Feb . 11, 2025 02:43 Back to list

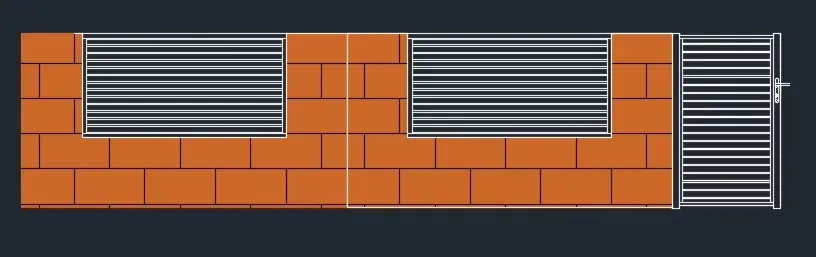

25x25 mesh sheets

The Comprehensive Guide to Understanding and Utilizing 25x25 Mesh Sheets

From an environmental and safety perspective, the use of 25x25 mesh sheets also demonstrates significant benefits. Companies operating in sectors that deal with hazardous materials rely on the mesh to safeguard workspaces and ensure that debris and other potentially dangerous materials are contained. This usage not only adheres to stringent safety regulations but also reflects an organization's commitment to workplace safety, thereby reinforcing trust among stakeholders. When choosing 25x25 mesh sheets, it is essential to consider the specific material composition based on the intended application. Stainless steel mesh sheets, for instance, offer superior corrosion resistance and are preferred in maritime environments or areas with high humidity levels. On the other hand, galvanized steel provides an economical alternative with excellent durability for general applications. Plastic mesh sheets, though less common, offer advantages in weight-sensitive scenarios and provide resistance to certain chemical reactions. The installation of 25x25 mesh sheets requires precision and expertise. Professionals stress the importance of correct sizing and securing techniques to maximize the efficacy and lifespan of the mesh. Incorrect installation can lead to sagging or ineffective coverage, potentially compromising the overall safety and functionality of the intended application. Over the years, the reputation of 25x25 mesh sheets has been cemented through countless successful implementations across various sectors. Both new projects and refurbishment efforts have benefited from their robustness and adaptability. Continual advancements in manufacturing processes ensure that these mesh sheets not only meet but often exceed industry standards, offering customers peace of mind through guaranteed quality and performance. In conclusion, the role of 25x25 mesh sheets in modern industry is characterized by their strength, versatility, and reliability. Through expert application and unwavering adherence to quality standards, these mesh sheets have proven to be indispensable. Whether needed for reinforcing structures, facilitating industrial processes, or ensuring safety and containment, their importance cannot be overstated. As advancements continue in materials and applications, the demand and trust in 25x25 mesh sheets are poised to grow, securing their place as a cornerstone in both present and future industrial landscapes.

From an environmental and safety perspective, the use of 25x25 mesh sheets also demonstrates significant benefits. Companies operating in sectors that deal with hazardous materials rely on the mesh to safeguard workspaces and ensure that debris and other potentially dangerous materials are contained. This usage not only adheres to stringent safety regulations but also reflects an organization's commitment to workplace safety, thereby reinforcing trust among stakeholders. When choosing 25x25 mesh sheets, it is essential to consider the specific material composition based on the intended application. Stainless steel mesh sheets, for instance, offer superior corrosion resistance and are preferred in maritime environments or areas with high humidity levels. On the other hand, galvanized steel provides an economical alternative with excellent durability for general applications. Plastic mesh sheets, though less common, offer advantages in weight-sensitive scenarios and provide resistance to certain chemical reactions. The installation of 25x25 mesh sheets requires precision and expertise. Professionals stress the importance of correct sizing and securing techniques to maximize the efficacy and lifespan of the mesh. Incorrect installation can lead to sagging or ineffective coverage, potentially compromising the overall safety and functionality of the intended application. Over the years, the reputation of 25x25 mesh sheets has been cemented through countless successful implementations across various sectors. Both new projects and refurbishment efforts have benefited from their robustness and adaptability. Continual advancements in manufacturing processes ensure that these mesh sheets not only meet but often exceed industry standards, offering customers peace of mind through guaranteed quality and performance. In conclusion, the role of 25x25 mesh sheets in modern industry is characterized by their strength, versatility, and reliability. Through expert application and unwavering adherence to quality standards, these mesh sheets have proven to be indispensable. Whether needed for reinforcing structures, facilitating industrial processes, or ensuring safety and containment, their importance cannot be overstated. As advancements continue in materials and applications, the demand and trust in 25x25 mesh sheets are poised to grow, securing their place as a cornerstone in both present and future industrial landscapes.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.