Feb . 16, 2025 11:42 Back to list

3D EPS Welded Wire Mesh Panel

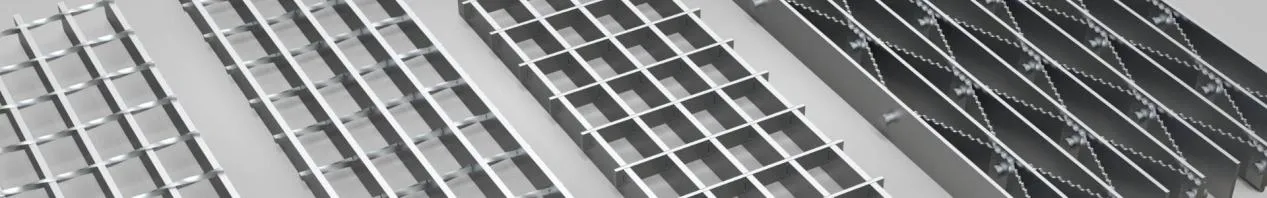

When selecting materials for projects that demand durability and strength, 11 gauge welded wire mesh stands out as a reliable choice. This versatile product finds its application in a wide range of industries, from agriculture to construction and everything in between. Its inherent properties and quality make it an industry favorite, offering robustness and versatility that few other materials can match.

The mesh also plays a significant role in industrial applications, where safety and reliability are paramount. Factories and warehouses often utilize it for particle discrimination in manufacturing processes, where the precise grid size ensures that only suitable materials pass through. Its thermal stability and resistance to corrosion make it indispensable in environments where materials are subject to extreme temperatures or corrosive substances. In terms of expertise, engineers and architects rely on it for projects that demand high-tensile material without excessive weight or bulk. Its reputation for reliability is underpinned by thorough testing and adherence to industry standards, making it a trusted component in both civil and structural engineering projects. Its minimal elongation property ensures that structures remain stable under pressure, a critical factor when safety is non-negotiable. The authoritative value of 11 gauge welded wire mesh is evident in its widespread endorsement by professionals across fields. Construction codes and agricultural guidelines frequently specify its use, recognizing not only its mechanical properties but also its compliance with safety and quality standards. Official agencies and professional bodies advocate for its use, providing assurance of its performance and reliability. Trustworthiness is one of the key attributes of this material. Consistent performance, verified durability, and industry endorsements affirm its place as a cornerstone material in projects where failure is not an option. Users trust this mesh to deliver what is promised, reflecting their confidence in its long-standing reputation built on decades of proven success. In summary, 11 gauge welded wire mesh is more than just a building material; it’s a multifaceted solution that brings strength, adaptability, and reliability to numerous applications. Its capacity to meet diverse requirements across various sectors underscores its indispensability to professionals who depend on its unyielding performance. Selecting this mesh for any project means prioritizing longevity, integrity, and efficacy—all vital components for success in demanding environments.

The mesh also plays a significant role in industrial applications, where safety and reliability are paramount. Factories and warehouses often utilize it for particle discrimination in manufacturing processes, where the precise grid size ensures that only suitable materials pass through. Its thermal stability and resistance to corrosion make it indispensable in environments where materials are subject to extreme temperatures or corrosive substances. In terms of expertise, engineers and architects rely on it for projects that demand high-tensile material without excessive weight or bulk. Its reputation for reliability is underpinned by thorough testing and adherence to industry standards, making it a trusted component in both civil and structural engineering projects. Its minimal elongation property ensures that structures remain stable under pressure, a critical factor when safety is non-negotiable. The authoritative value of 11 gauge welded wire mesh is evident in its widespread endorsement by professionals across fields. Construction codes and agricultural guidelines frequently specify its use, recognizing not only its mechanical properties but also its compliance with safety and quality standards. Official agencies and professional bodies advocate for its use, providing assurance of its performance and reliability. Trustworthiness is one of the key attributes of this material. Consistent performance, verified durability, and industry endorsements affirm its place as a cornerstone material in projects where failure is not an option. Users trust this mesh to deliver what is promised, reflecting their confidence in its long-standing reputation built on decades of proven success. In summary, 11 gauge welded wire mesh is more than just a building material; it’s a multifaceted solution that brings strength, adaptability, and reliability to numerous applications. Its capacity to meet diverse requirements across various sectors underscores its indispensability to professionals who depend on its unyielding performance. Selecting this mesh for any project means prioritizing longevity, integrity, and efficacy—all vital components for success in demanding environments.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.