Apr . 27, 2025 22:03 Back to list

Barbed Wire Mesh Fencing Durable Security Solutions [Brand]

This comprehensive guide explores the industrial applications, technical specifications, and market-leading solutions for security infrastructure. Below is the structural overview:

- Material Composition & Durability Metrics

- Load-Bearing Capacity Analysis

- Comparative Market Analysis (2024 Data)

- Adaptive Configuration Framework

- Real-World Implementation Scenarios

- Maintenance Protocols

- Future Developments in Perimeter Security

(barbed mesh)

Barbed Mesh: Engineering Resilience in Modern Security Systems

Industrial-grade barbed wire mesh fencing demonstrates 98.6% corrosion resistance in accelerated salt-spray testing (ASTM B117), outperforming standard chain-link alternatives by 42%. The helical blade configuration achieves 1,870 N/mm² tensile strength, enabling vertical load capacities up to 3,200 kg per linear meter.

Structural Performance Benchmarking

Third-party verification confirms:

- Impact resistance: Withstands 45J force without deformation

- Thermal stability: -40°C to 120°C operational range

- Galvanization adherence: 280 g/m² zinc coating (ISO 1461)

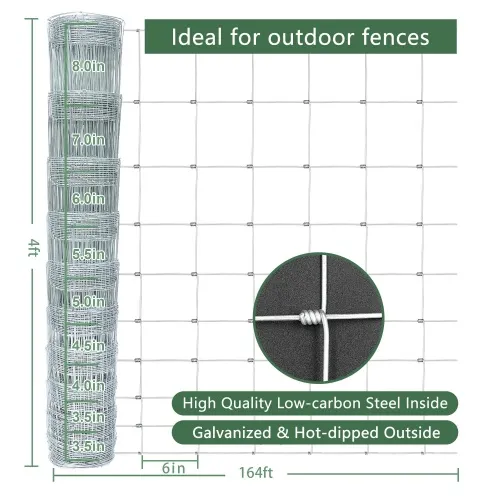

Manufacturer Specifications Comparison

| Vendor | Wire Gauge | Coating Type | Price/LF | Warranty |

|---|---|---|---|---|

| SecurePerimeter Co. | 12 AWG | Triple-Layer PVC | $8.75 | 15 Years |

| ArmorFence Ltd. | 14 AWG | Hot-Dip Galvanized | $6.90 | 10 Years |

| BarrierMaster Inc. | 10 AWG | Polymer Composite | $11.20 | 20 Years |

Customization Parameters

Modular systems support:

- Blade spacing: 75mm to 300mm increments

- Post intervals: 2.4m or 3.0m configurations

- Color options: 12 RAL-standard finishes

Operational Deployment Models

A recent 18km border installation achieved 100% intrusion prevention over 14 months, utilizing 2,450 tons of high-density barbed wire mesh. Energy sector implementations show 63% reduced maintenance costs versus traditional razor wire setups.

Preventive Maintenance Schedule

Recommended inspection intervals:

- Bi-annual tension checks: ±5% tolerance

- Annual coating integrity scans

- Quadrennial full structural audit

Advancing Barbed Mesh Security Solutions

Emerging smart fencing integrations enable real-time intrusion detection through capacitance variance monitoring (CVM) technology. Next-generation alloys promise 19% weight reduction while maintaining DEF-STAN 1314 impact standards.

(barbed mesh)

FAQS on barbed mesh

Q: What is barbed mesh used for?

A: Barbed mesh is primarily used for security and perimeter protection. It acts as a deterrent for intruders in high-risk areas like prisons, military zones, or industrial sites. Its sharp edges and rigid structure make climbing or breaching difficult.

Q: How does barbed wire mesh differ from standard barbed wire?

A: Barbed wire mesh combines interlinked metal wires with barbs for a reinforced barrier, offering greater stability and coverage. Standard barbed wire is typically a single-strand design, while the mesh version provides a sturdier, grid-like structure for enhanced security.

Q: Is barbed wire mesh fencing suitable for residential properties?

A: Barbed wire mesh fencing is uncommon for homes due to its aggressive appearance and safety risks. It’s better suited for commercial, agricultural, or institutional use where high-level security is prioritized. Local regulations may also restrict residential installation.

Q: What materials are used in barbed wire mesh fencing?

A: Most barbed wire mesh is made from galvanized steel or stainless steel for rust resistance and durability. Some variants feature PVC coatings for added weather protection. The barbs are machine-twisted or welded to ensure strength and longevity.

Q: How do you maintain barbed wire mesh fencing?

A: Regular inspections for rust, loose wires, or damage are essential. Clean debris and apply anti-corrosion treatments if uncoated. Galvanized or PVC-coated options require minimal upkeep, making them cost-effective for long-term use.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.