MZP Putanka Anti-Tank Wire Mesh

Product Features

Long Service Life

Made with high-tensile steel wire and treated with hot-dip galvanizing or PVC coating, the MZP Putanka is engineered to resist rust, corrosion, and harsh weather conditions. It maintains structural integrity over years of outdoor use.

Excellent Concealment in Terrain

Its non-reflective, tangled design blends seamlessly into natural landscapes, deserts, forests, and rocky areas, making it ideal for tactical use where visual detection must be minimized.

Highly Effective Physical Barrier

The dense, chaotic structure creates a formidable entanglement, capable of delaying or completely blocking the passage of light vehicles, personnel, and even light armored threats. It slows intruders down significantly, giving security forces more time to respond.

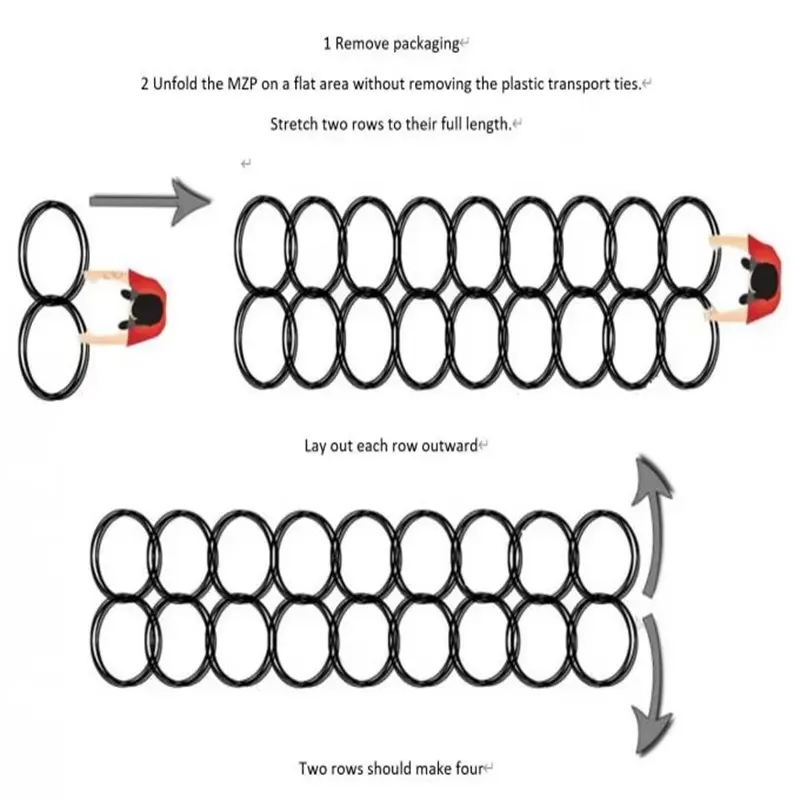

Tool-Free, Rapid Deployment

Supplied in compressed, ready-to-use bundles, this system requires no welding, posts, or tools. It can be deployed by 2–3 people in minutes, making it ideal for emergency or battlefield use.

Modular & Scalable

Units can be linked or layered for larger protection areas or enhanced barrier thickness, depending on threat level and mission requirement.

Customizable for Diverse Climates

Available in different wire gauges, net heights, and coatings, suitable for dry, humid, coastal, or mountainous environments.

Technical Parameters

To enhance the destructive capability against tanks, spikes or blades can be added to the surface.

|

Specification |

Description |

|

Wire Material |

High-carbon galvanized steel |

|

Wire Diameter |

2.5 mm – 4.0 mm |

|

Roll Length |

10 m – 50 m per unit |

|

Net Height |

1.0 m – 2.4 m |

|

Surface Finishes |

Hot-dip galvanized / PVC coated |

|

Packing Method |

Compressed bundles / Wooden or Steel Pallet |

📌 Custom designs, diameters, colors, and packaging available upon request.

Installation Guide for MZP Putanka Wire Barrier

By Bangjun – Trusted Wire Mesh Manufacturer in China

🔧 Installation Method

Site Preparation

Choose a stable, level ground to ensure structural integrity.

Clear debris, vegetation, or any loose materials that may interfere with barrier anchoring.

