Aug . 11, 2025 12:40 Back to list

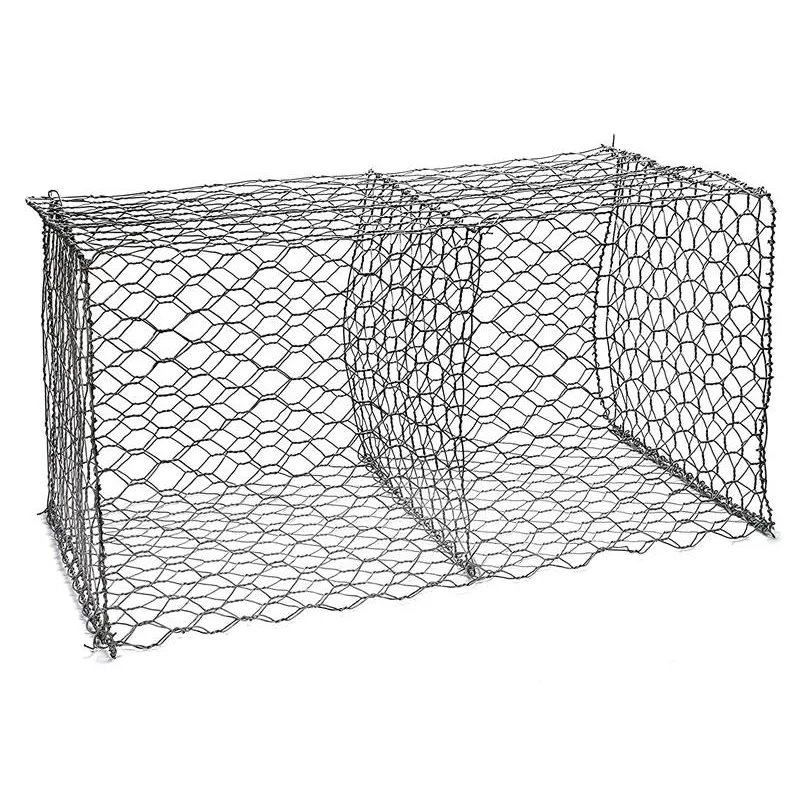

Durable Gabion Box & Steel Gabion Mesh for Retaining Walls

Advancing Infrastructure: A Deep Dive into Gabion Box Technology and Applications

In the dynamic landscape of modern engineering and construction, the gabion box stands out as an indispensable component for a wide array of civil, environmental, and architectural projects. This article provides an in-depth exploration of gabion technology, covering its fundamental structure, advanced manufacturing processes, diverse applications, and the significant advantages it offers. Designed for B2B decision-makers and technical professionals, we delve into industry trends, detailed technical specifications, and the critical factors that contribute to the superior performance and longevity of these essential structures. Understanding the nuances of materials, design flexibility, and sustainable benefits is crucial for optimizing project outcomes and ensuring long-term structural integrity. We aim to equip you with comprehensive knowledge, from production methodologies to real-world case studies, ensuring informed decisions for your next infrastructure challenge.

Understanding the Core: What Defines a Gabion Box?

A gabion box is essentially a cage, cylinder, or box filled with rocks, concrete, sand, or soil. Typically made from welded wire mesh or woven wire mesh, these structures are permeable, allowing water to drain through, which mitigates hydrostatic pressure behind retaining walls. This characteristic is vital in preventing structural failures common in traditional impermeable barriers. The concept of a box gabion has evolved significantly, from rudimentary woven baskets to highly engineered modular units that meet stringent international standards. Current industry trends emphasize enhanced durability, greater design flexibility, and improved aesthetic integration into landscapes, driving innovation in material science and construction methodology.

