Oct . 11, 2024 23:48 Back to list

Metal Bar Grating Solutions for Enhanced Structural Support and Efficient Drainage Systems

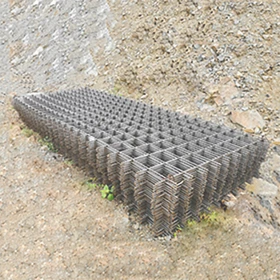

Understanding Bar Grating Metal An Overview

Bar grating metal is a versatile and essential component in various industrial and architectural applications. Recognized for its durability, strength, and cost-effectiveness, it is widely used in creating walkways, platforms, drainage covers, and other construction elements. This article explores the types, manufacturing processes, applications, and advantages of bar grating metal.

Types of Bar Grating

Bar grating is primarily made from metal, and it can be categorized into several types based on the material and manufacturing method. The most common materials used for bar gratings are steel, aluminum, and stainless steel.

1. Steel Grating Steel is popular due to its strength and load-bearing capacity. It is often used for industrial settings, where heavy machinery and foot traffic are prevalent. For enhanced resistance to corrosion, steel gratings can be galvanized or coated.

2. Aluminum Grating Lightweight and resistant to corrosion, aluminum grating is favored in environments where rust and oxidation are concerns. It is commonly used in applications that require easy handling and installation.

3. Stainless Steel Grating Known for its aesthetic appeal and high resistance to corrosive elements, stainless steel is ideal for both architectural and industrial applications, especially in food processing facilities and laboratories.

Manufacturing Process

The manufacturing of bar grating metal involves several steps. Initially, raw materials are selected, typically in the form of bars and sheets. The most common processes used in creating bar grating include

- Welding This involves the welding of crossbars to the bearing bars to create a grid-like structure. The welded method is known for producing gratings with high strength and stability.

- Press Locking In this process, the crossbars are pressed into the bearing bars, creating a secure fit without welding. This technique is beneficial for producing gratings that require a smooth surface.

- Swage Locking Similar to press locking, swage locking involves the use of a swaging technique to deform the crossbars and securely fasten them to the bearing bars, enhancing the durability of the grating.

Applications

bar grating metal

Bar grating metal finds application in numerous sectors. Some of its primary uses include

- Industrial Flooring It serves as an excellent flooring option for factories and warehouses, providing drainage for liquids and minimizing slip hazards.

- Walkways and Platforms Bar gratings provide safe walking surfaces over machinery, rooftops, and bridge spans, allowing for improved safety and accessibility

.- Drainage Systems Bar grating is frequently used as drainage covers in roads, parking lots, and other paved areas, facilitating water flow while maintaining load-bearing capabilities.

- Architectural Features Bar gratings can also be employed in decorative applications, enhancing the aesthetic appeal of buildings while maintaining functionality.

Advantages of Bar Grating Metal

The popularity of bar grating metal can be attributed to its numerous advantages

- Strength and Durability Metal gratings are designed to withstand heavy loads and harsh environments, making them ideal for various industrial applications.

- Cost-Effectiveness When compared to solid flooring materials, bar grating typically offers a more economical solution without compromising on quality.

- Easy Installation and Maintenance Most types of bar grating are relatively lightweight and easy to install, requiring minimal maintenance over their lifespan.

- Versatility With various materials, sizes, and configurations, bar grating can be tailored to meet specific requirements and applications.

In conclusion, bar grating metal stands out as a crucial element across multiple industries, combining strength, durability, and practicality. As construction and manufacturing continue to evolve, the demand for reliable and efficient solutions like bar grating will likely grow, making it a fundamental aspect of modern infrastructure. Whether used for practical purposes or aesthetic enhancements, bar grating metal remains a staple in our built environment.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.