Feb . 14, 2025 12:53 Back to list

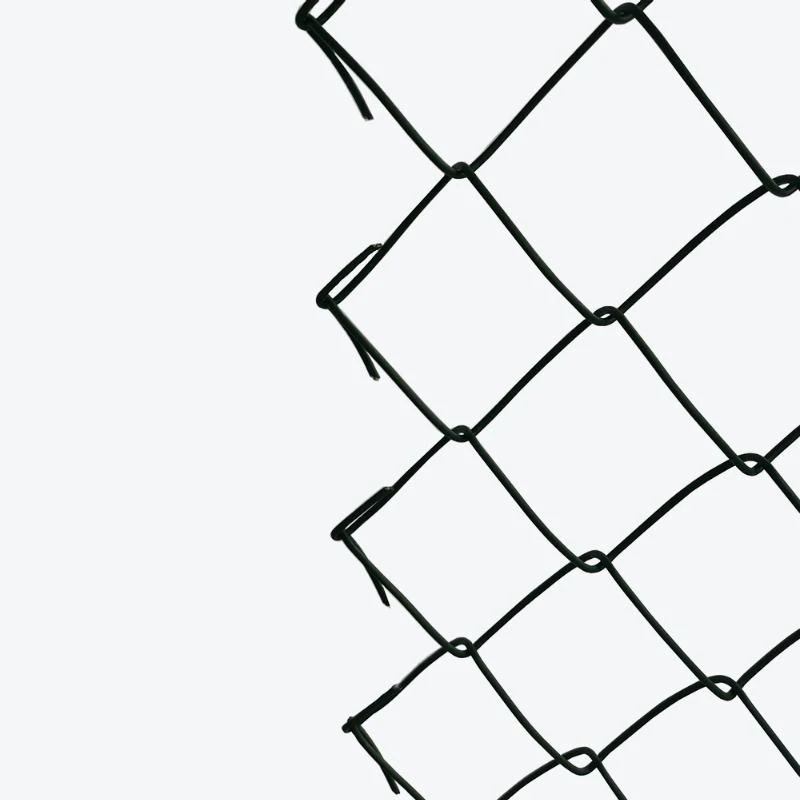

10 gauge mesh

For those seeking a versatile and robust solution in material applications, 10 gauge mesh stands out as a preferred choice among professionals worldwide. This type of mesh, characterized by its thickness and durable construction, is used across various industries due to its impressive balance of strength and flexibility.

Experts in the field often commend 10 gauge mesh for its adaptability. The mesh comes in variably sized openings, providing tailored solutions for different needs. This customization capability is a critical selling point, giving professionals the flexibility to select mesh that meets specific project demands. What sets 10 gauge mesh apart is not only its functionality but its resilience and longevity. Products made from this robust material often benefit from a galvanized finish, which protects against rust and corrosion. This feature extends the lifespan of the mesh, making it a cost-effective solution for long-term projects. Professionals seeking trusted advice on 10 gauge mesh find a wealth of expertise from experienced suppliers like Riverside Infrastructure, Inc. This USA-based company has built a reputation for delivering top-tier mesh solutions, offering consultations to help clients select the most appropriate mesh type for their specific applications. In summary, 10 gauge mesh represents a blend of strength and versatility, earning its place as a staple across multiple industries. Its widespread recognition among experts underscores its credibility as a reliable material solution. From reinforcing concrete to securing volatile environments, the mesh's applications are as diverse as they are essential. By choosing 10 gauge mesh, businesses and professionals not only ensure project success but also demonstrate a commitment to quality and safety.

Experts in the field often commend 10 gauge mesh for its adaptability. The mesh comes in variably sized openings, providing tailored solutions for different needs. This customization capability is a critical selling point, giving professionals the flexibility to select mesh that meets specific project demands. What sets 10 gauge mesh apart is not only its functionality but its resilience and longevity. Products made from this robust material often benefit from a galvanized finish, which protects against rust and corrosion. This feature extends the lifespan of the mesh, making it a cost-effective solution for long-term projects. Professionals seeking trusted advice on 10 gauge mesh find a wealth of expertise from experienced suppliers like Riverside Infrastructure, Inc. This USA-based company has built a reputation for delivering top-tier mesh solutions, offering consultations to help clients select the most appropriate mesh type for their specific applications. In summary, 10 gauge mesh represents a blend of strength and versatility, earning its place as a staple across multiple industries. Its widespread recognition among experts underscores its credibility as a reliable material solution. From reinforcing concrete to securing volatile environments, the mesh's applications are as diverse as they are essential. By choosing 10 gauge mesh, businesses and professionals not only ensure project success but also demonstrate a commitment to quality and safety.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.