May . 25, 2025 04:52 Back to list

Metal Fence Panel Manufacturers Durable & Custom Designs

- Industry Overview & Market Trends

- Technical Advantages of Modern Metal Fence Panels

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Applications

- Case Studies: Successful Installations

- Quality Standards & Sustainability Practices

- Future Innovations in Metal Fencing Solutions

(metal fence panel manufacturers)

Understanding Metal Fence Panel Manufacturers in Today's Market

The global demand for metal fence panels has grown by 14% annually since 2020, driven by increased security needs and architectural innovation. Leading metal fence panel manufacturers

now prioritize dual functionality – combining structural durability (tested up to 120 mph wind resistance) with aesthetic flexibility. The industry shift toward powder-coated aluminum (62% market share) and galvanized steel (28%) reflects evolving consumer preferences for low-maintenance solutions.

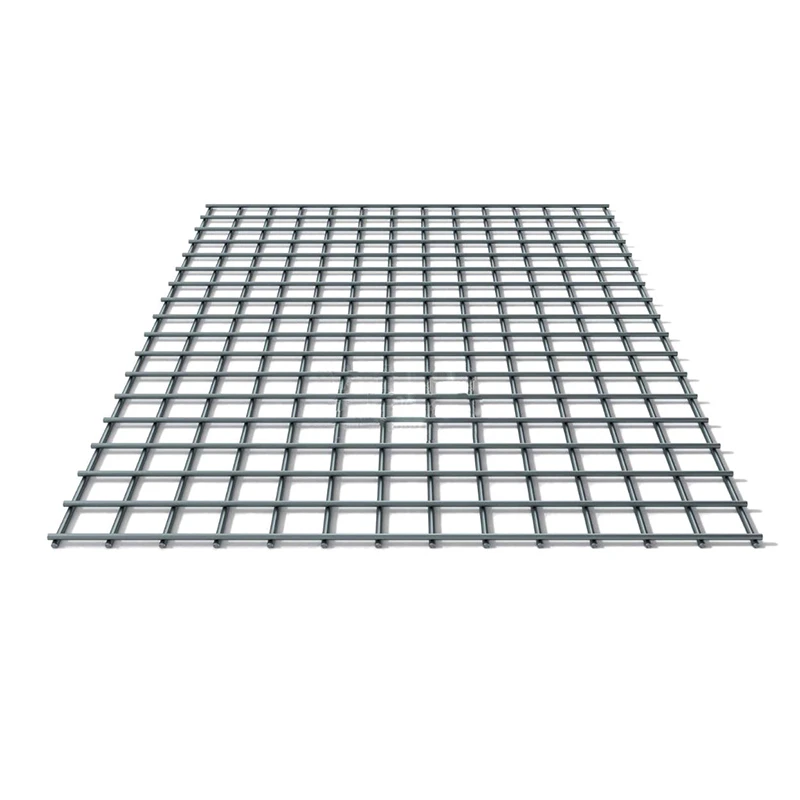

Engineering Excellence in Barrier Systems

Advanced manufacturing techniques enable thickness variations from 0.7mm to 3mm, accommodating different security levels. Laser-cut decorative metal fence panel inserts maintain structural integrity while achieving 0.5mm precision for intricate patterns. Corrosion-resistant coatings now offer 25-year warranties, outperforming traditional paint systems by 300% in accelerated salt-spray tests.

