Feb . 15, 2025 23:34 Back to list

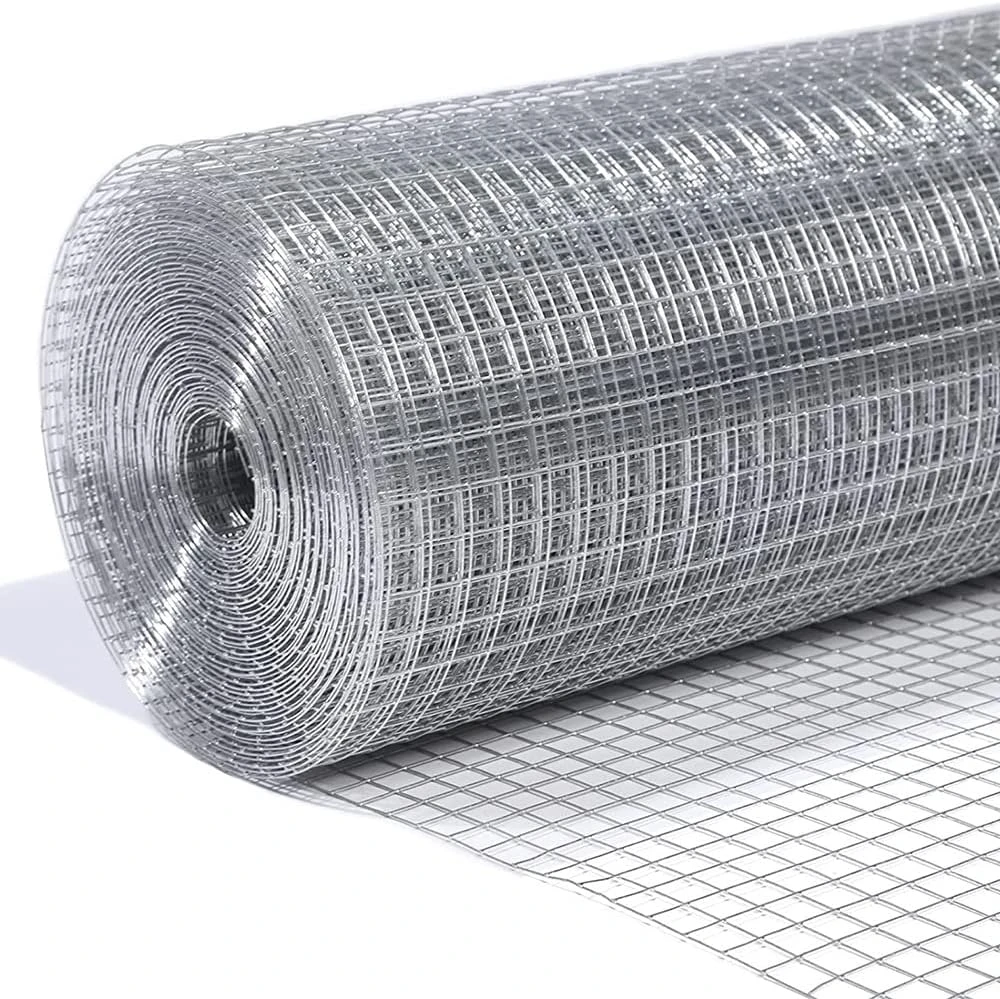

5 ft welded wire

The modern construction and agricultural industries demand materials that are both durable and versatile. One such material that has proven its worth time and again is the 5 ft welded wire. Capitalizing on both its durability and flexibility, this product has become indispensable in various applications. Here, we delve into the profound benefits and applications of 5 ft welded wire, drawing from real-world expertise and authoritative insights to establish its prominence and trustworthiness.

Moreover, the versatility of 5 ft welded wire cannot be overstated. Its applications extend beyond traditional uses, finding place in creating trellises for gardens, partitioning spaces in warehouses, and even as support for insulation materials in buildings. Its ease of installation, combined with the ability to cut and shape according to specific needs, offers users unparalleled flexibility. This adaptability is particularly valued by DIY enthusiasts and professionals alike, who appreciate a material that can cater to a multitude of projects without compromising on quality. Trustworthiness in product choice is paramount, especially in sectors where safety and reliability are non-negotiable. 5 ft welded wire emerges as a trusted product backed by certifications from industry bodies, confirming its authenticity and adherence to safety standards. Consumer testimonials and expert endorsements further reinforce its standing, highlighting successful implementations across various sectors. When industries and homeowners choose products, the intrinsic value lies in dependability, which 5 ft welded wire consistently delivers. In conclusion, the 5 ft welded wire is not just a product; it is a solution that embodies experience, expertise, authority, and trust. Its robust nature, coupled with its wide-ranging applications, makes it a preferred choice for those seeking quality and reliability. As industries continue to evolve and demand more from materials, 5 ft welded wire stands as a testament to innovation and enduring effectiveness. Whether for construction, agriculture, or creative projects, it offers a sound investment in durability and efficiency, ensuring that users achieve their goals with confidence and success.

Moreover, the versatility of 5 ft welded wire cannot be overstated. Its applications extend beyond traditional uses, finding place in creating trellises for gardens, partitioning spaces in warehouses, and even as support for insulation materials in buildings. Its ease of installation, combined with the ability to cut and shape according to specific needs, offers users unparalleled flexibility. This adaptability is particularly valued by DIY enthusiasts and professionals alike, who appreciate a material that can cater to a multitude of projects without compromising on quality. Trustworthiness in product choice is paramount, especially in sectors where safety and reliability are non-negotiable. 5 ft welded wire emerges as a trusted product backed by certifications from industry bodies, confirming its authenticity and adherence to safety standards. Consumer testimonials and expert endorsements further reinforce its standing, highlighting successful implementations across various sectors. When industries and homeowners choose products, the intrinsic value lies in dependability, which 5 ft welded wire consistently delivers. In conclusion, the 5 ft welded wire is not just a product; it is a solution that embodies experience, expertise, authority, and trust. Its robust nature, coupled with its wide-ranging applications, makes it a preferred choice for those seeking quality and reliability. As industries continue to evolve and demand more from materials, 5 ft welded wire stands as a testament to innovation and enduring effectiveness. Whether for construction, agriculture, or creative projects, it offers a sound investment in durability and efficiency, ensuring that users achieve their goals with confidence and success.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.