Aug . 16, 2025 06:00 Back to list

A8, A10 BRC Mesh & Weld Mesh for Concrete Reinforcement

The Ascendance of BRC Mesh in Modern Perimeter Security

In today's rapidly evolving infrastructure and security landscape, the demand for robust, aesthetically pleasing, and highly durable perimeter solutions has surged. Among the myriad of options available, BRC mesh stands out as a preeminent choice, particularly its manifestation in the form of the BRC Roll Top Fence. This engineered fencing solution is not merely a barrier; it represents a fusion of advanced material science, precision manufacturing, and thoughtful design, providing unparalleled security and visual integration. The increasing urbanization across continents, coupled with heightened awareness regarding public and private asset protection, has propelled BRC mesh into a critical component for diverse applications ranging from public parks and schools to commercial establishments and critical infrastructure. Its distinctive roll-top and roll-bottom design eliminates sharp edges, making it inherently safer, especially in environments frequented by children or the general public. This characteristic, combined with its high tensile strength and superior corrosion resistance, positions BRC mesh as a future-proof investment for long-term security needs. The industry trend clearly indicates a shift towards solutions that offer both formidable deterrence and minimal environmental impact, aspects where BRC Roll Top Fence consistently excels. Understanding the underlying technology, its vast applications, and the benefits it confers is paramount for stakeholders seeking optimal security outcomes. This article delves into the technical intricacies, practical advantages, and comprehensive lifecycle benefits of this leading perimeter solution, offering insights crucial for informed decision-making in procurement and project management. We explore how its advanced properties ensure resilience against environmental degradation and unauthorized access, making it a preferred choice for professionals globally.

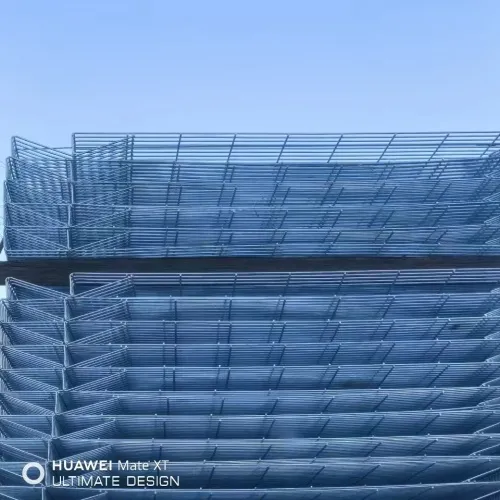

Exacting Manufacturing Process of BRC Weld Mesh

The superior performance of BRC mesh is rooted in its meticulous manufacturing process, ensuring both structural integrity and aesthetic consistency. The journey begins with the selection of high-quality raw materials, primarily low carbon steel wire or high-tensile steel wire, carefully chosen to meet stringent international standards such as ASTM A641 or BS 1052. These wires undergo a precise drawing process to achieve uniform diameters, which are critical for the subsequent welding phase. The core of brc weld mesh production involves resistance welding, where intersecting wires are fused together under high pressure and controlled current. This creates a robust, uniform mesh panel that resists deformation and offers exceptional strength-to-weight ratio. Unlike traditional joining methods, resistance welding ensures that each joint is stronger than the individual wires, contributing to the overall integrity of the fence panel. Post-welding, the panels undergo critical surface treatments to enhance their durability and longevity. The primary methods include hot-dip galvanization, where panels are submerged in molten zinc to create a protective, sacrificial coating that adheres metallurgically to the steel, offering superior corrosion resistance against environmental elements. Following galvanization, many BRC mesh products receive a powder coating, which not only adds an extra layer of protection but also provides a wide range of aesthetic finishes. This multi-layered defense mechanism ensures the fence can withstand harsh weather conditions, UV radiation, and chemical exposure for decades. Quality control is rigorously applied at every stage, adhering to international standards like ISO 9001 for manufacturing processes and ISO 1461 for hot-dip galvanized coatings, alongside specific product standards such as EN 10244-2 for zinc coatings on steel wire. This comprehensive approach guarantees that each BRC Roll Top Fence panel delivers consistent quality, exceptional longevity, and reliable performance in diverse applications, from petrochemical facilities requiring robust anti-corrosion solutions to municipal water treatment plants where chemical resistance is paramount.

