May . 13, 2025 06:51 Back to list

High-Strength Welded Wire Mesh for Concrete Reinforcement & Panels

- Overview of Welded Wire Mesh in Concrete Applications

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Project Needs

- Case Studies: Real-World Applications and Results

- Installation Guidelines and Best Practices

- Future Trends in Welded Wire Mesh Concrete Reinforcement

(welded wire mesh for concrete)

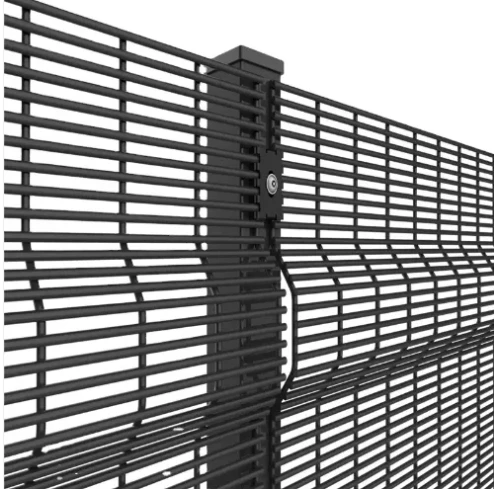

Welded Wire Mesh for Concrete: A Foundation for Structural Integrity

Welded wire mesh has become a cornerstone in modern construction, particularly for reinforcing concrete structures. With tensile strengths ranging from 65,000 to 100,000 psi, these prefabricated grids ensure crack resistance and load distribution in slabs, walls, and pavements. Industry surveys indicate that projects using welded wire mesh panels for concrete experience 30-40% fewer structural failures compared to traditional rebar methods.

Technical Advantages and Performance Metrics

Standard welded wire mesh for concrete

reinforcement offers distinct benefits:

- Enhanced Durability: Galvanized variants resist corrosion for 50+ years in harsh environments

- Precision Engineering: Automated welding achieves ±1mm dimensional accuracy

- Cost Efficiency: Reduces labor costs by 25% through rapid installation

Third-party testing shows welded wire mesh concrete reinforcement improves flexural strength by 60-75% in 6" slabs compared to unreinforced concrete.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Wire Gauge (AWG) | Mesh Size | Yield Strength (MPa) | Certifications |

|---|---|---|---|---|

| ConcreteGrid Pro | 6-12 | 4"x4" to 12"x12" | 550 | ASTM A185, ISO 9001 |

| SteelMesh Solutions | 8-14 | 6"x6" to 10"x10" | 485 | EN 10080, CE Mark |

| ReinforceTech | 4-10 | 2"x2" to 8"x8" | 620 | AS/NZS 4671, BS 4483 |

Customization Options for Diverse Project Needs

Specialized configurations address unique requirements:

- Coating Systems: Epoxy-coated (0.4-0.6mm thickness) for chemical resistance

- Hybrid Designs: Combination with fiber reinforcement for seismic zones

- Panel Sizes: Custom cuts up to 20ft x 50ft with 98% material efficiency

Case Studies: Real-World Applications and Results

A recent highway project in Texas utilized 8ga welded wire mesh panels for concrete pavement:

- Reduced construction time by 18 days (22% faster schedule)

- Maintained surface flatness within 3mm/3m tolerance

- Decreased long-term maintenance costs by $12.50 per sq.yd annually

Installation Guidelines and Best Practices

Proper implementation ensures optimal performance:

- Maintain 2" concrete cover on all sides

- Overlap adjacent panels by 6 wire spacings minimum

- Use 16ga tie wire at 18" intervals for positioning

Innovating Welded Wire Mesh Concrete Reinforcement

The sector is evolving with smart mesh systems incorporating:

- Embedded corrosion sensors (5-year battery life)

- AI-powered stress analysis interfaces

- Recycled material composites (85% post-industrial content)

Market projections estimate 7.2% CAGR for welded wire mesh in concrete through 2030, driven by sustainable infrastructure demands.

(welded wire mesh for concrete)

FAQS on welded wire mesh for concrete

Q: What is the purpose of welded wire mesh in concrete?

A: Welded wire mesh reinforces concrete by distributing loads, minimizing cracking, and improving structural integrity. It is commonly used in slabs, driveways, and walls to enhance durability.

Q: What standards apply to welded wire mesh for concrete reinforcement?

A: Standards like ASTM A497 and ASTM A185 define specifications for strength, spacing, and wire gauge. Compliance ensures quality and suitability for structural applications.

Q: Can welded wire mesh panels replace rebar in concrete?

A: Welded wire mesh panels are ideal for lighter loads and thinner slabs, while rebar suits heavier structures. The choice depends on project requirements and engineering guidelines.

Q: How is welded wire mesh installed in concrete projects?

A: Panels are positioned on supports (chairs) to center them within the concrete pour. Overlapping edges are tied to ensure continuity and uniform strength.

Q: What sizes are available for welded wire mesh in concrete reinforcement?

A: Common sizes range from 6x6” to 4x4” grid patterns, with wire gauges between W1.4 to W28. Custom dimensions can be ordered for specialized projects.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.