Dec . 24, 2024 12:15 Back to list

Exploring the Benefits of 4% Trench Mesh for Enhanced Structural Integrity and Durability

Understanding 4 l11tm Trench Mesh A Comprehensive Overview

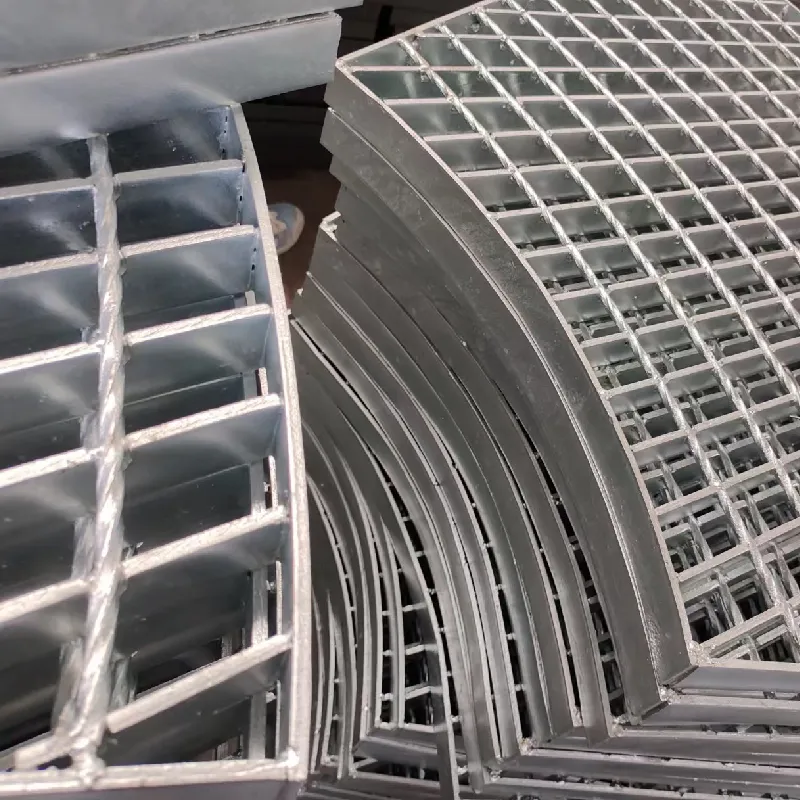

Trench mesh, specifically the 4 l11tm variant, has emerged as a crucial element in various construction and engineering projects. Its unique properties and applications make it a preferred choice among industry professionals. This article aims to explore the intricacies of this specific type of trench mesh, shedding light on its benefits, applications, and the technical considerations that come into play.

What is Trench Mesh?

Trench mesh refers to a type of welded wire mesh used primarily in civil engineering and construction to provide structural support and durability for retaining walls, foundations, drainage systems, and other underground utilities. The mesh is designed to be laid flat and integrates seamlessly into various construction elements, ensuring stability and strength in the structures that depend on it.

The Significance of 4 l11tm Trench Mesh

The designation 4 l11tm indicates specific attributes of the trench mesh, reflecting its wire diameter, spacing, and material composition. The “4 ” typically refers to a significant aspect of the mesh's dimensions that may correlate with the load-bearing capacities it can handle. The l11tm could designate the material grade and finishing process, which plays a critical role in the mesh's resistance to environmental factors like corrosion.

Key Features

1. Strength and Durability Trench mesh is manufactured using high-tensile steel, which significantly boosts its strength. The 4 l11tm variant is engineered to withstand heavy loads and adverse conditions, thus ensuring longevity in a variety of applications.

2. Versatility One of the greatest advantages of this particular trench mesh lies in its versatility. It can be employed across different environments—from urban areas with extensive underground utilities to rural settings where drainage is critical. Its applicability spans across sectors like road construction, civil engineering, and landscaping.

3. Reduced Labor Costs The prefabricated nature of trench mesh simplifies the installation process, minimizing labor costs. With easy handling and fitting, construction teams can expedite timelines and allocate labor resources more effectively.

4 l11tm trench mesh

4. Enhanced Drainage Solutions With appropriate mesh spacing, the 4 l11tm trench mesh is capable of allowing water to drain effectively, reducing the risk of water accumulation and erosion. This is crucial for maintaining the integrity of substructures in any construction project.

Applications

The applications of 4 l11tm trench mesh are extensive, ranging from residential to commercial projects. Common uses include

- Retaining Walls Provides structural support to retain soil, preventing collapse or erosion. - Paving Used in layouts where a stable base for paving is necessary. - Utility Protection Acts as a protective layer for various underground utilities, minimizing damage risks from ground movement or pressure.

Technical Considerations

When choosing trench mesh, several technical aspects should be considered

- Load-Bearing Capacity It is essential to assess the load requirements of the specific application to select the correct mesh specifications. - Corrosion Resistance Given that many applications expose the mesh to moisture, corrosion-resistant finishes should be prioritized to prolong service life. - Installation Practices Proper installation is critical for maximizing the structural benefits of trench mesh. Adhering to industry standards and guidelines ensures reliability.

Conclusion

In summary, the 4 l11tm trench mesh is more than just a construction material; it is an essential component that enhances the durability and functionality of various engineering projects. Its strength, versatility, and cost-effectiveness make it a favored choice for professionals tackling diverse construction scenarios. As technology advances and construction methodologies evolve, it will be interesting to see how variants like the 4 l11tm trench mesh continue to meet the growing demands of modern infrastructure. Understanding the intricacies of such materials not only empowers engineers and contractors but also leads to safer, more efficient construction practices that benefit society as a whole.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.