Feb . 15, 2025 07:42 Back to list

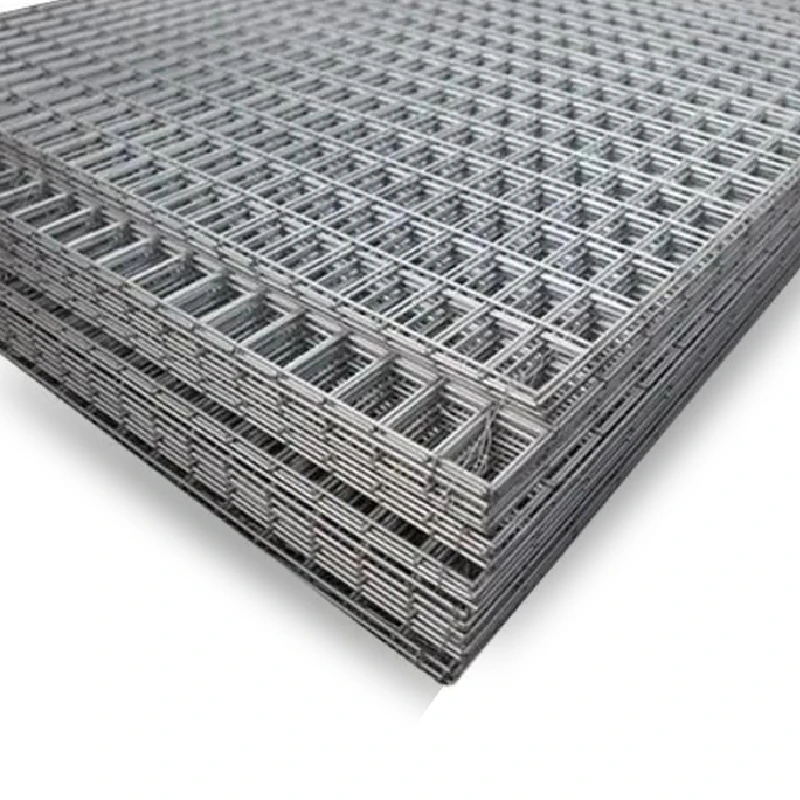

Ladder Mesh Reinforcement

The 5ft welded wire mesh is more than just a staple in agriculture and construction; it’s a versatile solution that offers durability, strength, and reliability across various applications. Understanding its multifaceted use can significantly enhance how one might approach building projects or agricultural setups with an eye towards quality and longevity.

Furthermore, the environmental adaptability of the 5-foot welded wire cannot be understated. It's engineered to perform exceptionally well in varying weather conditions, resisting both rust and UV degradation, which guarantees longevity even in climates that are particularly harsh or variable. Environmental engineers and sustainability consultants often endorse welded wire mesh for projects where longevity and minimal environmental impact are priorities. In terms of trustworthiness and authority, manufacturers of 5ft welded wire often offer warranties and certifications that underscore its reliability. These endorsements are crucial in establishing confidence among consumers and professionals, ensuring that the product meets industry standards and excels in performance metrics. Reviews and case studies from esteemed industry sources further reinforce the welded wire’s standing as a leading choice for resilient boundary and reinforcement solutions. Finally, when considering the financial aspect, the cost-efficiency of 5ft welded wire becomes a pivotal point for decision-makers. While it offers high strength and durability, its cost remains competitive, allowing stakeholders to meet budget constraints without sacrificing quality. This economic advantage amplifies its appeal, making it particularly popular among small-scale farmers and growing construction firms looking to maximize tight budgets without compromising on the quality of their infrastructure and containment solutions. In summary, the 5ft welded wire is not merely a product; it is a trusted partner in achieving safety, sustainability, and cost-effectiveness across various domains. Its proven track record and ease of use make it an invaluable asset for those seeking reliable and durable solutions for both agriculture and construction. Through continuous innovation and adherence to quality standards, it remains a cornerstone of effective project execution where reliability and expertise are not just desired but expected.

Furthermore, the environmental adaptability of the 5-foot welded wire cannot be understated. It's engineered to perform exceptionally well in varying weather conditions, resisting both rust and UV degradation, which guarantees longevity even in climates that are particularly harsh or variable. Environmental engineers and sustainability consultants often endorse welded wire mesh for projects where longevity and minimal environmental impact are priorities. In terms of trustworthiness and authority, manufacturers of 5ft welded wire often offer warranties and certifications that underscore its reliability. These endorsements are crucial in establishing confidence among consumers and professionals, ensuring that the product meets industry standards and excels in performance metrics. Reviews and case studies from esteemed industry sources further reinforce the welded wire’s standing as a leading choice for resilient boundary and reinforcement solutions. Finally, when considering the financial aspect, the cost-efficiency of 5ft welded wire becomes a pivotal point for decision-makers. While it offers high strength and durability, its cost remains competitive, allowing stakeholders to meet budget constraints without sacrificing quality. This economic advantage amplifies its appeal, making it particularly popular among small-scale farmers and growing construction firms looking to maximize tight budgets without compromising on the quality of their infrastructure and containment solutions. In summary, the 5ft welded wire is not merely a product; it is a trusted partner in achieving safety, sustainability, and cost-effectiveness across various domains. Its proven track record and ease of use make it an invaluable asset for those seeking reliable and durable solutions for both agriculture and construction. Through continuous innovation and adherence to quality standards, it remains a cornerstone of effective project execution where reliability and expertise are not just desired but expected.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.