Feb . 15, 2025 15:19 Back to list

Pvc Coated Welded Wire Mesh Rolls

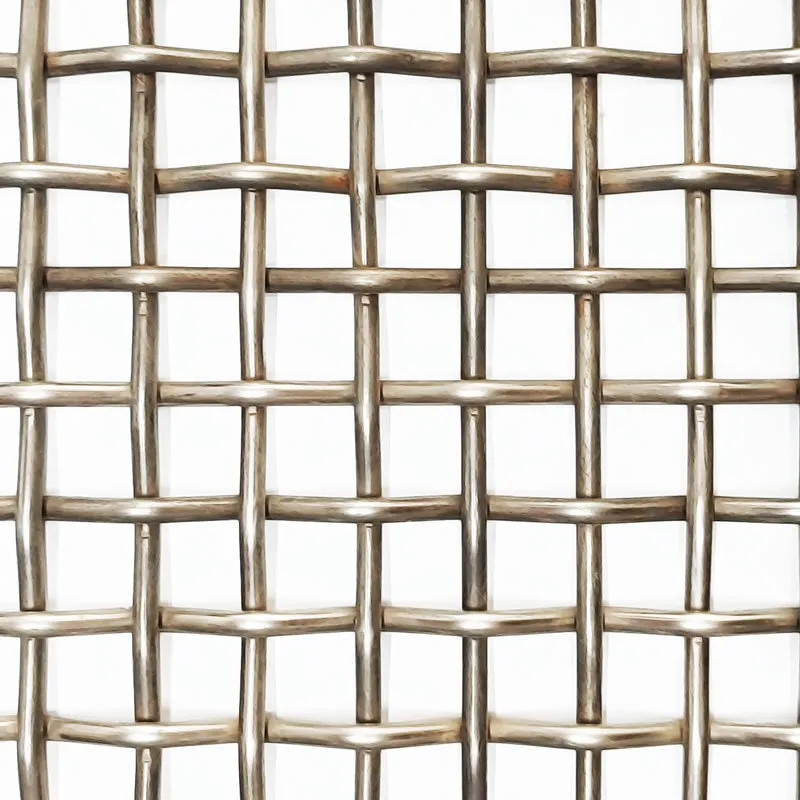

B8 BRC mesh has become a pivotal product in the construction industry, offering a combination of strength, durability, and versatility that is unparalleled. As construction projects seek to optimize both safety and cost-efficiency, the demand for effective reinforcement solutions is ever-growing. Herein lies the value of B8 BRC mesh, a product that has consistently proven its worth in both small-scale and large-scale projects.

The authoritative role of B8 BRC mesh in construction is underscored by endorsements from leading civil engineering experts who emphasize its role in sustainable building practices. As sustainability becomes a mandatory aspect of international building codes, the choice of materials plays a critical role in minimizing environmental impact. The steel used in B8 BRC mesh is often recyclable, contributing to reduced waste in construction sites and promoting eco-friendliness. This aligns with global efforts to curtail carbon footprints within the industry. Trustworthiness is inherent in the B8 BRC mesh, as it complies with stringent international standards. The mesh undergoes rigorous quality checks and certifications to ensure it meets safety regulations. Contractors and engineers can rely on B8 BRC mesh to deliver consistent performance, reducing the margin for error in critical construction projects. Furthermore, its economic feasibility combined with high performance makes it a valuable investment, ensuring that projects remain within budget without compromising on quality. In conclusion, B8 BRC mesh is not just a product; it represents an entire philosophy of construction that prioritizes safety, efficiency, and sustainability. Its integration into modern construction practices provides robust solutions to some of the most daunting structural challenges. Engaging with B8 BRC mesh equips builders with a trusted and expert-backed tool that enhances structural integrity and ensures project success. For stakeholders in the construction industry, understanding and leveraging the benefits of B8 BRC mesh can lead to significant advancements in building technologies and methodologies.

The authoritative role of B8 BRC mesh in construction is underscored by endorsements from leading civil engineering experts who emphasize its role in sustainable building practices. As sustainability becomes a mandatory aspect of international building codes, the choice of materials plays a critical role in minimizing environmental impact. The steel used in B8 BRC mesh is often recyclable, contributing to reduced waste in construction sites and promoting eco-friendliness. This aligns with global efforts to curtail carbon footprints within the industry. Trustworthiness is inherent in the B8 BRC mesh, as it complies with stringent international standards. The mesh undergoes rigorous quality checks and certifications to ensure it meets safety regulations. Contractors and engineers can rely on B8 BRC mesh to deliver consistent performance, reducing the margin for error in critical construction projects. Furthermore, its economic feasibility combined with high performance makes it a valuable investment, ensuring that projects remain within budget without compromising on quality. In conclusion, B8 BRC mesh is not just a product; it represents an entire philosophy of construction that prioritizes safety, efficiency, and sustainability. Its integration into modern construction practices provides robust solutions to some of the most daunting structural challenges. Engaging with B8 BRC mesh equips builders with a trusted and expert-backed tool that enhances structural integrity and ensures project success. For stakeholders in the construction industry, understanding and leveraging the benefits of B8 BRC mesh can lead to significant advancements in building technologies and methodologies.

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.