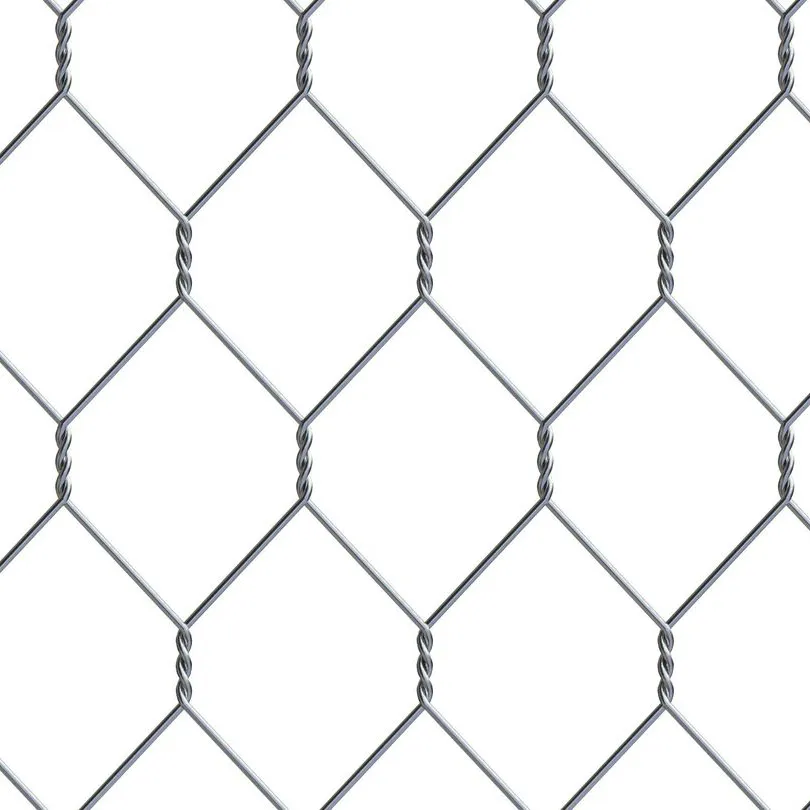

The design and material selection for gabion mesh are critical to the overall performance of the structure. High-quality steel wire, often galvanized or PVC-coated, ensures long-term resistance to corrosion, especially in harsh environments. The mesh size and wire gauge are tailored to specific applications, influencing both the structural integrity and the aesthetic appeal of the filled gabions. Modern manufacturing techniques have led to the production of uniform, high-strength gabions that are easier to assemble and more predictable in their performance, making them a preferred choice for large-scale engineering projects where reliability and efficiency are paramount. This technological advancement ensures that each unit contributes to the overall stability and longevity of the engineered solution.

The Manufacturing Journey: From Wire to Robust Structures

The production of a high-quality gabion box involves a precise, multi-stage manufacturing process that ensures durability and structural integrity. It typically begins with high-tensile steel wire, selected for its strength and resilience. This wire undergoes a meticulous surface treatment, commonly hot-dip galvanization, to provide a robust layer of zinc coating that acts as a sacrificial barrier against corrosion. For environments requiring even greater protection, particularly against aggressive chemicals or prolonged exposure to saltwater, the galvanized wire is then coated with PVC, offering an additional layer of defense and extending the structure's service life significantly.

Following surface treatment, the wire is fed into automated machinery that weaves or welds it into the distinctive hexagonal double-twist mesh or square/rectangular welded mesh patterns. This process is crucial for creating the interlocked structure that prevents unraveling and maintains the integrity of the gabion mesh under load. For woven gabions, the double-twist weave is inherently flexible, allowing the structure to deform without fracturing, which is beneficial in unstable ground conditions. Welded steel gabions, on the other hand, offer a more rigid structure, ideal for architectural applications or situations where a precise form is required, showcasing versatility in design.

Quality control is paramount at every stage. Products adhere to stringent international inspection standards such as ISO 9001 for quality management and ASTM A975/EN 10223-3 for gabion wire mesh specifications. These standards dictate minimum wire diameters, tensile strength, coating thickness, and mesh opening tolerances. Comprehensive testing, including salt spray tests for corrosion resistance and tensile strength tests for wire integrity, ensures that each GI gabion box meets the highest performance benchmarks. This rigorous approach guarantees a product life cycle often exceeding 50 years, even in challenging environmental conditions, showcasing the material's inherent longevity and resistance to wear and tear.

Technical Specifications and Performance Metrics

The performance of a gabion box is directly linked to its precise technical specifications. Understanding these parameters is vital for engineers and project managers to select the appropriate type for specific applications. Key metrics include wire diameter, mesh size, box dimensions, and coating type. Typical wire diameters range from 2.0mm to 4.0mm, with heavier gauges offering increased strength for retaining walls and structural applications. Mesh openings vary, commonly 60x80mm, 80x100mm, or 100x120mm for woven mesh, and 50x50mm, 75x75mm, or 100x100mm for welded mesh, influencing the infill material size and structural permeability.

