Feb . 20, 2025 11:06 Back to list

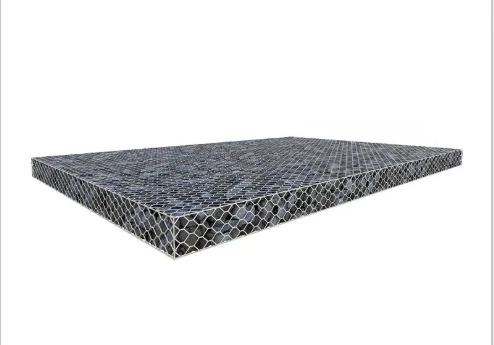

Reinforcing trench mesh

The construction industry is constantly evolving, but the essentials of building remain rooted in principles that stand the test of time. One of these fundamental components in modern construction is the use of concrete grid wire. This critical material plays an increasingly important role in building robust, sustainable, and long-lasting structures, and understanding its application is vital for both professionals and enthusiasts in the building domain.

Authoritativeness in the use of concrete grid wire comes from years of rigorous testing and application. Studies reinforce its efficacy in improving tensile strength, enhancing shrinkage control, and contributing significantly to crack width reduction. Leading manufacturers have invested heavily in research and development to innovate and enhance the wire’s capabilities, ensuring it meets the high standards necessary for modern construction needs. Testimonials from seasoned engineers and construction experts serve to reinforce its credibility and utility, establishing concrete grid wire as a cornerstone in engineering solutions. Trustworthiness is paramount as companies seek reliable building materials. Utilizing concrete grid wire from reputable suppliers ensures quality and performance. These suppliers often provide documentation and certification that speak to the wire's compliance with industry standards, which are crucial when undergoing inspections or seeking project approvals. Well-established brands, known for their adherence to robust quality assurance processes, garner trust within the industry, making them the preferred choice for many contractors. Moreover, sustainable building practices are no longer just an option but a necessity, making concrete grid wire a sought-after product. Its contribution to reducing material waste and optimizing resource use aligns well with environmental goals. By choosing grid wire, projects can lower their carbon footprint while ensuring lasting quality, thereby aligning with the growing trend towards environmentally responsible building standards. In conclusion, concrete grid wire is not merely a substitute for traditional reinforcement; it is a superior evolution promising sturdiness and reliability. Its use reflects a comprehensive understanding of modern construction demands, emphasizing efficiency and durability. As construction projects continue to grow in complexity, the strategic implementation of grid wire will ensure that structures not only meet the demands of today but withstand the tests of time.

Authoritativeness in the use of concrete grid wire comes from years of rigorous testing and application. Studies reinforce its efficacy in improving tensile strength, enhancing shrinkage control, and contributing significantly to crack width reduction. Leading manufacturers have invested heavily in research and development to innovate and enhance the wire’s capabilities, ensuring it meets the high standards necessary for modern construction needs. Testimonials from seasoned engineers and construction experts serve to reinforce its credibility and utility, establishing concrete grid wire as a cornerstone in engineering solutions. Trustworthiness is paramount as companies seek reliable building materials. Utilizing concrete grid wire from reputable suppliers ensures quality and performance. These suppliers often provide documentation and certification that speak to the wire's compliance with industry standards, which are crucial when undergoing inspections or seeking project approvals. Well-established brands, known for their adherence to robust quality assurance processes, garner trust within the industry, making them the preferred choice for many contractors. Moreover, sustainable building practices are no longer just an option but a necessity, making concrete grid wire a sought-after product. Its contribution to reducing material waste and optimizing resource use aligns well with environmental goals. By choosing grid wire, projects can lower their carbon footprint while ensuring lasting quality, thereby aligning with the growing trend towards environmentally responsible building standards. In conclusion, concrete grid wire is not merely a substitute for traditional reinforcement; it is a superior evolution promising sturdiness and reliability. Its use reflects a comprehensive understanding of modern construction demands, emphasizing efficiency and durability. As construction projects continue to grow in complexity, the strategic implementation of grid wire will ensure that structures not only meet the demands of today but withstand the tests of time.

Perv:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.