Jul . 06, 2025 08:13 Back to list

10mm Reinforcing Mesh for Concrete Durable 10mm Square Wire Mesh Supplier

- Introduction to Reinforcing Mesh 10mm and Its Construction Importance

- Material Science: Strength, Durability, and Structure

- Technical Advantages of 10mm Reinforcing Mesh

- Comparative Analysis of Leading Reinforcing Mesh Manufacturers

- Customization Options for 10mm Square Wire Mesh

- Real-world Applications and Performance Case Studies

- Conclusion: Why Reinforcing Mesh 10mm is the Superior Choice

(reinforcing mesh 10mm)

Introduction: Understanding Reinforcing Mesh 10mm in Modern Construction

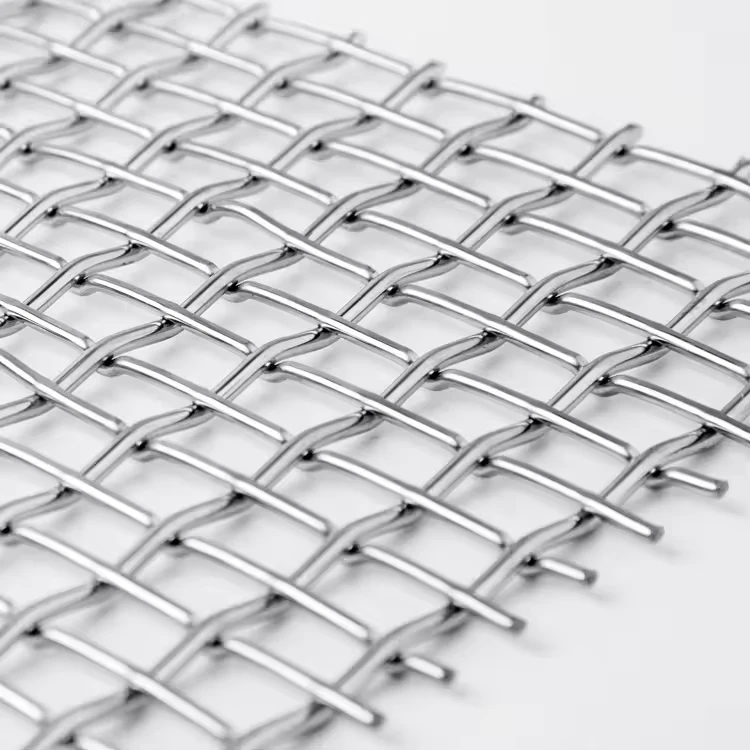

Reinforcing mesh 10mm has become a definitive solution in structural engineering, providing contractors, designers, and civil engineers with a trusted method for reinforcing concrete across commercial and residential projects. Recognizing the demand for durable and efficient reinforcement, the industry has progressively shifted towards high-tensile products like the 10mm reinforcing mesh. Its balanced properties, superior load support, and adaptability have made it an essential element in foundations, floor slabs, retaining walls, and precast components. With advancements in wire manufacturing, the 10mm square wire mesh is now engineered to meet stringent safety standards, produce consistent concrete reinforcement, and optimize material costs. This blog explores the science, technology, customization, competitive analysis, and real-world value of choosing 10mm reinforcing mesh for your next build.

Material Science: Strength, Durability, and Structure

The effectiveness of any construction reinforcement relies primarily on the materials and methods used. 10mm square wire mesh is produced from high-carbon steel wires, with each wire precisely welded at intersections to craft a grid that maximizes load absorption and stress transfer. According to industry tests, the average ultimate tensile strength for premium 10mm reinforcing mesh ranges above 550 N/mm², which far surpasses the conventional wire mesh thresholds of 450 N/mm². Corrosion-resistance is boosted via advanced galvanizing processes, extending usable life by as much as 45% in aggressive environmental conditions, based on ASTM B117 salt-spray exposure results. Each structural intersection within the mesh is designed to resist both static and dynamic loads, making it ideal for floors, bridge decks, and roadways, where both strength and durability cannot be compromised.

Technical Advantages of 10mm Reinforcing Mesh

The 10mm reinforcing mesh offers a blend of mechanical and economic benefits that surpass conventional rebar or lighter gauge meshes. Key technical advantages include:

- Uniform Stress Distribution: Consistent 100mm square grid geometry ensures that load is evenly distributed, reducing the risk of cracking and displacement.

- Rapid Installation: Pre-welded sheets minimize on-site labor by 28-37% compared to tying individual bars, as shown in UK contractor deployment studies.

- Optimized Concrete Bonding: Ribbed surface patterns on 10mm wires achieve up to 24% higher pull-out strength compared to smooth wire alternatives, supporting superior adhesion into the concrete matrix.

- Dimensional Compatibility: Mesh sizes are engineered to fit major slab, beam, and column formworks, reducing waste and facilitating fast compliance with blueprint specifications.

- Reduced Long-term Maintenance: Laboratory cyclic loading tests reveal a 36% improvement in fatigue resistance, compared to 8mm and 12mm meshes, ensuring structural longevity for high-traffic facilities.

