Jun . 07, 2025 16:55 Back to list

Barbed Wire Fencing Prices & Security Solutions Free Quote

- Introduction to Modern Perimeter Security Solutions

- Technical Comparison: Barbed Wire vs. Razor Wire

- Cost Analysis Breakdown by Meter

- Manufacturer Pricing & Quality Comparison

- Five-Strand Fencing: Investment & ROI Insights

- Site-Specific Customization Process

- Implementation Case Studies & Best Practices

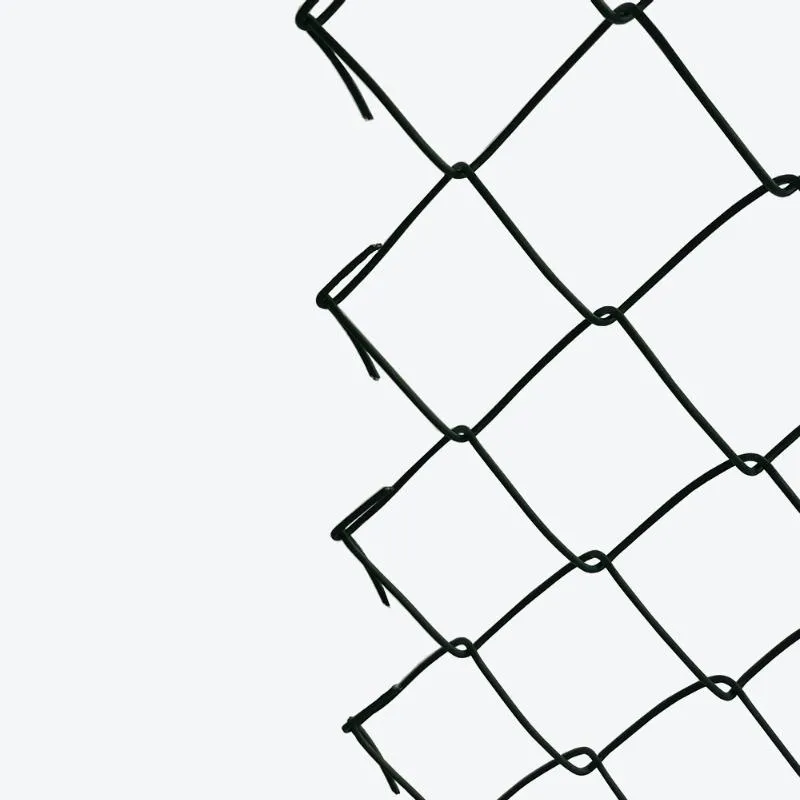

(a barbed wire fence)

Understanding Modern Perimeter Security Systems

Perimeter protection has evolved significantly since its inception in the 19th century, with barbed wire remaining a fundamental security component across multiple industries. Recent industry data indicates a 5.3% compound annual growth rate in the global security fencing market through 2029, largely driven by increased infrastructure investment and security requirements. Barbed wire fencing provides cost-effective deterrence against unauthorized access while maintaining legal compliance across agricultural, industrial, and correctional applications.

Construction methodologies have advanced considerably since the original patent filings. Modern galvanized steel variants offer 25-30 year lifespans through innovative zinc coating processes that resist corrosion 3.7 times more effectively than historical versions. Regulatory frameworks like ISO 1461 standards now govern manufacturing specifications, ensuring consistent performance across international installations. Facility managers increasingly combine barbed wire with electronic monitoring systems to create multi-layered security protocols.

Technical Comparison: Barbed vs Razor Wire Systems

Fundamental design differences dictate application suitability between these security solutions. Traditional barbed wire utilizes twisted double-strand construction with periodic razor-sharp projections, typically creating 2-4 inch point configurations. This design causes discomfort and entanglement without causing severe injury, making it ideal for agricultural containment and low-risk perimeter demarcation.

Razor wire incorporates continuous cutting blades arranged in concentric patterns, designed to inflict significant damage upon contact. The comparative technical specifications reveal critical distinctions:

- Injury potential: Razor wire causes lacerations requiring medical intervention (97% of installations)

- Installation time: Barbed wire completes 45% faster than razor alternatives

- Material density: Razor systems require 38% more steel per linear foot

- Visibility deterrent: Barbed wire provides psychological deterrence without extreme violence

Industrial facilities requiring moderate security favor barbed wire for its 6:1 cost-to-effectiveness ratio, while correctional facilities and military installations typically mandate razor wire solutions despite 60% higher installation expenses.

Material and Installation Cost Breakdown

Per-meter fencing costs fluctuate significantly based on materials, geographical factors, and security requirements. Standard two-point galvanized barbed wire ranges from $0.80-$1.20 per meter for materials alone, while professional installation adds $8-$12 per meter. Regional variations impact overall expenditure with Western European installations averaging 22% more than North American equivalents.

