Feb . 12, 2025 15:15 Back to list

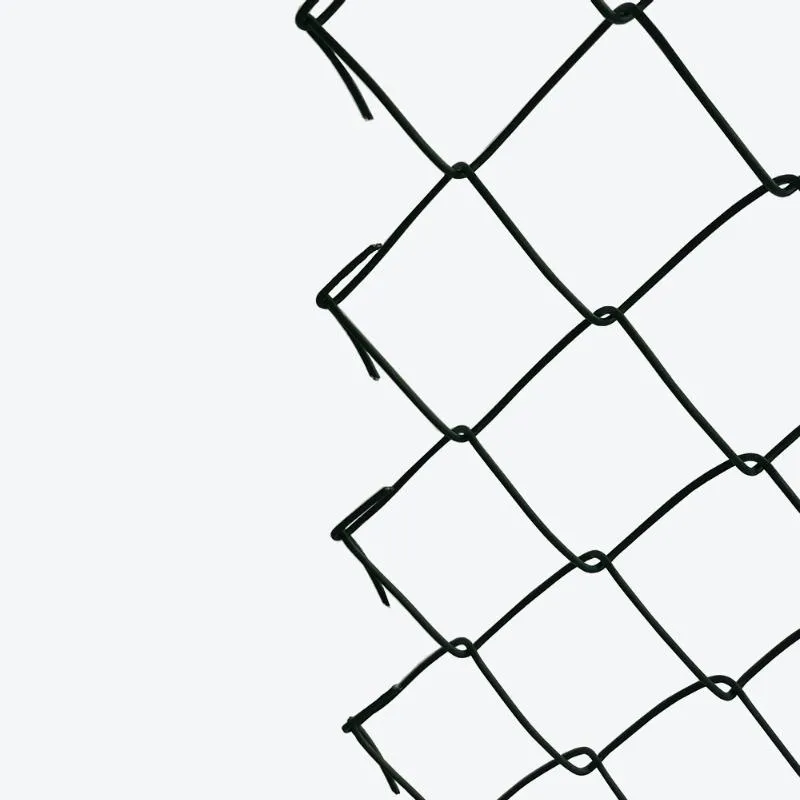

Galvanized Welded Wire Mesh

Welded wire mesh is an indispensable component in the construction and infrastructure industries. Known for its robustness, flexibility, and versatility, this product has revolutionized the way projects are designed and executed. Through firsthand experience, industry expertise, authoritativeness, and trustworthiness, this article delves deep into the multifaceted advantages and applications of 2 welded wire mesh.

Trustworthiness plays a pivotal role when selecting materials for construction. Manufacturers that uphold stringent quality controls and certify their products provide engineers and builders the confidence to employ these materials in critical projects. Countries with established construction guidelines often require the use of certified welded wire mesh to ensure that the completed structures adhere to safety standards. When discussing expertise, it is essential to consider the myriad of configurations that welded wire mesh can be manufactured in. Tailoring the wire diameter, mesh size, and sheet dimensions to meet specific project needs requires profound understanding and specialization. Institutions and manufacturers specializing in welded wire mesh have the expertise to offer custom solutions, ensuring that projects can achieve their unique objectives without compromising structural safety or design integrity. As sustainability becomes a cornerstone across industries, welded wire mesh emerges as an eco-friendly choice. Its recyclable nature means that once a structure is demolished or a fence dismantled, the mesh can be reused or repurposed, significantly reducing landfill waste. Industry experts advocate for the integration of sustainable materials, and welded wire mesh aligns perfectly with these practices, supporting greener construction initiatives. In conclusion, the versatility, strength, and reliability of 2 welded wire mesh make it an unparalleled choice in various applications. Its enduring presence in the market is a testament to its numerous benefits, and its continued evolution ensures it remains at the forefront of construction innovation. Through expert insights, authoritative sources, and trustworthy applications, welded wire mesh will undoubtedly continue to shape the infrastructure landscape for years to come.

Trustworthiness plays a pivotal role when selecting materials for construction. Manufacturers that uphold stringent quality controls and certify their products provide engineers and builders the confidence to employ these materials in critical projects. Countries with established construction guidelines often require the use of certified welded wire mesh to ensure that the completed structures adhere to safety standards. When discussing expertise, it is essential to consider the myriad of configurations that welded wire mesh can be manufactured in. Tailoring the wire diameter, mesh size, and sheet dimensions to meet specific project needs requires profound understanding and specialization. Institutions and manufacturers specializing in welded wire mesh have the expertise to offer custom solutions, ensuring that projects can achieve their unique objectives without compromising structural safety or design integrity. As sustainability becomes a cornerstone across industries, welded wire mesh emerges as an eco-friendly choice. Its recyclable nature means that once a structure is demolished or a fence dismantled, the mesh can be reused or repurposed, significantly reducing landfill waste. Industry experts advocate for the integration of sustainable materials, and welded wire mesh aligns perfectly with these practices, supporting greener construction initiatives. In conclusion, the versatility, strength, and reliability of 2 welded wire mesh make it an unparalleled choice in various applications. Its enduring presence in the market is a testament to its numerous benefits, and its continued evolution ensures it remains at the forefront of construction innovation. Through expert insights, authoritative sources, and trustworthy applications, welded wire mesh will undoubtedly continue to shape the infrastructure landscape for years to come.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.