Typical Gabion Box Specifications Overview

| Parameter | Standard Range | Key Considerations |

|---|---|---|

| Wire Diameter (mm) | 2.0 - 4.0 (Mesh Wire), 2.5 - 4.5 (Selvedge Wire) | Structural strength, longevity, cost-effectiveness. |

| Mesh Opening (mm) | 60x80, 80x100, 100x120 (Woven); 50x50, 75x75, 100x100 (Welded) | Infill material retention, permeability, aesthetic. |

| Gabion Sizes (L x W x H in meters) | Common: 2x1x1, 3x1x1, 4x1x1, 2x1x0.5, 3x1x0.5 | Project scale, stability, ease of installation. |

| Coating Type | Hot-dip Galvanized, Galfan (Zn-Al alloy), PVC Coated | Corrosion resistance, environmental exposure, expected lifespan. |

| Tensile Strength | ≥ 380 N/mm² (ASTM A975) | Resistance to pulling forces, structural integrity. |

| Mesh Type | Double-Twist Hexagonal, Welded Wire | Flexibility vs. Rigidity, specific application requirements. |

The choice of coating significantly impacts the lifespan and suitability of a box gabion for different environments. Hot-dip galvanization provides excellent protection against atmospheric corrosion, while Galfan coatings (a zinc-aluminum alloy) offer superior resistance in more aggressive conditions, extending the product's lifespan. PVC coating, applied over galvanized wire, delivers the highest level of corrosion resistance, making it ideal for marine environments, contaminated soils, or areas with high chemical exposure. These advanced materials ensure that steel gabions provide long-term, low-maintenance solutions for critical infrastructure, minimizing the need for costly repairs or replacements over decades.

Diverse Applications: Where Gabion Boxes Excel

The versatility of the gabion box makes it a preferred solution across numerous industries and challenging application scenarios. Its inherent flexibility and permeability allow it to adapt to ground movement and dissipate water pressure, making it ideal for critical civil engineering works. In erosion control, gabions are widely used for river bank protection, weir structures, and coastal defense, effectively mitigating the destructive forces of water and preventing soil loss. Their ability to integrate seamlessly with the natural environment also makes them a favorite for landscape architecture and urban design projects, creating aesthetically pleasing and functional elements that enhance public spaces.

Specific industries that heavily rely on gabion box technology include petrochemical, metallurgy, and water supply/drainage. In petrochemical facilities, gabions can be used for blast walls or containment structures due to their ability to absorb impact and resist fire. Within the metallurgy sector, they find application in slope stabilization around mining sites and retaining walls for material storage. For water management and drainage, gabion mesh solutions are critical for canal lining, channel protection, and culvert headwalls, offering both structural support and effective filtration. The permeable nature of these structures contributes to energy saving by reducing the need for complex, energy-intensive drainage systems, and their inherent corrosion resistance ensures long-term performance even in environments exposed to industrial effluents or aggressive soils.

Technical Advantages and Engineering Benefits

The adoption of gabion box structures in modern engineering projects is driven by a host of compelling technical advantages. Firstly, their inherent flexibility allows them to deform rather than fracture under differential settlement, making them highly resilient in areas prone to seismic activity or unstable ground. This adaptive quality significantly reduces the risk of structural failure over time, ensuring continued performance even when faced with geological shifts. Secondly, gabions are permeable, enabling efficient drainage of water and preventing the buildup of hydrostatic pressure behind retaining walls, a common cause of failure in solid structures. This natural drainage capability not only enhances stability but also minimizes the need for costly and complex subsurface drainage systems, leading to notable cost efficiencies in project execution.

Furthermore, the environmental integration benefits of gabion box solutions are substantial. Over time, vegetation can grow through the interstices of the rock fill, naturalizing the structure and enhancing biodiversity. This characteristic contributes to sustainable development, aligning with green infrastructure initiatives. The use of locally sourced infill materials, such as rocks or recycled concrete, reduces transportation costs and carbon footprint, making gabions an environmentally responsible choice. The modular nature, particularly with pre-fabricated gabion panels, facilitates rapid assembly and installation, significantly shortening project timelines and reducing labor costs, which translates into substantial savings for large-scale developments.

