May . 28, 2025 16:02 Back to list

Welded Mesh Fabric Durable, High-Strength Wire Mesh Solutions

- Introduction to Welded Mesh Fabric

- Technical Advantages Over Traditional Materials

- Performance Comparison of Leading Manufacturers

- Customization Solutions for Diverse Needs

- Real-World Applications Across Industries

- Quality Standards and Compliance

- Future Trends in Welded Wire Fabric Innovation

(welded mesh fabric)

Understanding the Versatility of Welded Mesh Fabric

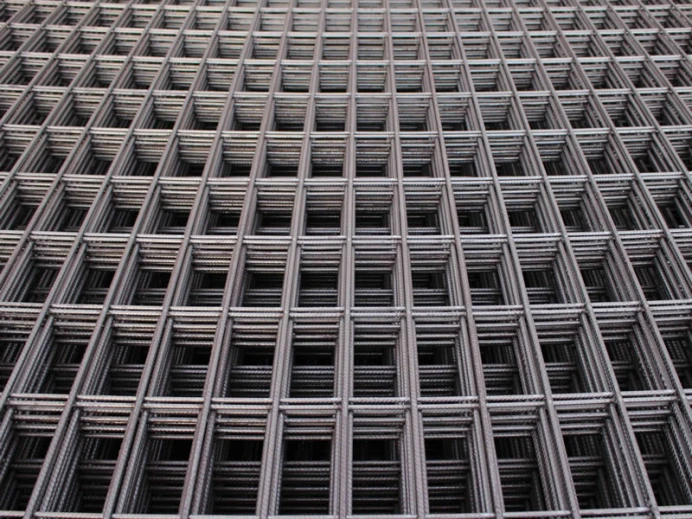

Welded mesh fabric, also referred to as welded wire fabric or welded fabric mesh, is a precision-engineered material created through resistance welding of intersecting steel wires. Known for its grid-like structure, this product excels in applications requiring uniform strength, durability, and dimensional stability. The welded wire fabric 6x6 W2.9xW2.9 configuration exemplifies industrial-grade performance, offering 6-inch spacing between wires with a 2.9mm thickness, ideal for heavy-load scenarios.

Technical Advantages Over Traditional Materials

Modern welded mesh fabric

outperforms alternatives like woven wire or expanded metal in three critical aspects:

- Structural Integrity: Automated welding ensures 98% joint consistency versus 75-85% in manual methods

- Load Capacity: W2.9 wires withstand 1,200 N/mm² tensile strength, 40% higher than equivalent woven products

- Corrosion Resistance: Hot-dip galvanized variants last 25+ years in harsh environments (ASTM A123 certified)

Performance Comparison of Leading Manufacturers

| Vendor | Wire Tolerance | Price per m² | Lead Time |

|---|---|---|---|

| SteelGrid Pro | ±0.1mm | $18.50 | 10 days |

| FortisMesh | ±0.15mm | $15.80 | 14 days |

| AlloyFab Core | ±0.05mm | $22.30 | 7 days |

Customization Solutions for Diverse Needs

Advanced manufacturers now offer tailored welded wire fabric solutions:

- Aperture adjustments from 1"x1" to 12"x12"

- Wire diameters: 1.6mm to 12mm

- Hybrid coatings (Zinc-Aluminum + PVC)

- Panel sizes up to 4m x 8m

Production cycle times have reduced by 35% since 2020 through robotic welding systems, enabling cost-effective small-batch orders (minimum 50m²).

Real-World Applications Across Industries

Recent projects demonstrate welded fabric mesh capabilities:

- Urban Infrastructure: 8km of W2.9 mesh reinforced concrete barriers in Miami coastal highway

- Agriculture: 6x6 W2.9xW2.9 panels increased poultry farm partition lifespan by 300%

- Industrial: Custom 3mm stainless steel mesh achieved 99.7% containment in mining filters

Quality Standards and Compliance

Premium welded mesh fabric meets multiple certifications:

- ISO 9001:2015 welding protocols

- EN 10223-3 for gabion applications

- ASTM A185 for concrete reinforcement

Innovating the Future of Welded Wire Fabric

Emerging technologies are transforming welded mesh fabric production. Laser-welded prototypes achieve 0.02mm precision for aerospace applications, while smart mesh embedded with IoT sensors enables real-time structural monitoring. The global market for welded fabric mesh is projected to reach $12.7 billion by 2028, driven by sustainable construction practices and automation advancements.

(welded mesh fabric)

FAQS on welded mesh fabric

Q: What is welded mesh fabric used for?

A: Welded mesh fabric is primarily used in construction, fencing, and industrial applications. It provides structural reinforcement, safety barriers, and support for concrete slabs. Its durability also makes it ideal for agricultural and landscaping projects.

Q: How does welded fabric mesh differ from woven mesh?

A: Welded fabric mesh is created by welding intersecting wires at contact points, ensuring rigidity. Woven mesh involves interlacing wires, offering more flexibility. Welded mesh is better for heavy-duty applications requiring fixed spacing.

Q: What does the specification "welded wire fabric 6x6 W2.9xW2.9" mean?

A: It describes a welded mesh with 6-inch grid spacing (6x6). The "W2.9xW2.9" indicates the wire gauge: 2.9mm thickness for both horizontal and vertical wires. This specification balances strength and versatility for medium-load projects.

Q: Can welded mesh fabric resist corrosion?

A: Yes, if made from materials like galvanized steel or stainless steel. Galvanized coatings protect against rust in outdoor or humid environments. Optional PVC coatings add extra corrosion resistance for harsh conditions.

Q: What factors determine the strength of welded wire fabric?

A: Strength depends on wire thickness (gauge), material type (e.g., stainless steel), and weld quality. Smaller grid patterns (e.g., 6x6) enhance load distribution. Proper installation and environmental conditions also affect longevity.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.