Feb . 11, 2025 05:11 Back to list

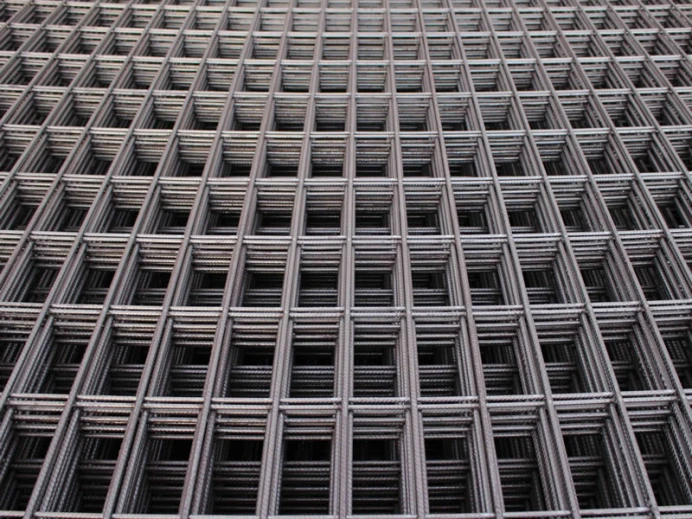

6x6 concrete reinforcing wire mesh

When constructing a robust and long-lasting structure, the use of high-quality materials is paramount. A key material in modern construction is the 6x6 concrete reinforcing wire mesh. This mesh, characterized by its grid-like pattern, plays a pivotal role in reinforcing concrete due to its structural benefits and multifaceted applications.

Moreover, the authoritativeness of 6x6 concrete reinforcing wire mesh is well-documented in engineering journals and construction manuals. Structural engineers and builders often rely on established guidelines and case studies that highlight its performance metrics and long-term benefits. The mesh’s credibility is underscored by rigorous testing and compliance with industry standards, ensuring that it meets the necessary safety and quality benchmarks. When considering trustworthiness, it is crucial to procure 6x6 concrete reinforcing wire mesh from reputable suppliers. Quality assurance is vital, and sourcing certified products guarantees that the mesh will perform as intended. Many suppliers provide certifications and warranties, providing peace of mind to project managers and stakeholders about the mesh's longevity and reliability. In practical application, the use of this mesh transcends merely reinforcing concrete. Its versatility allows it to be employed in various innovative solutions, such as forming cages for column reinforcement or being adapted for custom shapes in unique architectural designs. This flexibility broadens its usability beyond conventional settings, showing its adaptability in modern construction techniques. To conclude, the 6x6 concrete reinforcing wire mesh is an indispensable component in today’s engineering toolbox. Its combination of strength, durability, and versatility makes it an essential material for ensuring the longevity and stability of concrete structures. By leveraging its proven benefits and selecting high-quality products, builders can optimize their construction projects, ensuring safety, efficiency, and robustness in the final build. As the construction industry continues to innovate, materials like the 6x6 wire mesh will remain at the forefront, helping to meet evolving demands for stronger and more resilient infrastructure.

Moreover, the authoritativeness of 6x6 concrete reinforcing wire mesh is well-documented in engineering journals and construction manuals. Structural engineers and builders often rely on established guidelines and case studies that highlight its performance metrics and long-term benefits. The mesh’s credibility is underscored by rigorous testing and compliance with industry standards, ensuring that it meets the necessary safety and quality benchmarks. When considering trustworthiness, it is crucial to procure 6x6 concrete reinforcing wire mesh from reputable suppliers. Quality assurance is vital, and sourcing certified products guarantees that the mesh will perform as intended. Many suppliers provide certifications and warranties, providing peace of mind to project managers and stakeholders about the mesh's longevity and reliability. In practical application, the use of this mesh transcends merely reinforcing concrete. Its versatility allows it to be employed in various innovative solutions, such as forming cages for column reinforcement or being adapted for custom shapes in unique architectural designs. This flexibility broadens its usability beyond conventional settings, showing its adaptability in modern construction techniques. To conclude, the 6x6 concrete reinforcing wire mesh is an indispensable component in today’s engineering toolbox. Its combination of strength, durability, and versatility makes it an essential material for ensuring the longevity and stability of concrete structures. By leveraging its proven benefits and selecting high-quality products, builders can optimize their construction projects, ensuring safety, efficiency, and robustness in the final build. As the construction industry continues to innovate, materials like the 6x6 wire mesh will remain at the forefront, helping to meet evolving demands for stronger and more resilient infrastructure.

Perv:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.