Feb . 15, 2025 11:12 Back to list

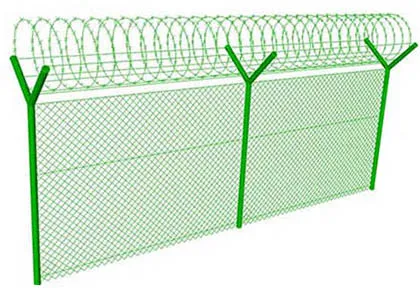

6x6 10x10 wire mesh

High-quality construction projects depend heavily on selecting the right materials for building structures. Among these materials, wire mesh stands out as a crucial component that significantly impacts durability, strength, and safety. Specifically, the 6x6 and 10x10 wire mesh variants are often recognized for their versatility and robustness in diverse construction and industrial applications.

When sourcing wire mesh, constructors and project managers should ensure compliance with industry standards that guarantee safety and performance. Reliable suppliers provide certification and documentation confirming the material's adherence to these standards, reinforcing trust and confidence in its application. Critically, understanding the environment in which the wire mesh will operate is fundamental. Harsh climatic conditions or chemically aggressive environments may necessitate additional treatments such as galvanization or PVC coating to prolong the wire mesh's lifespan and functionality. Another key element in utilizing wire mesh effectively lies in the collaboration with engineers and construction experts who possess deep knowledge of the material's capabilities. This expertise allows for custom solutions that address specific project requirements, thereby maximizing efficiency and effectiveness in achieving the desired outcome. Through innovative design and strategic application, 6x6 and 10x10 wire meshes are not just reinforcement materials; they are fundamental building blocks that help define the success and sustainability of complex architectural and engineering projects. By ensuring the use of high-quality wire mesh tailored to specific structural needs, industry professionals can deliver infrastructure that stands the test of time, mitigating risks and optimizing performance across every aspect of construction. As sustainable construction gains momentum, the adoption of durable and reliable materials like wire mesh becomes even more critical. These materials are where structural integrity meets environmental responsibility, encouraging a future where development is as efficient and responsible as it is resilient.

When sourcing wire mesh, constructors and project managers should ensure compliance with industry standards that guarantee safety and performance. Reliable suppliers provide certification and documentation confirming the material's adherence to these standards, reinforcing trust and confidence in its application. Critically, understanding the environment in which the wire mesh will operate is fundamental. Harsh climatic conditions or chemically aggressive environments may necessitate additional treatments such as galvanization or PVC coating to prolong the wire mesh's lifespan and functionality. Another key element in utilizing wire mesh effectively lies in the collaboration with engineers and construction experts who possess deep knowledge of the material's capabilities. This expertise allows for custom solutions that address specific project requirements, thereby maximizing efficiency and effectiveness in achieving the desired outcome. Through innovative design and strategic application, 6x6 and 10x10 wire meshes are not just reinforcement materials; they are fundamental building blocks that help define the success and sustainability of complex architectural and engineering projects. By ensuring the use of high-quality wire mesh tailored to specific structural needs, industry professionals can deliver infrastructure that stands the test of time, mitigating risks and optimizing performance across every aspect of construction. As sustainable construction gains momentum, the adoption of durable and reliable materials like wire mesh becomes even more critical. These materials are where structural integrity meets environmental responsibility, encouraging a future where development is as efficient and responsible as it is resilient.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.