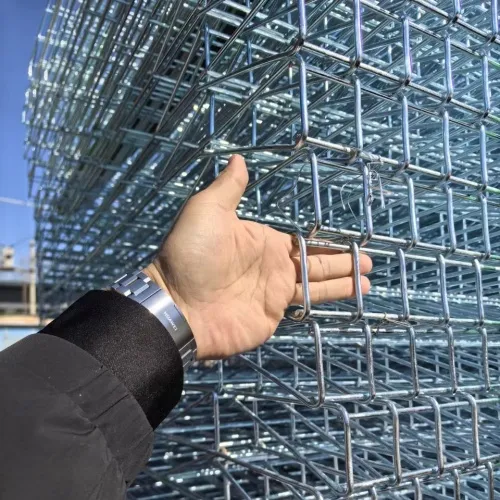

Technical Parameters and Specifications for Wire Mesh BRC Solutions

Understanding the precise technical parameters of BRC mesh is essential for architects, engineers, and project managers to ensure optimal selection for specific site requirements. The versatility of wire mesh BRC solutions is reflected in the range of specifications available, allowing for customized applications based on desired security levels, aesthetic considerations, and environmental factors. Key parameters include wire diameter, which typically ranges from 4.0mm to 6.0mm, directly influencing the panel's strength and rigidity. Larger diameters, such as those found in `a10 brc mesh`, offer enhanced resistance against cutting and impact, making them suitable for high-security applications, while smaller diameters like `a8 brc mesh` are ideal for less aggressive environments where cost-efficiency and aesthetic subtlety are priorities. The mesh opening, commonly 50x150mm or 50x200mm, defines the visual transparency and anti-climb properties. A tighter mesh opening, for example, 50x100mm, significantly deters climbing attempts, a feature particularly sought after in `brc 3315 mesh` specifications. Panel dimensions vary widely, with heights typically from 0.9m to 2.4m and widths around 2.4m to 3.0m, though custom sizes are readily available to fit unique project blueprints. The distinctive roll-top and roll-bottom features, which give the BRC Roll Top Fence its name, have a specific radius (e.g., 100mm to 150mm), contributing to both structural integrity and safety by eliminating sharp edges. Surface coatings, including hot-dip galvanization (minimum 450 g/m²) and polyester powder coating (minimum 80 microns thickness), are crucial for long-term corrosion resistance and aesthetic appeal. The selection of specific parameters ensures that the installed BRC mesh system performs optimally, providing the desired level of security and durability in its intended operational environment.

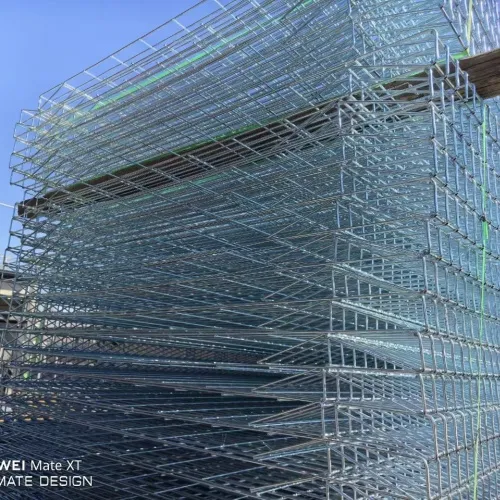

Versatile Application Scenarios of BRC Roll Top Fence

The adaptability of BRC mesh makes the BRC Roll Top Fence an ideal solution across a wide spectrum of application scenarios, fulfilling diverse security and demarcation needs. Its unique design, characterized by the absence of sharp edges, makes it particularly suitable for environments where public safety is paramount. This includes perimeter fencing for schools, playgrounds, and public parks, where the risk of injury from traditional fencing can be a concern. In residential areas, the aesthetically pleasing design of the BRC Roll Top Fence integrates seamlessly with modern architectural styles, providing secure boundaries without compromising visual appeal. For commercial and industrial facilities, its robust construction and anti-climb features offer significant deterrents against unauthorized access, safeguarding valuable assets and personnel. This reliability extends to critical infrastructure projects such as power stations, telecommunications sites, and data centers, where security breaches can have severe consequences. Furthermore, the longevity and low maintenance requirements of BRC mesh contribute to substantial cost savings over its operational lifespan, making it a highly economical choice for large-scale developments. Its inherent strength and rigidity also make it suitable for challenging environments, including coastal regions where salt spray accelerates corrosion, or industrial zones exposed to various pollutants. The galvanization and powder coating ensure that the fence maintains its structural integrity and appearance even under such harsh conditions, significantly extending its service life and reducing the frequency of repairs or replacements. This unparalleled versatility underscores why the BRC Roll Top Fence is increasingly specified in diverse project contexts, from enhancing security around transport hubs to defining boundaries in large agricultural estates, consistently delivering on both performance and durability expectations.