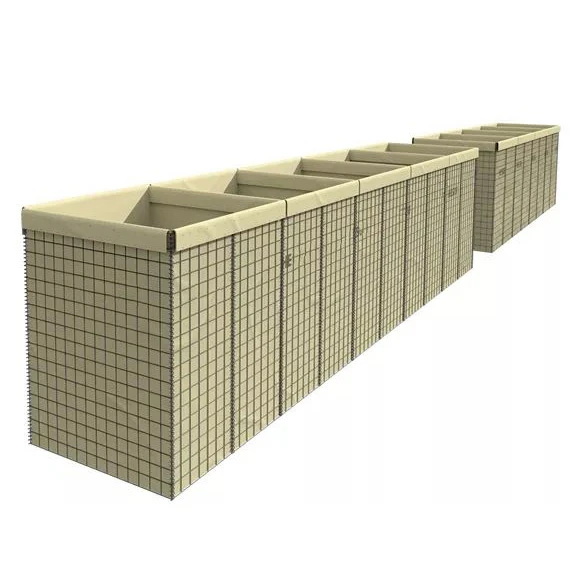

Positioning the Modules

Each MZP Putanka unit is typically pre-fabricated and folded.

Unfold the sections along the planned defense line. Align the barrier units with their connection points.

Fixing the Base

Anchor the base frame firmly using steel stakes or ground bolts, depending on soil type.

For sand or soft ground, use deep stakes or reinforced ground plates.

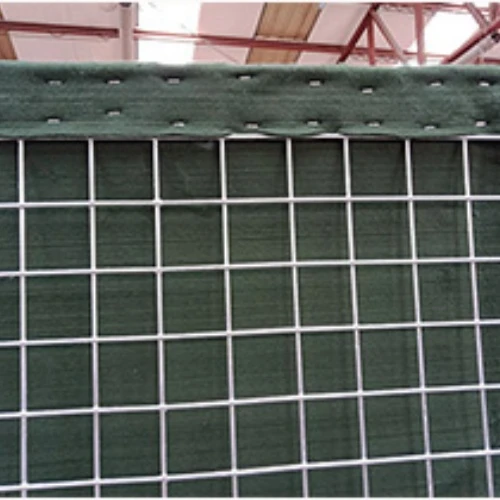

Securing the Wire Netting

The barbed wire mesh should be stretched tightly across the frame.

Use tension wires or steel rods to reinforce each segment and avoid sagging.

Connecting Multiple Units

Connect adjacent modules using binding wire, steel clamps, or welding (depending on the requirement).

Ensure no gaps remain between sections to maintain a continuous barrier.

Final Check

Inspect the entire structure for any loose fittings or uneven sections.

Apply anti-rust coating if required, especially in humid or coastal areas.

⚠️ Installation Tips & Safety Considerations

Always wear protective gloves and eye gear when handling barbed wire.

Ensure all stakes and fasteners are rust-resistant and suitable for the climate.

Avoid installation during extreme weather (heavy rain, strong winds).

For large-scale deployment, a two-person team is recommended for safety and efficiency.

If installed in public or urban areas, warning signs should be placed for visibility and legal compliance.

Application Areas

Military Perimeter Defense

Anti-Tank and Vehicle Control Zones

Temporary Field Barriers

Conflict Zone Protection

Border Surveillance & Separation Lines

Embassy, Oil Field & Critical Asset Security

Frequently Asked Questions (FAQ)

Q1: What is the difference between MZP Putanka and Concertina Razor Wire?

A: MZP Putanka is designed for vehicle stoppage and features a dense, tangled mass of wire mesh. Concertina Razor Wire primarily targets personnel and has uniform, spiral blade coils.

Q2: How many people are needed to install one unit?

A: For a 20–30 meter roll, 2–3 trained personnel can deploy it within 10–15 minutes without heavy machinery.

Q3: Can you provide CAD drawings or installation diagrams?

A: Yes. Bangjun provides detailed CAD layouts, structural diagrams, and technical guidance to assist your team in both fixed and rapid deployment scenarios.

Q4: How do I choose the right specifications for my project?

A: Our sales engineers will assess your project location, threat level, and deployment method to recommend the right wire diameter, net height, and surface treatment.

Q5: How is the product packaged and shipped internationally?

A: We use compressed bundles on steel pallets or wooden crates. All products are container-friendly and come with export documentation (CO, packing list, invoice, B/L, etc.).

Why Parter With Bangjun?

Bangjun is more than a wire mesh manufacturer — we are your integrated security solution partner.

🔧 We Offer:

OEM & ODM Services with logo and packaging customization

One-stop Defense Supply: razor wire, hesco barriers, putanka nets

Fast Lead Time: large inventory + automated production lines

Experienced Export Team: fluently English communication, full documents support,We also sell products in Portuguese, Italian, Japanese, Spanish and other small languages

Military-Level QC: strict product inspection before shipment

Contact Us Today

Let us help you build a secure perimeter with a proven, field-tested solution.

📧 Email: sai@bangjunmetal.com

👉 Request a Free Quote or Technical Drawing Today.

Related Product

News