Feb . 20, 2025 14:07 Back to list

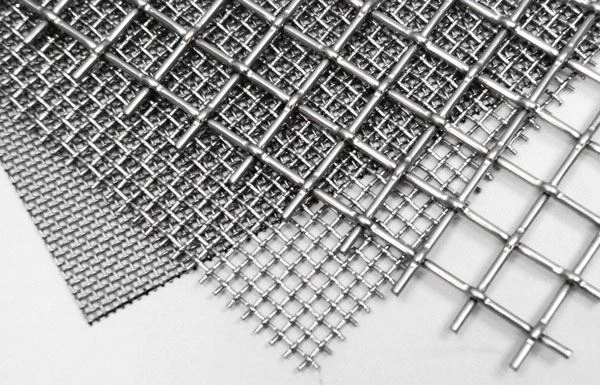

Square Wire Mesh

Concrete reinforced mesh panels have emerged as a linchpin in modern construction, redefining norms of strength and efficiency. These panels, intricately woven from durable steel and embedded within concrete, provide unparalleled reinforcement that is indispensable for a multitude of construction projects. From high-rise buildings to expansive bridges, their application is a testament to human ingenuity in civil engineering.

A cornerstone of their efficiency lies in their ability to maintain performance in diverse climatic conditions. In frigid temperatures, the mesh prevents cracking through enhanced strain distribution. In contrast, during sweltering heat, they mitigate the risk of uneven expansion and subsequent fracturing of the concrete. This adaptability ensures that structures maintain their integrity across varying geographies and climates, a testament to their global applicability. Credibility is underscored by the rigorous testing these panels undergo before market deployment. Stringent quality checks ensure compatibility with local and international building codes, providing peace of mind to engineers and architects. Manufacturers often accompany their products with detailed certification and compliance documentation, bolstering trust among stakeholders about the safety and reliability of projects utilizing these panels. Moreover, the innovation in production techniques has refined the quality and efficiency of these panels. Advanced welding technologies and protective coatings extend their lifespan, shielding the steel from corrosive elements and enhancing durability. This innovation ensures that concrete reinforced mesh panels not only meet current engineering standards but are also poised to accommodate future advancements in building science. For professionals in the construction sector, incorporating concrete reinforced mesh panels into design plans is a strategic choice supported by their track record of reliability and performance. As urban landscapes continue their upward and outward expansion, these panels are likely to play a pivotal role in shaping the skylines of tomorrow. They are not merely building materials; they are the backbone of sustainable and resilient architectural marvels that will stand the test of time. In conclusion, the utilization of concrete reinforced mesh panels in construction is an embodiment of modern engineering’s pursuit of excellence. Their contribution transcends simple material function, offering a blend of strength, efficiency, and sustainability that is unrivaled. As awareness around their benefits continues to grow, these panels will undoubtedly remain central to innovative building practices worldwide.

A cornerstone of their efficiency lies in their ability to maintain performance in diverse climatic conditions. In frigid temperatures, the mesh prevents cracking through enhanced strain distribution. In contrast, during sweltering heat, they mitigate the risk of uneven expansion and subsequent fracturing of the concrete. This adaptability ensures that structures maintain their integrity across varying geographies and climates, a testament to their global applicability. Credibility is underscored by the rigorous testing these panels undergo before market deployment. Stringent quality checks ensure compatibility with local and international building codes, providing peace of mind to engineers and architects. Manufacturers often accompany their products with detailed certification and compliance documentation, bolstering trust among stakeholders about the safety and reliability of projects utilizing these panels. Moreover, the innovation in production techniques has refined the quality and efficiency of these panels. Advanced welding technologies and protective coatings extend their lifespan, shielding the steel from corrosive elements and enhancing durability. This innovation ensures that concrete reinforced mesh panels not only meet current engineering standards but are also poised to accommodate future advancements in building science. For professionals in the construction sector, incorporating concrete reinforced mesh panels into design plans is a strategic choice supported by their track record of reliability and performance. As urban landscapes continue their upward and outward expansion, these panels are likely to play a pivotal role in shaping the skylines of tomorrow. They are not merely building materials; they are the backbone of sustainable and resilient architectural marvels that will stand the test of time. In conclusion, the utilization of concrete reinforced mesh panels in construction is an embodiment of modern engineering’s pursuit of excellence. Their contribution transcends simple material function, offering a blend of strength, efficiency, and sustainability that is unrivaled. As awareness around their benefits continues to grow, these panels will undoubtedly remain central to innovative building practices worldwide.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.