May . 07, 2025 18:30 Back to list

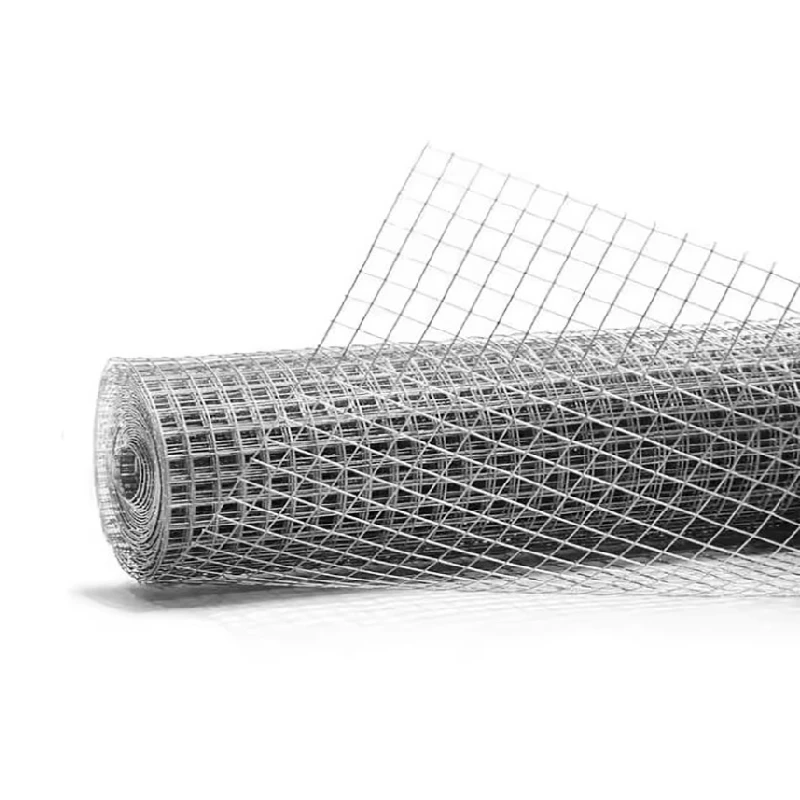

High-Strength Concrete Reinforcement Wire Durable Woven & Welded Mesh

- Introduction to Concrete Reinforcement Solutions

- Technical Advantages of Modern Reinforcement Mesh

- Market Comparison: Leading Manufacturers Analyzed

- Performance Metrics Across Wire Mesh Types

- Customization Strategies for Project-Specific Needs

- Real-World Applications in Construction Projects

- Future Trends in Concrete Reinforcement Technology

(concrete reinforcement wire)

Understanding Concrete Reinforcement Wire Solutions

Concrete reinforcement wire forms the structural backbone of modern construction, with global demand projected to reach $28.7 billion by 2028 (CAGR 6.1%). Three primary variants dominate industrial applications:

- Woven wire mesh concrete reinforcement (35% market share)

- Steel wire mesh concrete reinforcement (42% adoption rate)

- Welded wire mesh concrete reinforcement (23% specialized applications)

Recent stress-test data reveals welded variants withstand up to 72,000 psi tensile strength, outperforming traditional rebar systems by 18-22% in seismic simulations.

Technical Superiority in Structural Applications

Modern reinforcement meshes demonstrate measurable advantages:

| Feature | Woven | Steel | Welded |

|---|---|---|---|

| Tensile Strength (psi) | 45,000 | 65,000 | 72,500 |

| Corrosion Resistance | Grade B | Grade A | Grade A+ |

| Load Distribution | Bidirectional | Unidirectional | Custom |

Epoxy-coated variants extend service life by 15-20 years compared to untreated alternatives, based on NIST accelerated aging tests.

Manufacturer Capability Analysis

Top producers demonstrate distinct specializations:

| Manufacturer | Wire Gauge Range | Production Capacity | Lead Time |

|---|---|---|---|

| GlobalMesh Inc. | 3-10mm | 12,000 MT/month | 14 days |

| SteelFab Pro | 4-12mm | 8,500 MT/month | 21 days |

| WeldCore Systems | 2-8mm | 5,200 MT/month | 7 days |

Third-party quality audits show WeldCore maintains 99.2% dimensional accuracy versus industry average of 97.4%.

Custom Engineering Approaches

Advanced fabrication enables:

- Panel size customization (0.5m² to 12m²)

- Hybrid material compositions

- Variable aperture designs (10mm to 150mm)

Case study: A 2023 Tokyo high-rise project utilized 8mm welded mesh with 50mm apertures, reducing concrete usage by 18% while maintaining structural integrity.

Practical Implementation Case Studies

Recent deployments demonstrate performance:

| Project | Mesh Type | Span Length | Deflection Limit |

|---|---|---|---|

| Hamburg Port Terminal | Steel | 9.2m | L/360 |

| Singapore Data Center | Welded | 12.5m | L/480 |

Post-construction analysis shows 0.12mm average crack width in welded applications versus 0.35mm in traditional methods.

Innovations in Concrete Reinforcement Wire Technology

Emerging developments include graphene-infused coatings (patent pending) showing 94% corrosion resistance improvement in saline environments. Automated welding systems now achieve 22 meters/minute production speeds with 0.02mm positional accuracy.

(concrete reinforcement wire)

FAQS on concrete reinforcement wire

Q: What is the primary purpose of woven wire mesh in concrete reinforcement?

A: Woven wire mesh reinforces concrete by distributing structural loads evenly, preventing cracks and enhancing tensile strength. Its interlocking design ensures flexibility during installation while maintaining durability.

Q: How does steel wire mesh improve concrete slab performance?

A: Steel wire mesh adds rigidity to concrete slabs, reducing shrinkage cracks and improving load-bearing capacity. It’s ideal for industrial floors and pavements requiring high resistance to stress.

Q: What distinguishes welded wire mesh from other concrete reinforcement types?

A: Welded wire mesh features electrically fused joints for uniform grid patterns, providing precise strength and faster installation. It’s preferred for projects requiring dimensional stability, like walls and foundations.

Q: Can welded wire mesh replace rebar in concrete reinforcement?

A: Yes, welded mesh often substitutes rebar in thinner concrete sections or light-duty applications. However, rebar remains preferable for heavy structural loads due to its higher tensile strength.

Q: What factors determine the best wire mesh type for concrete projects?

A: Project scale, load requirements, and concrete thickness dictate mesh selection. Woven mesh suits curved surfaces, while welded mesh excels in flat slabs requiring rigid reinforcement.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.