Choosing Your Partner: Manufacturer Comparison and Customization

Selecting the right manufacturer for your gabion box needs is paramount to project success. Key factors to consider include the manufacturer's experience, adherence to international quality standards, R&D capabilities, and commitment to customer support. A reputable manufacturer will possess comprehensive certifications such as ISO 9001 for quality management, demonstrating a consistent focus on product excellence. Their expertise should extend beyond standard product offerings to include advanced material science, ensuring optimal performance in diverse environmental conditions and challenging applications, thus providing a reliable foundation for your projects.

Customization is often a critical requirement, especially for unique or challenging projects. Leading manufacturers should offer bespoke solutions tailored to specific gabion sizes, wire gauges, mesh configurations, and coating types. This includes producing specialized box gabion units for curved structures, specific aesthetic requirements, or applications demanding exceptional load-bearing capacity. The ability to provide comprehensive technical drawings, engineering support, and on-site assistance distinguishes a true partner from a mere supplier. This level of collaboration ensures that the final product integrates seamlessly into your project design, delivering optimal performance and long-term value, reflecting a manufacturer's dedication to client satisfaction and project success.

Real-World Impact: Illustrative Application Cases

The practical utility of the gabion box is best demonstrated through its successful application in diverse real-world projects, showcasing its adaptability and reliability. For instance, in river training works, thousands of cubic meters of gabions have been deployed to stabilize riverbanks, prevent scour, and guide water flow, significantly reducing flood risks and protecting vital infrastructure. A notable case involved the rehabilitation of a major urban waterway, where the strategic placement of gabion mesh structures effectively halted embankment erosion, improving water quality and restoring riparian habitats. This project demonstrated the long-term effectiveness of gabions in dynamic hydrological environments and their role in ecological restoration.

Another compelling example involves the construction of retaining walls for highway embankments in mountainous regions. Here, steel gabions provide stable, flexible, and cost-effective solutions for slope stabilization, accommodating the natural geological movements of the terrain. One specific project in a landslide-prone area utilized a tiered gabion retaining wall system, which successfully prevented further slope failures and ensured the safety of critical transportation routes. The structures not only offered robust engineering support but also blended naturally with the mountainous landscape, demonstrating the aesthetic and environmental benefits of box gabion use in sensitive areas. These cases underscore the proven efficacy and versatile utility of gabion solutions in addressing complex engineering challenges across various scales and environments, ensuring long-term infrastructure resilience.

Ensuring Quality and Reliability: Certifications and Trust

The integrity and reliability of a gabion box are underpinned by rigorous quality assurance and adherence to international standards. Reputable manufacturers demonstrate their commitment to excellence through various certifications, which serve as benchmarks for product quality and operational efficiency. ISO 9001 certification, for instance, verifies that a company's quality management system meets globally recognized standards, ensuring consistency and continuous improvement in the manufacturing of gi gabion box products. Compliance with industry-specific standards like ASTM A975 (for steel wire gabions) and EN 10223-3 (for steel wire woven hexagonal mesh) further guarantees that the products meet stringent technical specifications for material composition, mesh integrity, and corrosion resistance, instilling confidence in their performance.

Beyond certifications, transparent testing data and authoritative citations bolster trustworthiness. This includes independent laboratory test results verifying the tensile strength of the wire, the durability of coatings (e.g., salt spray tests for galvanization and PVC), and the overall structural integrity of the assembled gabion box. Partnerships with leading engineering firms or academic institutions for R&D projects can also signify a manufacturer's dedication to innovation and quality. Publicly available client feedback and long-standing service records, often spanning decades, provide tangible evidence of consistent product performance and customer satisfaction, establishing a strong foundation of reliability and trust in the market for these critical infrastructure components.

Product Life Cycle and Sustainability

The environmental footprint and long-term sustainability of the gabion box are increasingly important considerations for modern projects. Gabion structures boast an impressive service life, often exceeding 50 years when properly designed and installed with high-quality materials and coatings. This extended longevity minimizes the need for frequent replacements, thereby reducing resource consumption and waste generated from construction activities. Furthermore, the inherent design allows for minimal disturbance to natural drainage patterns, promoting healthy ecosystems and reducing environmental impact.