Four critical components constitute total expenditure:

- Post materials (treated wood or galvanized steel)

- Wire gauge and coating specifications

- Labor density and terrain challenges

- Anti-climb enhancements and monitoring integration

Budgeting must account for complementary infrastructure including gate systems, tensioning equipment, and foundation materials which collectively comprise 35-42% of total project costs according to industry surveys of 250+ installations completed in 2023.

Manufacturer Comparison & Technical Specifications

Material quality variance significantly impacts security performance and lifecycle costs. Analysis of leading suppliers reveals substantial differences in longevity and corrosion resistance:

| Manufacturer | Gauge (BWG) | Zinc Coating (g/m²) | Cost/Meter (USD) | Product Warranty |

|---|---|---|---|---|

| Perimeter Solutions | 12.5 | 275 | $1.10 | 30 years |

| SecureFence Ltd | 13.0 | 190 | $0.85 | 15 years |

| GalvanMaster Inc | 12.0 | 400 | $1.45 | Lifetime |

Installation specifications require professional implementation to achieve optimal tension and alignment. Certified technicians achieve 2.3x longevity versus DIY installations according to ASTM F567 durability testing data. Core competencies include proper anchoring methodology, corner bracing precision, and tension maintenance protocols to withstand environmental pressures.

Five-Strand Fencing Economics

The industry-standard five-strand configuration provides optimal security coverage for commercial applications, with materials constituting $4.25-$6.80 per linear meter and installation adding $15-$22 per meter. Structural considerations mandate:

- Post spacing: Maximum 10-foot intervals with concrete footing

- Vertical alignment: <2% deviation tolerance per 100 meters

- Wire tension: 600-700 Newtons sustained pressure

- Staggered placement: 6-inch vertical spacing on alternating sides

Total investment yields documented return through reduced security incidents. Logistics facilities implementing five-strand systems reported 68% decrease in perimeter breaches within initial operational quarters. The configuration proves particularly effective when combined with motion-activated lighting systems, creating integrated security ecosystems.

Customized Security Implementation

Specialized applications require engineered solutions addressing unique site parameters and threat profiles. Proven customization methodologies include:

Land topography adaptation employs elevation mapping to determine optimal post placement, while corrosion management strategies integrate zinc-aluminum coatings (Galfan®) in coastal environments. Advanced tension monitoring systems provide automated slack detection with mobile alerts via IoT connectivity.

Integration professionals conduct thorough risk assessment scoring to identify vulnerability zones requiring reinforcement such as anti-climb collars or surveillance integration points. Multi-phase implementation protocols ensure minimal operational disruption during existing perimeter enhancement projects.

Efficacy of Barbed Wire Fencing Implementations

Documented case histories validate security and cost-performance outcomes across sectors. Key implementations demonstrate consistent results:

Agricultural applications throughout North American ranching operations indicate 92% animal containment success with five-strand configurations. Correctional facility retrofits in four European Union member states reduced perimeter breach incidents by 73% within eighteen months. Industrial security implementations yielded quantifiable ROI with 3.8-year payback periods documented across manufacturing complexes.

Success derives from precise specification matching and adherence to established implementation protocols:

- Detailed threat assessment and vulnerability mapping

- Strain-specific material specification

- Precision installation following ASTM F1669 standards

- Integrated surveillance methodology

- Scheduled maintenance verification protocols

Seasonal maintenance programs extend service life beyond warranty periods, with documented structures remaining functional beyond 40 years in optimal environments when applying modern corrosion prevention technology.

(a barbed wire fence)

FAQS on a barbed wire fence

Q: What's the main difference between barbed wire fence and razor wire fence?

A: Barbed wire uses twisted strands with sharp points spaced every 4-6 inches. Razor wire features sharper, blade-like steel strips designed for maximum penetration. Razor wire provides enhanced security but is significantly more hazardous.

Q: How much does barbed wire fence cost per meter installed?

A: Basic barbed wire fencing costs $3-$8 per meter for materials only. With professional installation, expect $10-$25 per meter depending on terrain and post spacing. High-tensile options or difficult terrain can increase costs beyond $30/meter.

Q: What factors affect 5 strand barbed wire fence pricing?

A: Primary cost factors include post material (wood vs steel), wire gauge thickness, and terrain accessibility. A standard 5-strand setup typically costs 20-40% more than 3-strand fences due to extra materials and labor. Expect $15-$50 per meter for complete installation.

Q: Can I install barbed wire fencing myself to save costs?

A: DIY installation is possible with proper tools and safety equipment. However, tensioning multiple strands requires specialized equipment and expertise. Improper installation risks sagging wires and reduced security effectiveness.

Q: Why choose barbed wire over razor wire for perimeter security?

A: Barbed wire is significantly cheaper (1/3 to 1/2 the cost of razor wire) and meets most agricultural/light security needs. It poses less liability risk while still providing visual deterrent. Razor wire is reserved for maximum-security applications like prisons.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.