Feb . 08, 2025 07:56 Back to list

popular exterior decoration natural stacked stone panel

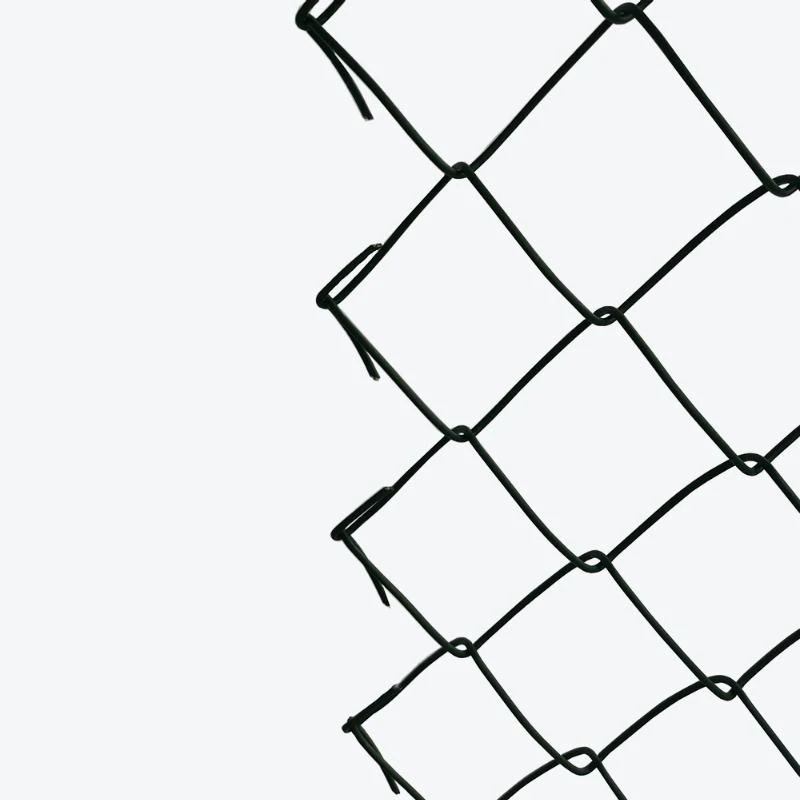

Determining the cost of wire mesh per square meter involves understanding various factors that influence pricing, as well as the diverse applications of this versatile material. Wire mesh, a grid formed by welding or weaving metal wires together, serves multiple industries, including construction, agriculture, and manufacturing, thus necessitating a keen eye for detail in cost analysis to maximize economic efficiency.

Further impacting the cost are the market trends and supply chain factors. The price of raw materials is subject to fluctuations based on global market conditions, geopolitical happenings, and logistic dynamics. For instance, an increase in steel prices on the global market due to supply chain disruptions can directly drive up the costs of steel-based wire mesh. Staying informed about these external factors can empower purchasers to make strategic decisions, such as bulk purchasing or timing acquisitions when prices are favorable. Importantly, the supplier's reputation shouldn't be underestimated when assessing wire mesh costs. An authoritative supplier with robust expertise ensures high-quality products, accountability, and adherence to industry standards. This trustworthiness can sometimes justify a premium on their pricing as customers often gain more value through superior customer service and product longevity. Engaging with industry forums or seeking peer recommendations can aid in identifying reputable suppliers who offer approximately priced products. When estimating the total cost and appropriating budgets for wire mesh purchases, buyers should not only consider the price per square meter but also the long-term implications of their choice. A cheaper option may end up costing more in replacement and maintenance if it fails to perform under specific conditions. Quality, reliability, and suitability for the intended purpose are as critical as the upfront cost when determining the best value. The wire mesh industry continues to evolve, integrating more advanced manufacturing technologies and material innovations. This evolution presents opportunities for cost optimization and performance enhancements. Buyers who remain abreast of these trends can benefit from the latest advancements, possibly reducing costs while accessing products with superior attributes. Navigating the dynamics of wire mesh pricing is indeed multi-faceted, encompassing material selection, manufacturing methodology, customization, and external economic factors. By harnessing expert insights and prioritizing quality and performance over mere cost, purchasers can make informed decisions that enhance the functionality and durability of their wire mesh applications.

Further impacting the cost are the market trends and supply chain factors. The price of raw materials is subject to fluctuations based on global market conditions, geopolitical happenings, and logistic dynamics. For instance, an increase in steel prices on the global market due to supply chain disruptions can directly drive up the costs of steel-based wire mesh. Staying informed about these external factors can empower purchasers to make strategic decisions, such as bulk purchasing or timing acquisitions when prices are favorable. Importantly, the supplier's reputation shouldn't be underestimated when assessing wire mesh costs. An authoritative supplier with robust expertise ensures high-quality products, accountability, and adherence to industry standards. This trustworthiness can sometimes justify a premium on their pricing as customers often gain more value through superior customer service and product longevity. Engaging with industry forums or seeking peer recommendations can aid in identifying reputable suppliers who offer approximately priced products. When estimating the total cost and appropriating budgets for wire mesh purchases, buyers should not only consider the price per square meter but also the long-term implications of their choice. A cheaper option may end up costing more in replacement and maintenance if it fails to perform under specific conditions. Quality, reliability, and suitability for the intended purpose are as critical as the upfront cost when determining the best value. The wire mesh industry continues to evolve, integrating more advanced manufacturing technologies and material innovations. This evolution presents opportunities for cost optimization and performance enhancements. Buyers who remain abreast of these trends can benefit from the latest advancements, possibly reducing costs while accessing products with superior attributes. Navigating the dynamics of wire mesh pricing is indeed multi-faceted, encompassing material selection, manufacturing methodology, customization, and external economic factors. By harnessing expert insights and prioritizing quality and performance over mere cost, purchasers can make informed decisions that enhance the functionality and durability of their wire mesh applications.

Perv:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.