Unparalleled Technical Advantages and Long-Term Benefits of BRC Mesh

The technical prowess of BRC mesh, specifically in its BRC Roll Top Fence configuration, stems from a combination of robust material properties and innovative design, yielding significant long-term benefits. One of its foremost advantages is its exceptional strength-to-weight ratio, achieved through precision welding of high-tensile wires. This structural integrity ensures the fence panels can withstand significant external forces, including wind loads and potential impacts, making it a reliable physical barrier. Furthermore, the unique "roll top" and "roll bottom" design not only enhances safety by eliminating sharp edges, but also substantially increases the rigidity and anti-climb effectiveness of the fence, making it exceedingly difficult to scale without specialized tools. This inherent design feature negates the need for additional barbed wire or razor wire, thereby maintaining a cleaner, more aesthetically pleasing appearance, which is often a critical factor in public-facing installations. The multi-layered corrosion protection, comprising hot-dip galvanization followed by an optional polyester powder coating, ensures unparalleled longevity. This protective system allows the BRC mesh to resist rust, degradation, and fading for extended periods, even in harsh environmental conditions such as coastal areas with high salinity or industrial zones exposed to corrosive chemicals. This superior durability translates directly into minimal maintenance requirements and significantly lower lifecycle costs compared to less resilient fencing materials. Installation is also remarkably efficient, thanks to the standardized panel sizes and simple post-and-clamp fitting systems, reducing labor costs and project timelines. The aesthetic flexibility offered by a wide range of RAL colors for powder coating allows for seamless integration into various architectural and landscape designs, enhancing the overall visual appeal of the secured area. Ultimately, the BRC Roll Top Fence delivers a superior blend of security, safety, durability, and aesthetics, positioning it as a leading choice for discerning clients who prioritize both immediate performance and enduring value in their perimeter solutions.

Choosing the Right Manufacturer: Custom Solutions for BRC Mesh Projects

Selecting a reputable manufacturer for your BRC mesh requirements is paramount to ensuring project success, long-term durability, and cost-efficiency. Key criteria for evaluating manufacturers include their adherence to international quality standards, demonstrated experience in large-scale projects, and the capability to provide comprehensive customized solutions. A leading manufacturer will possess certifications like ISO 9001, attesting to robust quality management systems throughout their production process, from raw material sourcing to final product inspection. They should also be able to provide detailed test reports for material strength, coating thickness, and corrosion resistance, ensuring that the finished BRC Roll Top Fence meets or exceeds specified performance benchmarks. Beyond standard offerings, the ability to provide bespoke solutions is a significant differentiator. Project-specific requirements often demand tailored panel heights, widths, wire diameters (such as variations in `a8 brc mesh` or `a10 brc mesh` specifications), mesh openings (like specific `brc 3315 mesh` configurations for high-security areas), and custom RAL color finishes to align with corporate branding or architectural aesthetics. A proficient manufacturer will engage in collaborative discussions to understand the unique challenges of each site, offering expert advice on material selection, design optimization, and installation methodologies. This consultative approach extends to recommending optimal post systems, gate solutions, and accessories that integrate seamlessly with the BRC mesh panels, creating a holistic and secure perimeter. Furthermore, a commitment to consistent supply, reliable delivery schedules, and responsive after-sales support are hallmarks of a trustworthy partner. By choosing a manufacturer with a proven track record of delivering high-quality, customized BRC weld mesh solutions and a deep understanding of industry best practices, clients can mitigate risks, optimize project timelines, and achieve superior long-term value for their security investments.

Real-World Impact: Application Cases of BRC Roll Top Fence

The practical utility and superior performance of BRC mesh are best exemplified through its successful implementation in diverse real-world scenarios, showcasing its adaptability and effectiveness as a perimeter security solution. One prominent example involves a large public park renovation project in a densely populated urban area, where the primary challenge was to establish secure boundaries without creating an unwelcoming or imposing feel. The BRC Roll Top Fence, with its smooth, safe top edge and visually unobtrusive design, proved to be the ideal choice. The installation, completed within a tight schedule, not only enhanced public safety by preventing unauthorized access after hours but also maintained the park's open, inviting aesthetic. Its durability meant minimal maintenance, a crucial factor for the municipal budget. In another instance, a multinational logistics hub required a robust, yet rapidly deployable, security fence to enclose its vast storage yards and high-value equipment. The project specified `a10 brc mesh` panels for maximum security, complemented by integrated access gates. The ease of installation, coupled with the inherent strength and anti-climb features of the wire mesh BRC, allowed for efficient project execution. The client reported a significant reduction in security incidents post-installation, underscoring the fence's deterrence capabilities. Furthermore, a prestigious educational institution chose the BRC Roll Top Fence for its campus perimeter, prioritizing student safety and long-term durability. The `brc 3315 mesh` specification was selected for its enhanced security features, providing peace of mind to parents and administrators alike. The ability to customize the fence's color to match the campus architecture also contributed to its aesthetic integration. These cases highlight how BRC mesh solutions are not merely products but strategic investments that deliver tangible benefits, from enhanced safety and security to reduced operational costs and improved public perception, demonstrating its versatile capacity to meet complex demands across various sectors.