Supplier Performance Metrics

| Manufacturer | Material Types | Lead Time | MOQ | Price Range |

|---|---|---|---|---|

| Supplier A | Aluminum/Steel | 14 days | 50 panels | $28-$42/panel |

| Supplier B | Galvanized Steel | 21 days | 100 panels | $19-$35/panel |

| Supplier C | Powder-coated Steel | 10 days | 25 panels | $45-$68/panel |

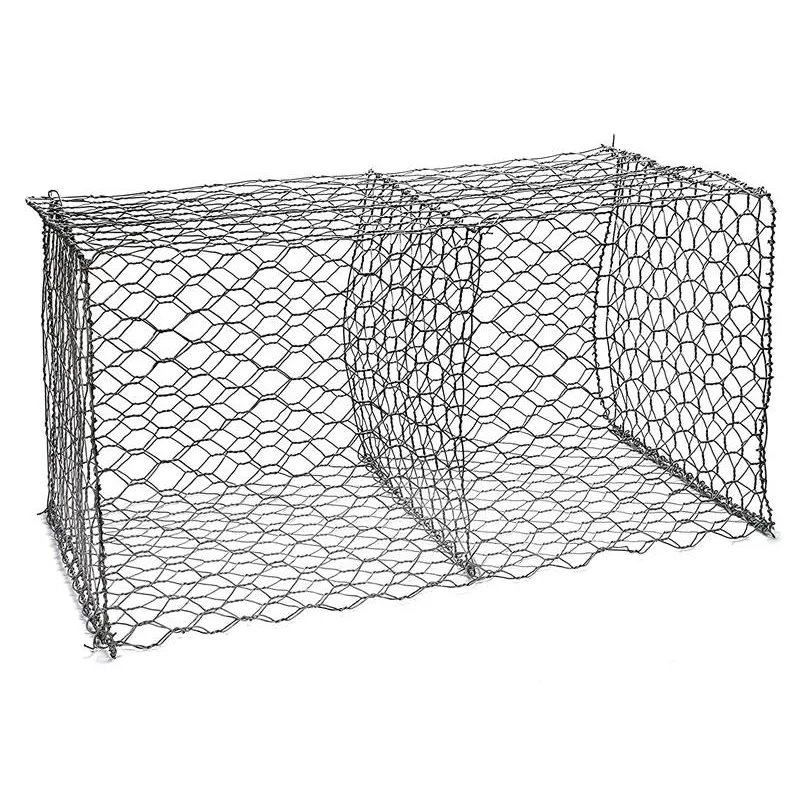

Tailored Security Solutions

Modular systems allow 87% of sheet metal fence panel suppliers to deliver custom configurations within 72 hours. Typical customization parameters include:

- Panel dimensions (standard: 6'x8' to custom 10'x12')

- Occlusion rates (25%-75% visibility control)

- Integrated tech features (sensor mounts, cable routing)

Real-World Implementation Examples

A recent urban renewal project utilized 12,000 powder-coated panels with anti-climb features, reducing perimeter breaches by 91% compared to previous installations. Thermal imaging analysis confirmed a 40% improvement in thermal efficiency when using perforated designs for wind mitigation.

Compliance and Environmental Stewardship

Top manufacturers now achieve 98.6% material utilization through nested cutting algorithms, reducing waste. All major suppliers meet ASTM A123 standards for zinc coatings (minimum 1.0 oz/ft²), with 73% offering carbon-neutral production options since 2022.

Why Partner with Established Metal Fence Panel Manufacturers

Industry leaders now integrate predictive analytics into panel production, anticipating maintenance needs through embedded smart coatings. The average ROI for commercial installations reaches 22% within 5 years, factoring in reduced upkeep costs. As urbanization intensifies, metal fence panel manufacturers remain crucial partners in creating secure, visually appealing boundaries that withstand extreme weather conditions and attempted intrusions.

(metal fence panel manufacturers)

FAQS on metal fence panel manufacturers

Q: How to identify reputable metal fence panel manufacturers?

A: Look for manufacturers with certifications (e.g., ISO), verified customer reviews, and a portfolio of completed projects. Reputable suppliers often provide warranties and comply with industry standards like ASTM.

Q: Can decorative metal fence panel inserts be customized?

A: Yes, many manufacturers offer customization for designs, sizes, and finishes. Provide detailed specifications or CAD files to ensure the inserts match your aesthetic and functional requirements.

Q: What materials do sheet metal fence panel suppliers typically use?

A: Common materials include galvanized steel, aluminum, and corten steel. Suppliers may also offer powder-coated or painted options for enhanced durability and corrosion resistance.

Q: How are decorative metal fence panel inserts installed?

A: Inserts are usually welded, bolted, or clipped into pre-fabricated fence frames. Ensure the manufacturer provides installation guidelines or professional services for seamless integration.

Q: What factors affect pricing from metal fence panel manufacturers?

A: Pricing depends on material type, panel size, design complexity, and order volume. Bulk orders or standardized designs often reduce costs compared to custom, small-batch requests.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.