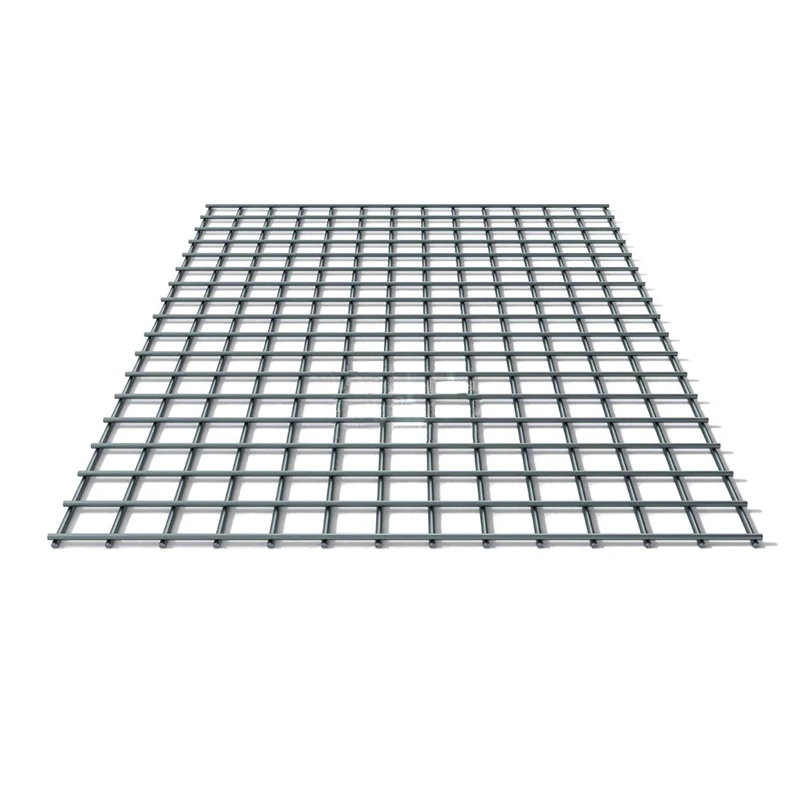

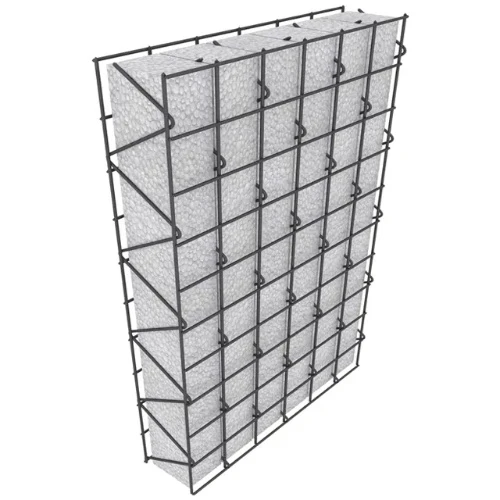

Weld mesh, also known as welded wire mesh, is a type of metal mesh made by welding together intersecting wire strands at right angles. The wires are welded at each point of intersection, creating a strong, uniform grid structure. Weld mesh is commonly used in a variety of applications due to its strength, versatility, and durability. It is widely used in construction, where it serves as reinforcement for concrete, helping to provide additional support and preventing cracks. In fencing, weld mesh is used to create secure enclosures for residential, commercial, and industrial purposes, such as boundary fences, animal enclosures, and security barriers. It is also used in agricultural applications to build cages or pens for livestock or to protect crops from animals. Additionally, weld mesh is utilized in the manufacturing of shelves, racks, and partitions in industrial settings. Its uniform pattern and durability make it ideal for applications requiring both strength and flexibility. Weld mesh is also used in the production of safety barriers and partitions in public spaces, where it is important to maintain both visibility and security. Overall, weld mesh is a highly versatile material used in construction, agriculture, manufacturing, and security.

What Are the Benefits of Using Weld Mesh?

Weld mesh offers several benefits that make it a popular choice across various industries. One of the primary advantages is its strength and durability. The welding process ensures that the mesh remains solid and resistant to mechanical stress, making it suitable for heavy-duty applications. Weld mesh is also highly versatile and can be used in a wide range of settings, including construction, security, and agriculture. It can be easily customized in terms of wire thickness, mesh size, and material type to suit specific requirements. Another benefit is its resistance to corrosion. Many weld mesh products are made from galvanized steel, stainless steel, or coated with protective layers, which enhances their longevity and performance, especially in outdoor or harsh environments. Weld mesh is also easy to install and maintain, reducing labor costs and ensuring a cost-effective solution for various applications. Its uniform grid pattern makes it aesthetically appealing and functional, especially when used for fences or barriers where both security and visibility are important. Additionally, weld mesh is a sustainable material as it can be recycled, which makes it an environmentally friendly option. In summary, weld mesh is strong, durable, versatile, and low-maintenance, offering a reliable solution for a variety of applications.

How Does Weld Mesh Compare to Other Types of Fencing or Reinforcement Materials?

Weld mesh offers distinct advantages compared to other types of fencing or reinforcement materials, particularly in terms of strength, flexibility, and ease of installation. Compared to traditional wooden fences, weld mesh is more durable and requires less maintenance. Wooden fences can warp, rot, or be damaged by pests, whereas weld mesh made from galvanized or stainless steel is resistant to weathering, corrosion, and physical damage, making it a more long-lasting solution. When compared to chain link fences, weld mesh provides better security due to its more robust structure and tighter mesh pattern, which makes it more difficult for intruders or animals to pass through. Additionally, weld mesh offers a cleaner, more modern appearance, which can be an advantage in urban or residential settings. In terms of reinforcement, weld mesh is stronger than traditional wire mesh or rebar and can be used in concrete to provide superior support. It is also more flexible than rigid reinforcement methods, such as steel bars, and can be customized to suit specific project needs. Unlike wood or PVC fencing, weld mesh allows for visibility while still maintaining security, making it ideal for areas where sightlines are important, such as sports fields or public spaces. Overall, weld mesh is a more durable, secure, and flexible option compared to other materials, offering better performance in a wide range of applications.