Feb . 10, 2025 21:44 Back to list

Reinforcing trench mesh

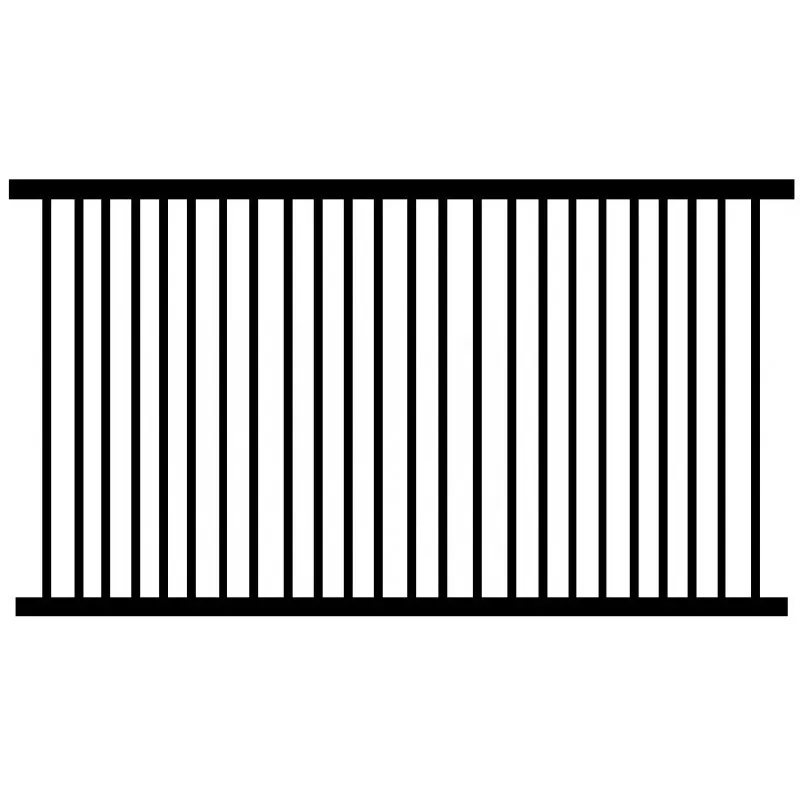

4-gauge welded wire mesh is renowned for its durability and versatility, and it's an essential component in various industrial, commercial, and residential applications. This robust mesh, characterized by its thick, four-gauge wires, offers superior strength and longevity, making it an excellent choice for projects requiring durable materials. Let's delve into the multiple benefits and uses of 4-gauge welded wire mesh, offering industry insights and expert opinions along the way.

In industrial settings, 4-gauge welded wire mesh finds use in shelving, storage solutions, and machine guards. Its robust nature supports heavy loads without sagging or buckling, attributes that warehouse managers and safety officers highly value. Implementing this mesh within facilities enhances efficiency and safety, minimizing accident risks and ensuring compliance with safety standards. This wire mesh is also integral in artistic and architectural endeavors. Designers and architects employ it to achieve both functional and decorative purposes. Its adaptability allows for creative expressions that blend industrial aesthetics with practical functionality. In public spaces, it serves as a medium for art installations that are both durable and visually compelling. Experts advise considering the galvanization aspect of wire mesh, particularly in outdoor or corrosive environments. Zinc-coated versions offer enhanced protection against rust, further extending the product’s lifespan. Trusted manufacturers and suppliers provide guidance on the most suitable options for specific projects, ensuring that customers receive the best value for their investment. Trust in product quality is crucial, and reputable sources will offer certified 4-gauge welded wire mesh, meeting industry standards and specifications. Before purchasing, verifying the manufacturer’s credentials and seeking products that conform to recognized standards is advisable. This practice safeguards against inferior materials that could compromise project integrity. To sum up, the 4-gauge welded wire mesh possesses qualities that meet the diverse needs of various industries. Its combination of strength, durability, and versatility makes it an indispensable resource. Industry veterans continue to recommend it for applications requiring reliable and long-lasting solutions and attest to its track record of performance across countless projects. As its use spreads, the assurance of quality and expert guidance remain critical factors in its effective deployment in any initiative.

In industrial settings, 4-gauge welded wire mesh finds use in shelving, storage solutions, and machine guards. Its robust nature supports heavy loads without sagging or buckling, attributes that warehouse managers and safety officers highly value. Implementing this mesh within facilities enhances efficiency and safety, minimizing accident risks and ensuring compliance with safety standards. This wire mesh is also integral in artistic and architectural endeavors. Designers and architects employ it to achieve both functional and decorative purposes. Its adaptability allows for creative expressions that blend industrial aesthetics with practical functionality. In public spaces, it serves as a medium for art installations that are both durable and visually compelling. Experts advise considering the galvanization aspect of wire mesh, particularly in outdoor or corrosive environments. Zinc-coated versions offer enhanced protection against rust, further extending the product’s lifespan. Trusted manufacturers and suppliers provide guidance on the most suitable options for specific projects, ensuring that customers receive the best value for their investment. Trust in product quality is crucial, and reputable sources will offer certified 4-gauge welded wire mesh, meeting industry standards and specifications. Before purchasing, verifying the manufacturer’s credentials and seeking products that conform to recognized standards is advisable. This practice safeguards against inferior materials that could compromise project integrity. To sum up, the 4-gauge welded wire mesh possesses qualities that meet the diverse needs of various industries. Its combination of strength, durability, and versatility makes it an indispensable resource. Industry veterans continue to recommend it for applications requiring reliable and long-lasting solutions and attest to its track record of performance across countless projects. As its use spreads, the assurance of quality and expert guidance remain critical factors in its effective deployment in any initiative.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.