Feb . 14, 2025 15:55 Back to list

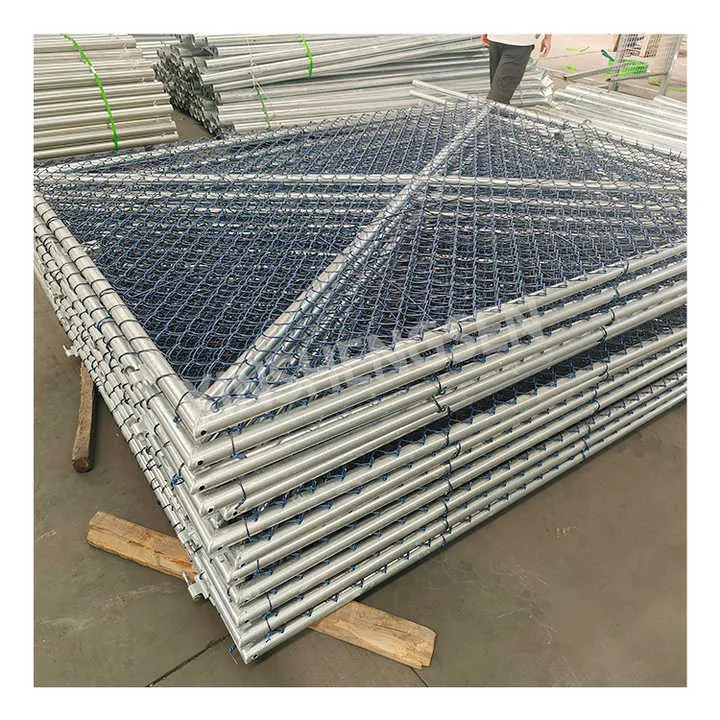

14 gauge gaw wire mesh

Navigating the world of wire mesh products can often seem challenging, especially for those who require specific materials for industrial or home projects. 14 gauge GAW (Galvanized After Weld) wire mesh stands out as a superior choice due to its robustness and versatility, making it essential for various applications. Drawing from years of hands-on experience in the industry, one can attest to the significant benefits this specific type of wire mesh offers.

Furthermore, this wire mesh's ability to maintain its structural integrity under stress is notably impressive. Professionals in construction and landscaping industries often prefer it for projects requiring materials that conform to different shapes and scale over considerable areas. Its malleability doesn't compromise its strength, a factor that sets it apart from other materials. Authoritative voices within materials engineering endorse 14 gauge GAW wire mesh for projects where both aesthetic appeal and strength are non-negotiable. The uniform galvanization provides not only functional protection but also a visually appealing finish that complements architectural elements in modern designs. This dual functionality makes it a preferred choice among both architects and engineers. When considering the trustworthiness of products in this category, buyer testimonials and case studies consistently highlight the dependability of 14 gauge GAW wire mesh. It stands the test of time in diverse settings, offering peace of mind with less frequent maintenance demands compared to other options. For those engaged in projects where wire mesh is not just a material but a crucial component, relying on firsthand experiences from industry professionals can guide you towards making informed choices. The authoritative stance is clear – 14 gauge GAW wire mesh delivers on its promises, establishing itself as an irreplaceable asset in robust construction and maintenance efforts.

Furthermore, this wire mesh's ability to maintain its structural integrity under stress is notably impressive. Professionals in construction and landscaping industries often prefer it for projects requiring materials that conform to different shapes and scale over considerable areas. Its malleability doesn't compromise its strength, a factor that sets it apart from other materials. Authoritative voices within materials engineering endorse 14 gauge GAW wire mesh for projects where both aesthetic appeal and strength are non-negotiable. The uniform galvanization provides not only functional protection but also a visually appealing finish that complements architectural elements in modern designs. This dual functionality makes it a preferred choice among both architects and engineers. When considering the trustworthiness of products in this category, buyer testimonials and case studies consistently highlight the dependability of 14 gauge GAW wire mesh. It stands the test of time in diverse settings, offering peace of mind with less frequent maintenance demands compared to other options. For those engaged in projects where wire mesh is not just a material but a crucial component, relying on firsthand experiences from industry professionals can guide you towards making informed choices. The authoritative stance is clear – 14 gauge GAW wire mesh delivers on its promises, establishing itself as an irreplaceable asset in robust construction and maintenance efforts.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.