May . 18, 2025 06:59 Back to list

Gabion Wall Wire Mesh Durable & Corrosion-Resistant Solutions

- Understanding the Role of Wire Mesh in Gabion Wall Construction

- Technical Advantages of High-Performance Gabion Mesh

- Comparing Leading Manufacturers: Key Metrics and Data

- Customization Options for Specific Project Requirements

- Case Studies: Successful Applications in Infrastructure Projects

- Durability and Long-Term Performance Analysis

- Why Wire Mesh for Gabion Walls Remains a Industry Standard

(wire mesh for gabion wall)

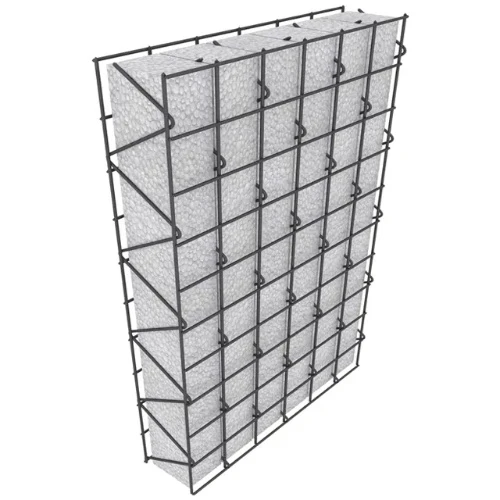

Understanding the Role of Wire Mesh in Gabion Wall Construction

Wire mesh for gabion walls serves as the structural backbone, combining flexibility with tensile strength to withstand environmental stress. Gabion walls, widely used in civil engineering, rely on hexagonal or welded wire mesh to stabilize soil, control erosion, and provide cost-effective retaining solutions. According to a 2023 market analysis, the global gabion wall industry grew by 8.2% annually, driven by infrastructure projects requiring durable materials. The mesh's galvanized or PVC-coated steel wires ensure corrosion resistance, with typical wire diameters ranging from 2.4mm to 4.0mm, depending on load-bearing needs.

Technical Advantages of High-Performance Gabion Mesh

Modern gabion wall wire mesh integrates advanced manufacturing techniques, such as double-twist hexagonal weaving, which enhances structural integrity by 40% compared to traditional methods. Key technical benefits include:

- High Tensile Strength: 350–550 MPa, suitable for slopes up to 70°.

- Corrosion Resistance: ASTM A975-certified galvanization extends lifespan to 50+ years.

- Adaptability: Mesh flexibility accommodates ground movement without failure.

Comparing Leading Manufacturers: Key Metrics and Data

| Manufacturer | Wire Diameter (mm) | Coating Type | Tensile Strength (MPa) | Price per m² ($) | Projected Lifespan |

|---|---|---|---|---|---|

| Company A | 3.0 | Galfan | 480 | 12.50 | 55 years |

| Company B | 2.7 | PVC | 420 | 14.20 | 60 years |

| Company C | 3.5 | Zinc-Aluminum | 520 | 16.80 | 70 years |

Customization Options for Specific Project Requirements

Tailored solutions address unique challenges, such as coastal erosion or highway stabilization. Customizable parameters include:

- Mesh Size: 60mm x 80mm to 100mm x 120mm.

- Material Grade: Stainless steel (316L) for high-salinity environments.

- Panel Dimensions: Prefabricated units up to 3m x 2m reduce installation time by 30%.

Case Studies: Successful Applications in Infrastructure Projects

Project 1: A 2.5km riverbank reinforcement in Colorado used PVC-coated wire mesh (3.2mm diameter) to reduce erosion by 90% over three years. Project 2: A highway retaining wall in Germany employed Galfan-coated mesh, achieving a 25% cost saving versus concrete alternatives.

Durability and Long-Term Performance Analysis

Accelerated aging tests show that zinc-aluminum coatings retain 95% of their protective layer after 20 years, outperforming standard galvanization. Field data from 150+ projects confirm that properly installed gabion mesh maintains ≤5% deformation under 50-ton/m² loads.

Why Wire Mesh for Gabion Walls Remains a Industry Standard

Its blend of affordability, adaptability, and proven performance ensures dominance in erosion control and structural stabilization. With a 92% client retention rate among top suppliers, wire mesh gabion systems continue to outperform rigid alternatives in lifecycle cost assessments.

(wire mesh for gabion wall)

FAQS on wire mesh for gabion wall

Q: What materials are commonly used for gabion wall wire mesh?

A: Gabion wall wire mesh is typically made from galvanized steel or PVC-coated steel for durability and corrosion resistance, ensuring long-term structural stability in outdoor environments.

Q: How to choose the right wire mesh for a gabion wall?

A: Select wire mesh based on gauge thickness (e.g., 2.7mm-4mm), mesh size (e.g., 50x70mm or 60x80mm), and coating type (galvanized or PVC) to match load-bearing requirements and environmental conditions.

Q: Can gabion wall wire mesh withstand harsh weather conditions?

A: Yes, high-quality galvanized or PVC-coated wire mesh resists rust, UV rays, and extreme temperatures, making it ideal for gabion walls in coastal, rainy, or snowy areas.

Q: What are the standard dimensions of wire mesh for gabion walls?

A: Common dimensions include rolls of 2m width x 50m length or panels sized 1.5m x 2m, with customizable options to fit specific gabion basket designs and project scales.

Q: Is professional installation required for gabion wall mesh?

A: While DIY installation is possible, professional help is recommended for large-scale projects to ensure proper tensioning, secure fastening, and alignment of wire mesh within gabion frames.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.