Gabions contribute significantly to green infrastructure initiatives. They can be filled with locally available materials, reducing transportation costs and the associated carbon emissions. In many cases, recycled concrete or demolition debris can be used as infill, further enhancing their sustainability profile by diverting waste from landfills. The permeable nature of gabion mesh allows for vegetation growth, which helps in naturalizing the structures over time, improving aesthetics, and providing habitat for local flora and fauna. This integration with the natural environment makes the box gabion an excellent choice for ecologically sensitive projects, promoting biodiversity and enhancing landscape resilience for future generations.

Comprehensive Support and Partnership

A key differentiator for any leading supplier of gabion box products is the breadth and depth of their customer support. Beyond simply delivering products, a true partner provides end-to-end assistance, from initial consultation and design support to post-installation services. This includes detailed technical guidance on product selection, help with calculating appropriate gabion sizes, and even assistance with complex engineering drawings to ensure seamless integration into large-scale projects. Efficient logistics and a clear understanding of delivery cycles are also crucial, guaranteeing that materials arrive on time and within budget, minimizing costly delays for project stakeholders and ensuring operational continuity.

Furthermore, robust warranty provisions and accessible customer service channels build significant trust. A comprehensive warranty on gabion panels and finished units provides peace of mind regarding material defects and manufacturing faults, underscoring the manufacturer's confidence in their product quality. Responsive customer support, available to address technical queries, offer troubleshooting advice, and provide post-purchase assistance, ensures that project challenges are met with prompt and effective solutions. This commitment to continuous support and client satisfaction solidifies a long-term partnership, ensuring optimal performance and success for every project involving steel gabions, making the supplier a reliable and valued ally.

Frequently Asked Questions (FAQ) about Gabion Boxes

Q1: What is the typical lifespan of a gabion box?

A1: A well-manufactured gabion box with appropriate galvanization or PVC coating can have a service life of 30 to over 50 years, depending on environmental conditions and material quality. PVC-coated gabions offer superior longevity in highly corrosive environments.

Q2: Can gabion structures be used in marine or saltwater environments?

A2: Yes, for marine or saltwater applications, gabion mesh with heavy PVC coating over galvanization is recommended. This dual protection offers maximum resistance against the aggressive corrosive action of saltwater, ensuring the integrity of coastal defense structures and marine retaining walls.

Q3: Are gabions environmentally friendly?

A3: Absolutely. Gabions are highly sustainable. They are permeable, promote natural drainage, and allow vegetation to grow, integrating with the landscape. They can be filled with local or recycled materials, reducing transportation costs and waste, making them an eco-conscious choice for green infrastructure projects.

Q4: What are the primary advantages of woven gabions over welded gabions?

A4: Woven box gabion structures (double-twist hexagonal mesh) are more flexible and can tolerate differential settlement better without rupturing, making them ideal for unstable ground or seismic areas. Welded gabion panels, while more rigid and aesthetic, are preferred for applications requiring a precise, uniform appearance and less ground movement.

Q5: How do I determine the correct gabion sizes for my project?

A5: Selecting the right gabion sizes depends on the project's specific engineering requirements, load-bearing needs, and site conditions. Consulting with experienced geotechnical engineers or directly with the manufacturer's technical support team is highly recommended. They can provide detailed calculations and recommendations based on soil reports and structural designs.

Authoritative References and Further Reading

- ASTM A975/A975M - 19, Standard Specification for Steel Wire Gabions and Gabion Mattresses (Metallic-Coated or PVC-Coated) for Geotechnical Engineering and Erosion Control Purposes.

- EN 10223-3:2013, Steel wire and wire products for fencing and netting - Part 3: Steel wire woven hexagonal mesh products for civil engineering purposes.

- ISO 9001:2015, Quality management systems — Requirements.

- Maccaferri Gabions Technical Manuals and Design Guidelines.

- The Institution of Civil Engineers. "Geotechnical Engineering Handbook."

- Department of Transport, Highways Agency, Design Manual for Roads and Bridges (DMRB), Vol. 4, Section 1, Part 1: "Earthworks - Gabions and Reno Mattresses."

-

What is Barbed Wire Used For?

NewsAug.13,2025

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

products.