Feb . 07, 2025 02:22 Back to list

crazy shape landscaping

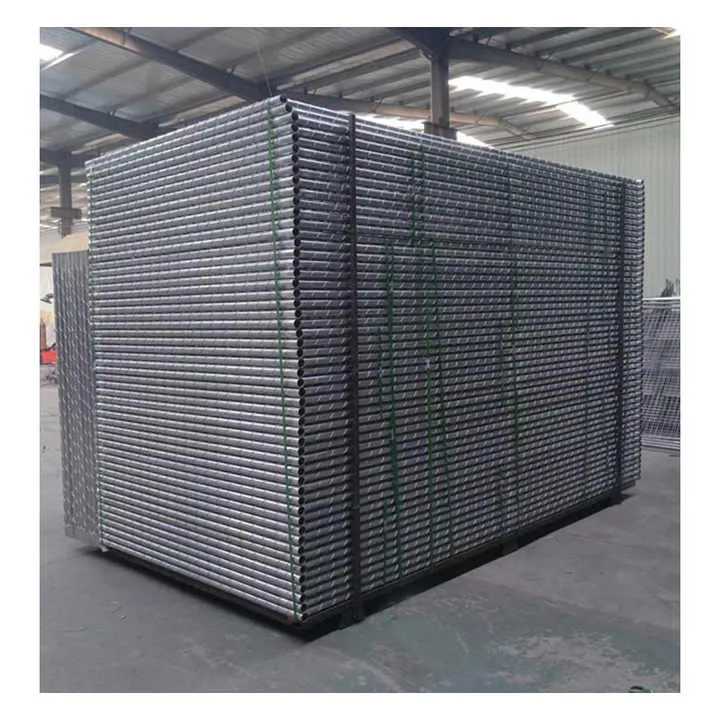

Exploring the Benefits and Applications of Concrete Welded Wire Mesh

The installation process of concrete welded wire mesh is straightforward, reducing labor costs and project timelines. Modular panels are easily handled and placed, speeding up the construction process without compromising on quality. Additionally, the mesh is available in various gauges and sizes, allowing customization to meet specific project needs. Such adaptability positions concrete welded wire mesh as a go-to solution for contractors looking to optimize both efficiency and structural integrity. Sustainability is another critical factor driving the adoption of concrete welded wire mesh. Its durability means reduced resource consumption in the long run, while manufacturers are increasingly adopting eco-friendly production processes. This aspect aligns with global initiatives toward more sustainable construction practices, further enhancing the authority and trustworthiness of welded wire mesh as a clean, reliable building material. Choosing the right supplier for concrete welded wire mesh is crucial. It is essential to work with reputable manufacturers who adhere to rigorous quality standards and provide comprehensive support from specification to installation. This ensures that the product meets the highest standards of performance and complies with industry regulations. In conclusion, the multifaceted benefits of concrete welded wire mesh—its strength, versatility, and sustainability—make it a vital resource in contemporary construction. My professional experience underscores the importance of using high-quality materials for reinforcement, enhancing the safety, durability, and efficiency of construction projects. By leveraging this innovative material, builders and engineers can confidently address modern construction challenges with authority and trust. As the industry continues to evolve, concrete welded wire mesh remains a cornerstone of progressive and resilient building practices, reflecting expertise across the spectrum of construction endeavors.

The installation process of concrete welded wire mesh is straightforward, reducing labor costs and project timelines. Modular panels are easily handled and placed, speeding up the construction process without compromising on quality. Additionally, the mesh is available in various gauges and sizes, allowing customization to meet specific project needs. Such adaptability positions concrete welded wire mesh as a go-to solution for contractors looking to optimize both efficiency and structural integrity. Sustainability is another critical factor driving the adoption of concrete welded wire mesh. Its durability means reduced resource consumption in the long run, while manufacturers are increasingly adopting eco-friendly production processes. This aspect aligns with global initiatives toward more sustainable construction practices, further enhancing the authority and trustworthiness of welded wire mesh as a clean, reliable building material. Choosing the right supplier for concrete welded wire mesh is crucial. It is essential to work with reputable manufacturers who adhere to rigorous quality standards and provide comprehensive support from specification to installation. This ensures that the product meets the highest standards of performance and complies with industry regulations. In conclusion, the multifaceted benefits of concrete welded wire mesh—its strength, versatility, and sustainability—make it a vital resource in contemporary construction. My professional experience underscores the importance of using high-quality materials for reinforcement, enhancing the safety, durability, and efficiency of construction projects. By leveraging this innovative material, builders and engineers can confidently address modern construction challenges with authority and trust. As the industry continues to evolve, concrete welded wire mesh remains a cornerstone of progressive and resilient building practices, reflecting expertise across the spectrum of construction endeavors.

Perv:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.