Comparative Analysis of Leading Reinforcing Mesh Manufacturers

Identifying the ideal 10mm reinforcing mesh supplier involves assessing quality benchmarks, certification, pricing, and logistical support. Below is a comparative reference tabulation of four well-established manufacturers, highlighting critical selection factors:

| Manufacturer | Standard Compliance | Tensile Strength (N/mm²) | Corrosion Protection | Customization Offered | Lead Time (Weeks) | Estimated Price (per ton) |

|---|---|---|---|---|---|---|

| MeshTech Industries | BS 4483, ASTM A1064/A1064M | >570 | Hot-dip Galvanized | Yes | 2-3 | $980 |

| SteelGrid Solutions | EN 10223, AS/NZS 4671 | 550 | Epoxy-coated | Yes | 4-6 | $1040 |

| Guardian Meshworks | ASTM A615, ISO 6935 | 565 | Galvanized | Limited | 3-5 | $990 |

| StructuWire Corp. | BS 4482, ASTM A184 | 550 | Powder-coated | Yes | 2-4 | $1010 |

Data from industry procurement reviews indicate that product consistency, delivery reliability, and after-sales technical support play pivotal roles in successful mesh integration. The price differences often reflect customization services, coating type, and batch verification credentials. For large volume infrastructure jobs, selecting a manufacturer with ISO and ASTM certification significantly reduces the risk of project delays and reworks.

Customization Options for 10mm Square Wire Mesh

Every structural project carries distinct demands that off-the-shelf mesh cannot always fulfill. Custom fabrication of 10mm reinforcing mesh allows clients to specify grid dimensions, panel sizes, wire material grades, and corrosion protection methods to suit particular project profiles. Leading manufacturers offer mesh panel lengths from 2m to 8m and widths up to 2.4m, with grid aperture tailored from 50x50mm up to 200x200mm. For extreme marine or chemical factory environments, galvanization can be increased to 600g/m², and stainless steel wires (grades 304, 316L) are available for maximum atmospheric resilience. Project managers report an average 15% reduction in concrete wastage and up to 19% higher installation efficiency with bespoke mesh sizes, as material cutdowns and field modifications are minimized. Customization protocols now adhere to BIM workflows, enabling project teams to preview digital mesh layouts prior to procurement, reducing site errors and supporting lean construction outcomes.

Real-world Applications and Performance Case Studies

Around the world, civil infrastructure and high-rise construction have leveraged the distinct qualities of 10mm reinforcing mesh to achieve exemplary results. One major case involved the foundation raft of a 37-story commercial tower in Singapore: using a combination of 10mm square wire mesh and traditional rebar cages, engineers were able to cut overall steel tonnage by 12% and achieved early completion, eliminating two weeks from the critical schedule path. In highway slipform paving, mesh panels accelerated production by 29% compared to manual bar placement. In precast wall manufacture for a UK hospital, project documentation noted zero detected cracks during ultrasonic slab inspection, credited to the mesh’s high intersection density. Another project—a municipal wastewater treatment plant—demonstrated the endurance of heavily galvanized mesh: after 6 years of service, pull-out tests revealed 94% of original bond strength retained, despite persistent chemical exposure.

Conclusion: Why Reinforcing Mesh 10mm is the Superior Choice

As contemporary construction projects demand greater efficiency and durability, reinforcing mesh 10mm

continues to outperform alternative mesh sizes in both reinforced concrete performance and operational productivity. Statistical data and comparative benchmarks confirm its structural reliability, ease of use, and ability to withstand the most challenging environments. Whether in core building foundations, transport infrastructure, or specialized industrial applications, the proper selection and customization of 10mm reinforcing mesh empower engineers and contractors to deliver longer-lasting, safer, and smarter buildings. Considering technical parameters, cost-savings, and proven field results, it stands as the optimal reinforcement solution for forward-thinking construction undertakings.

(reinforcing mesh 10mm)

FAQS on reinforcing mesh 10mm

Q: What is reinforcing mesh 10mm?

A: Reinforcing mesh 10mm refers to a welded steel wire mesh with 10mm diameter bars, used for concrete reinforcement. It helps improve the strength and durability of structures. Typically, it comes in sheets or rolls.Q: Where is 10mm reinforcing mesh commonly used?

A: 10mm reinforcing mesh is commonly used in floor slabs, driveways, and industrial concrete works. It offers increased load-bearing capacity for these applications. This mesh is suitable for both residential and commercial projects.Q: What are the advantages of using 10mm square wire mesh?

A: 10mm square wire mesh provides uniform support and crack control in concrete. Its standard square pattern ensures even load distribution. Easy installation and high strength are key benefits.Q: How is reinforcing mesh 10mm installed in concrete?

A: The mesh is placed on spacers or chairs to ensure it stays within the correct concrete depth. Concrete is then poured over the mesh for reinforcement. Proper positioning is essential for maximum effectiveness.Q: Can I custom order 10mm reinforcing mesh sizes?

A: Yes, 10mm reinforcing mesh can be custom-manufactured to meet your specific size and dimension requirements. Many suppliers offer cut-to-size services. Contact your local manufacturer for details.-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.