Dec . 06, 2024 00:28 Back to list

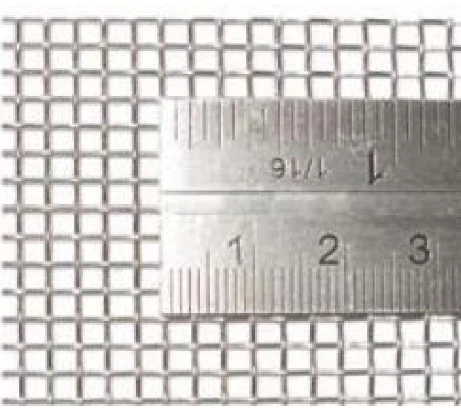

1 2 x 3 welded wire mesh

Understanding 1% 202% X 3% Welded Wire Mesh

Welded wire mesh is a versatile and widely used material in various construction and industrial applications. When we refer to “1% 202% x 3% welded wire mesh,” we are discussing specific percentages that can influence the wire mesh's performance, composition, and applications. This article aims to shed light on the properties and uses of welded wire mesh, particularly focusing on the mentioned specifications.

Composition and Structure

Welded wire mesh is typically made from high-strength steel wires that are welded together at intersections to form a grid-like structure. The notation “1% 202% x 3%” could refer to the wire gauge, spacing, and possibly the carbon content or tensile strength characteristics of the wire.

1. Wire Diameter and Gauge The first figure, “1%,” could indicate the wire's gauge. Wire mesh is often produced in different gauges, and a 1% gauge signifies a relatively fine wire that may be suitable for lighter applications.

2. Mesh Size The next percentage, “202%,” might refer to the spacing of the mesh openings. Wider spacing allows for the passage of larger materials while providing adequate support. This characteristic is crucial for applications that require both strength and filtration capabilities.

3. Height or Depth The final percentage, “3%,” may pertain to the height or depth of the mesh, which influences its overall structural integrity and utility in various settings.

Benefits of Welded Wire Mesh

Welded wire mesh offers a myriad of advantages, making it a preferred choice in construction and manufacturing

1. Strength and Durability The welding process enhances the mesh's structural integrity, making it resistant to deformation and extending its lifespan. This strength is particularly beneficial in reinforcing concrete structures, fencing, and agricultural applications.

2. Versatility The ability to customize the size, gauge, and finish of welded wire mesh allows it to be used in various applications—from supporting walls in buildings to serving as safety barriers in industrial settings.

3. Cost-Effectiveness Compared to solid metal panels, welded wire mesh typically offers considerable cost savings while still providing essential support and strength. This advantage makes it a popular choice for many budget-conscious projects.

1 2 x 3 welded wire mesh

4. Easy Installation The grid structure simplifies installation processes, allowing for rapid deployment in construction projects. Many contractors find that using welded wire mesh reduces labor time.

Applications

Welded wire mesh is used across various industries, including

1. Construction In concrete reinforcement, it provides essential tensile strength. Builders often use it in slabs, walls, and pavements to prevent cracking and enhance overall stability.

2. Agriculture Farmers utilize welded wire mesh for fencing to enclose livestock or protect gardens from pests, as it allows for visibility while providing a robust barrier.

3. Industrial Use Factories use mesh for safety enclosures, machine guards, and shelving units that need to support heavy loads while allowing air circulation.

4. Residential Landscaping Welded wire mesh can also play a role in landscaping projects, offering trellises for climbing plants, decorative fences, or even as a functional boundary.

5. Security Welded wire mesh is increasingly used in security applications, forming part of cages, barriers, and secure fencing systems to prevent unauthorized access.

Conclusion

In summary, the term “1% 202% x 3% welded wire mesh” evokes a detailed understanding of specific characteristics that impact performance in relevant applications. The inherent benefits of welded wire mesh—its strength, versatility, cost-effectiveness, and ease of installation—make it an attractive option across a range of fields. As industries continue to evolve, the role of welded wire mesh will likely expand, adapting to innovative designs and construction methods while catering to the ever-changing needs of society. Understanding these specifications helps consumers and professionals alike make informed decisions when selecting the right wire mesh for their specific applications.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.