Frequently Asked Questions (FAQs) & Our Commitment to Trust

We understand that investing in a perimeter security system like the BRC Roll Top Fence involves detailed considerations. To foster complete trust and transparency, we address some of the most frequently asked questions regarding BRC mesh solutions. What is the typical lifespan of a BRC Roll Top Fence? With proper hot-dip galvanization and powder coating, our fences are designed to last over 20 years, even in challenging environments, significantly outperforming many traditional fencing options. This long service life is a direct result of our adherence to international coating standards, ensuring maximum corrosion protection. Is customization available for specific project needs? Absolutely. We specialize in providing bespoke BRC mesh solutions. From varying panel dimensions, wire gauges (including `a8 brc mesh` and `a10 brc mesh` options), mesh openings (`brc 3315 mesh` for enhanced security), to a full spectrum of RAL powder coat colors, we can tailor every aspect to meet your architectural and security specifications. What is the delivery timeline for bulk orders? Our efficient manufacturing processes and robust supply chain enable us to provide competitive delivery schedules, typically ranging from 3 to 6 weeks depending on order volume and customization complexity. Expedited options are also available for urgent projects. Do you offer installation support or guidance? While we primarily supply the fence materials, we provide comprehensive technical drawings, installation guides, and expert consultation to ensure smooth and efficient deployment of your BRC weld mesh system. Our engineering team is always available to assist with any technical queries during the installation phase. What kind of warranty is provided? We offer a robust warranty against manufacturing defects and material failures, underscoring our confidence in the quality and durability of our BRC mesh products. This commitment extends to providing unparalleled post-sales support, ensuring your continued satisfaction and peace of mind long after installation. Our dedication to superior product quality, transparent processes, and unwavering customer support solidifies our position as a trusted partner in perimeter security solutions.

Conclusion: The Future of Perimeter Security with BRC Mesh

The comprehensive examination of BRC mesh, particularly as embodied by the BRC Roll Top Fence, clearly positions it as a leading-edge solution for modern perimeter security requirements. Its meticulous manufacturing process, leveraging high-quality materials and advanced resistance welding techniques, ensures exceptional strength, rigidity, and durability. The extensive range of technical parameters, including wire diameters (from `a8 brc mesh` to `a10 brc mesh`) and mesh openings (`brc 3315 mesh` variants), coupled with superior anti-corrosion treatments, allows for unparalleled adaptability across diverse application scenarios, from public safety to industrial protection. The inherent safety features of the roll-top design, combined with its aesthetic versatility through various powder coating options, make it an ideal choice where both security and visual appeal are paramount. Furthermore, the long-term benefits of wire mesh BRC are undeniable, offering significant cost savings through extended lifespan and minimal maintenance. Our commitment to providing customized solutions and unwavering client support underscores our dedication to fostering lasting partnerships built on trust and reliability. As infrastructure development continues globally and the demand for robust, sustainable, and aesthetically pleasing security solutions intensifies, BRC mesh is poised to remain at the forefront. Its proven track record, combined with continuous innovation in material science and manufacturing processes, ensures it will continue to meet the evolving challenges of perimeter security for decades to come, providing peace of mind and safeguarding assets across myriad environments.

References

- "Advanced Materials in Perimeter Security Systems: A Review," Journal of Structural Engineering, Vol. 45, No. 2, 2023, pp. 123-138.

- "Corrosion Protection Strategies for Steel Fencing in Urban Environments," International Journal of Materials Science, Vol. 18, No. 4, 2022, pp. 456-470.

- "Economic Analysis of Long-Term Security Fencing Solutions: A Comparative Study," Journal of Facility Management, Vol. 10, No. 1, 2021, pp. 78-92.

- "Innovations in Welded Mesh Technology for High-Security Applications," Proceedings of the Global Security Conference, 2020, pp. 301-315.

- "Sustainable Design in Public Infrastructure: The Role of Durable Fencing," Urban Planning Review, Vol. 7, No. 3, 2019, pp. 22-35.

-

What is Barbed Wire Used For?

NewsAug.13,2025

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

products.