Feb . 14, 2025 11:22 Back to list

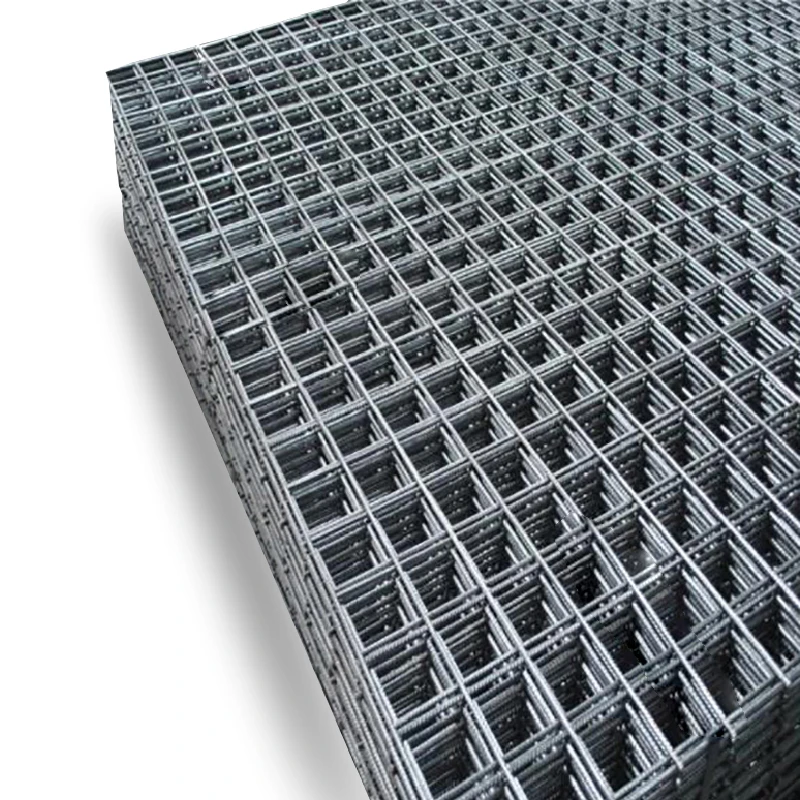

10 gauge mesh wire

When it comes to robust building materials, 10 gauge mesh wire stands out in the construction and security industries. This steel wire, with its balanced combination of flexibility and strength, offers versatile applications, making it a go-to solution for many professionals. Let's explore the unique properties, uses, and benefits of 10 gauge mesh wire while taking a closer look at why its popularity continues to rise.

The expertise of professionals working with 10 gauge mesh wire highlights its versatility. Contractors appreciate its ease of installation and the customizable nature of the wire in terms of size and shape. This adaptability allows for tailored solutions across diverse projects, from residential to industrial applications. Additionally, the wire’s compatibility with welding techniques simplifies construction processes, enhancing efficiency and reducing labor costs. Another feature that solidifies the authority of 10 gauge mesh wire in the industry is its safety profile. Its use in safety barriers and guardrails confirms its reliability in protecting both people and property. The wire not only provides a physical barrier but also offers visibility, ensuring that safety measures are both effective and unobtrusive. The trustworthiness of 10 gauge mesh wire is evident in the numerous regulations and standards it meets. These include ASTM specifications that ensure the wire's quality, strength, and suitability for construction purposes. Compliance with such standards assures users of the material’s reliability and performance, reinforcing confidence in its application in critical infrastructures such as bridges, highways, and public spaces. In summary, 10 gauge mesh wire serves as a testament to innovation in material science. Its combination of durability, flexibility, and applicability across multiple industries makes it an indispensable resource. The structured expertise, authoritative application, and proven trustworthiness of 10 gauge wire continually enhance its reputation, solidifying its standing as a vital component in construction, security, and art. As advancements in manufacturing and applications continue, this material's relevance and utility are expected to expand, meeting the evolving needs of future projects and innovations.

The expertise of professionals working with 10 gauge mesh wire highlights its versatility. Contractors appreciate its ease of installation and the customizable nature of the wire in terms of size and shape. This adaptability allows for tailored solutions across diverse projects, from residential to industrial applications. Additionally, the wire’s compatibility with welding techniques simplifies construction processes, enhancing efficiency and reducing labor costs. Another feature that solidifies the authority of 10 gauge mesh wire in the industry is its safety profile. Its use in safety barriers and guardrails confirms its reliability in protecting both people and property. The wire not only provides a physical barrier but also offers visibility, ensuring that safety measures are both effective and unobtrusive. The trustworthiness of 10 gauge mesh wire is evident in the numerous regulations and standards it meets. These include ASTM specifications that ensure the wire's quality, strength, and suitability for construction purposes. Compliance with such standards assures users of the material’s reliability and performance, reinforcing confidence in its application in critical infrastructures such as bridges, highways, and public spaces. In summary, 10 gauge mesh wire serves as a testament to innovation in material science. Its combination of durability, flexibility, and applicability across multiple industries makes it an indispensable resource. The structured expertise, authoritative application, and proven trustworthiness of 10 gauge wire continually enhance its reputation, solidifying its standing as a vital component in construction, security, and art. As advancements in manufacturing and applications continue, this material's relevance and utility are expected to expand, meeting the evolving needs of future projects and innovations.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.