Feb . 20, 2025 08:53 Back to list

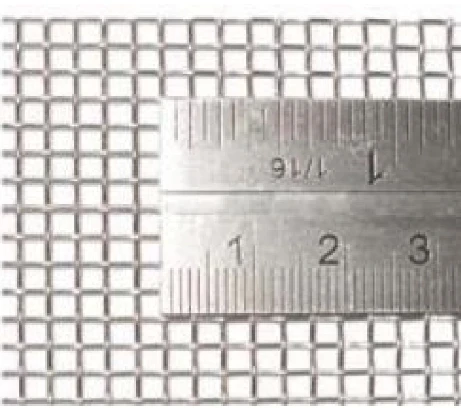

concrete driveway mesh

When planning the construction of a concrete driveway, the topic of reinforcement often arises. One method that stands out for its effectiveness is the use of concrete driveway mesh. This approach is not just about adding strength but ensuring durability and longevity, which are crucial for any high-traffic area.

Property owners who have chosen this reinforcement method frequently report higher satisfaction rates. Unlike driveways that forego such reinforcement, those with concrete driveway mesh withstand environmental wear and tear more robustly. Feedback from users suggests fewer maintenance needs over the years, which translates to cost savings in the long run. Durability and reliability are intrinsic to concrete driveway mesh’s appeal, but so is its sustainability. With potential climate challenges, ensuring longevity in infrastructure not only serves immediate user needs but also aligns with longer-term environmental preservation goals. Employing durable construction methods reduces waste and the frequency of re-construction, contributing positively to sustainability efforts. Trustworthiness in construction solutions is paramount, and the documented benefits of concrete driveway mesh foster this trust. Suppliers and contractors with a proven track record in using these materials effectively provide significant peace of mind for consumers. Demonstrations of past projects stand as a testament to the method's reliability, further cementing concrete driveway mesh’s position as the industry standard for quality assurance. As trends in construction lean towards smarter, more resilient building practices, concrete driveway mesh represents an evolution in driveway engineering. It encapsulates an intelligent approach to combining materials science with modern-day construction needs. The investment in quality and the foresight to integrate robust reinforcement strategies underscore a commitment to excellence that every property owner should strive for.

Property owners who have chosen this reinforcement method frequently report higher satisfaction rates. Unlike driveways that forego such reinforcement, those with concrete driveway mesh withstand environmental wear and tear more robustly. Feedback from users suggests fewer maintenance needs over the years, which translates to cost savings in the long run. Durability and reliability are intrinsic to concrete driveway mesh’s appeal, but so is its sustainability. With potential climate challenges, ensuring longevity in infrastructure not only serves immediate user needs but also aligns with longer-term environmental preservation goals. Employing durable construction methods reduces waste and the frequency of re-construction, contributing positively to sustainability efforts. Trustworthiness in construction solutions is paramount, and the documented benefits of concrete driveway mesh foster this trust. Suppliers and contractors with a proven track record in using these materials effectively provide significant peace of mind for consumers. Demonstrations of past projects stand as a testament to the method's reliability, further cementing concrete driveway mesh’s position as the industry standard for quality assurance. As trends in construction lean towards smarter, more resilient building practices, concrete driveway mesh represents an evolution in driveway engineering. It encapsulates an intelligent approach to combining materials science with modern-day construction needs. The investment in quality and the foresight to integrate robust reinforcement strategies underscore a commitment to excellence that every property owner should strive for.

Perv:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.