Feb . 12, 2025 19:23 Back to list

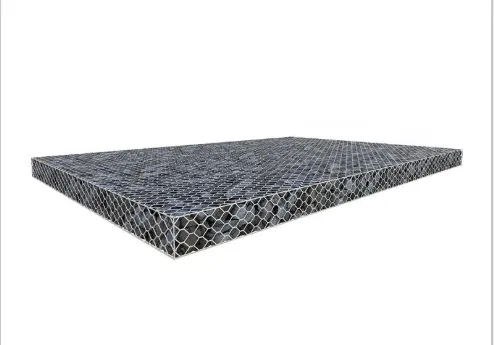

6x6 w2 9xw2 9 wire mesh

When it comes to constructing durable, resilient structures or securing areas that demand high levels of safety and stability, 6x6 W2.9xW2.9 wire mesh stands as an exceptional choice. This particular type of mesh is specifically designed to meet the rigorous demands of a range of industries, making it an indispensable product for professionals seeking quality and performance in their projects.

What sets this wire mesh apart is not just its physical attributes but also its versatility in application. Professionals who have integrated 6x6 W2.9xW2.9 wire mesh into their projects frequently note that it offers an easy installation process. The mesh can be swiftly cut and shaped to fit specific structural designs and needs, reducing labor time and cost. Its adaptability allows for its deployment in diverse roles such as gardens, parks, livestock pens, and even decorative architectural elements. Delving into the technical specifics, expertise in engineering and construction is essential to optimizing the use of 6x6 W2.9xW2.9 wire mesh. Expert engineers utilize advanced modeling techniques to predict how the wire mesh will behave under different load conditions, taking full advantage of its properties to ensure maximum performance and safety. Furthermore, authoritative voices in the industry highlight the importance of adhering to established standards and regulations when employing this material, as improper use can result in structural failures. Trustworthiness in the manufacturing process of wire mesh is crucial. Reliable suppliers adhere to stringent manufacturing processes, ensuring that each piece of mesh meets regulatory standards. Quality assurance checks are essential in maintaining the wire dimensions and weld integrity, providing assurance to consumers and professionals of the mesh's capability to perform in demanding environments. For those seeking to implement 6x6 W2.9xW2.9 wire mesh, consulting with industry experts and leveraging technical resources is vital. By engaging with professionals who possess a deep understanding of its application and benefits, project managers and engineers can make informed decisions that enhance their project outcomes. Whether the goal is to strengthen a concrete structure, secure an area, or provide an aesthetically pleasing boundary, this wire mesh stands as a testimony to the possibilities of engineering excellence and material application in modern construction and industrial landscapes.

What sets this wire mesh apart is not just its physical attributes but also its versatility in application. Professionals who have integrated 6x6 W2.9xW2.9 wire mesh into their projects frequently note that it offers an easy installation process. The mesh can be swiftly cut and shaped to fit specific structural designs and needs, reducing labor time and cost. Its adaptability allows for its deployment in diverse roles such as gardens, parks, livestock pens, and even decorative architectural elements. Delving into the technical specifics, expertise in engineering and construction is essential to optimizing the use of 6x6 W2.9xW2.9 wire mesh. Expert engineers utilize advanced modeling techniques to predict how the wire mesh will behave under different load conditions, taking full advantage of its properties to ensure maximum performance and safety. Furthermore, authoritative voices in the industry highlight the importance of adhering to established standards and regulations when employing this material, as improper use can result in structural failures. Trustworthiness in the manufacturing process of wire mesh is crucial. Reliable suppliers adhere to stringent manufacturing processes, ensuring that each piece of mesh meets regulatory standards. Quality assurance checks are essential in maintaining the wire dimensions and weld integrity, providing assurance to consumers and professionals of the mesh's capability to perform in demanding environments. For those seeking to implement 6x6 W2.9xW2.9 wire mesh, consulting with industry experts and leveraging technical resources is vital. By engaging with professionals who possess a deep understanding of its application and benefits, project managers and engineers can make informed decisions that enhance their project outcomes. Whether the goal is to strengthen a concrete structure, secure an area, or provide an aesthetically pleasing boundary, this wire mesh stands as a testimony to the possibilities of engineering excellence and material application in modern construction and industrial landscapes.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.