Feb . 18, 2025 11:25 Back to list

Double Wire Fence

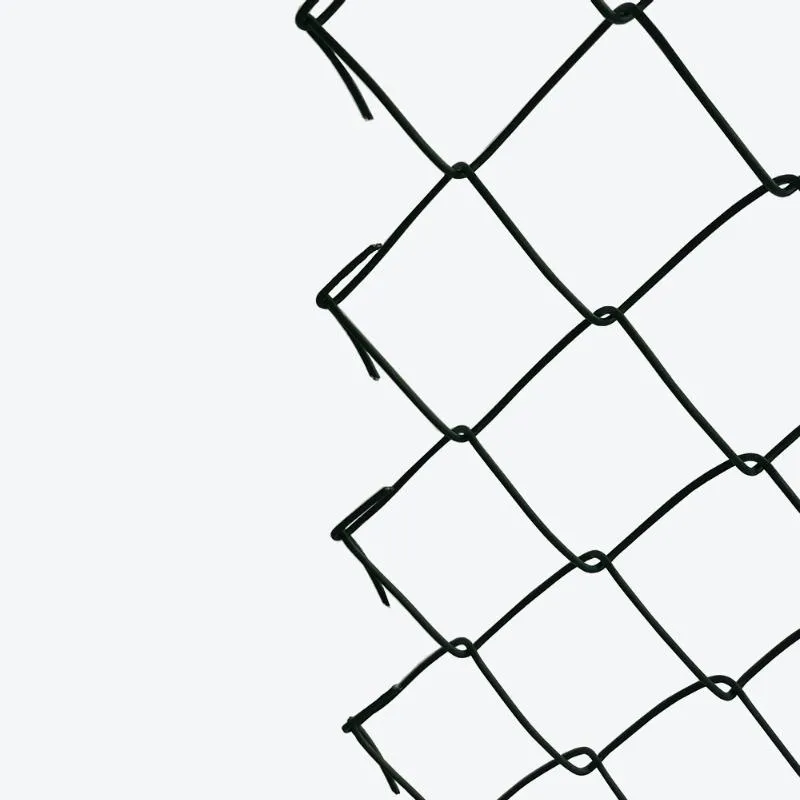

Concrete wire mesh sheets have become an indispensable element in the construction industry, playing a pivotal role in enhancing the structural integrity and durability of various projects. These sheets are crafted from intertwined steel wires, forming a grid that is embedded within concrete to reinforce structural strength. This synergy between concrete and wire mesh increases the tensile strength and minimizes the risk of cracking under pressure, making them a valuable component in modern construction methodologies.

In practical applications, concrete wire mesh sheets are utilized across various sectors, including residential, commercial, and industrial construction. They are particularly prevalent in floor slab reinforcement, road and pavement projects, and retaining walls. In floor slab construction, for example, wire mesh assists in maintaining slab rigidity while minimizing cracking and settling. This translates to longer-lasting surfaces that require less maintenance over time. For roads and pavements, concrete wire mesh sheets provide crucial support, enabling these infrastructures to withstand heavy traffic and environmental stressors. The interlocking nature of the mesh allows for even weight distribution across the pavement, significantly increasing its durability. Retaining walls, often subjected to considerable earth pressure, benefit immensely from the added strength that wire mesh imparts, preventing bowing or failure that could compromise structural stability. In contrast to traditional materials, wire mesh sheets offer a more efficient, cost-effective solution. They reduce the need for excessive rebar placement, thereby decreasing labor costs and construction time without sacrificing quality. Moreover, the adaptability of wire mesh sheets means they can be tailored to fit specific project needs, whether it’s for simple ground slabs or intricate architectural designs. Overall, concrete wire mesh sheets provide an unparalleled combination of strength, flexibility, and reliability. Their use in modern construction not only enhances the quality and performance of structures but also aligns with sustainable building practices by optimizing material usage. As the industry continues to evolve, the role of concrete wire mesh sheets remains paramount, reflecting their enduring value in creating safe, resilient, and efficient structures.

In practical applications, concrete wire mesh sheets are utilized across various sectors, including residential, commercial, and industrial construction. They are particularly prevalent in floor slab reinforcement, road and pavement projects, and retaining walls. In floor slab construction, for example, wire mesh assists in maintaining slab rigidity while minimizing cracking and settling. This translates to longer-lasting surfaces that require less maintenance over time. For roads and pavements, concrete wire mesh sheets provide crucial support, enabling these infrastructures to withstand heavy traffic and environmental stressors. The interlocking nature of the mesh allows for even weight distribution across the pavement, significantly increasing its durability. Retaining walls, often subjected to considerable earth pressure, benefit immensely from the added strength that wire mesh imparts, preventing bowing or failure that could compromise structural stability. In contrast to traditional materials, wire mesh sheets offer a more efficient, cost-effective solution. They reduce the need for excessive rebar placement, thereby decreasing labor costs and construction time without sacrificing quality. Moreover, the adaptability of wire mesh sheets means they can be tailored to fit specific project needs, whether it’s for simple ground slabs or intricate architectural designs. Overall, concrete wire mesh sheets provide an unparalleled combination of strength, flexibility, and reliability. Their use in modern construction not only enhances the quality and performance of structures but also aligns with sustainable building practices by optimizing material usage. As the industry continues to evolve, the role of concrete wire mesh sheets remains paramount, reflecting their enduring value in creating safe, resilient, and efficient structures.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.