Aug . 15, 2025 03:40 Back to list

Durable Galvanized Steel Fence - Trusted Suppliers

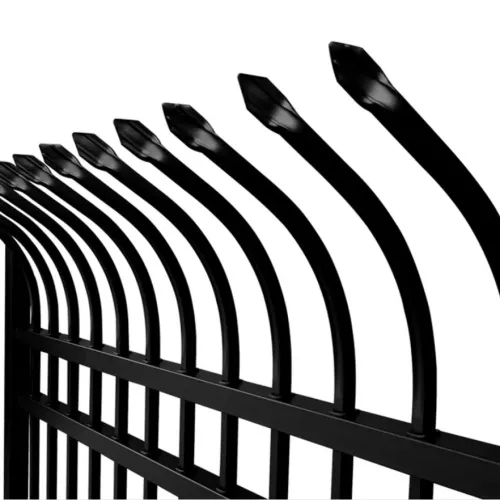

The Enduring Strength of FEN20 Galvanized Steel Fencing in Industrial & Commercial Applications

In an era where infrastructure longevity and security are paramount, the demand for robust and durable fencing solutions continues to escalate. Among the leading choices, FEN20 Galvanized Steel Fence stands out as a prime example of advanced engineering meeting critical security needs. This high-performance fencing system is specifically designed to withstand harsh environmental conditions while providing superior perimeter protection. Its exceptional corrosion resistance and structural integrity make it an invaluable asset across a multitude of sectors, ranging from petrochemical plants to public utilities, where reliability cannot be compromised. The strategic integration of advanced materials and proven manufacturing processes ensures a product life cycle that significantly surpasses conventional fencing options, delivering long-term value and peace of mind.

The industry trend is clearly shifting towards sustainable and low-maintenance solutions, driven by escalating operational costs and a global push for environmental responsibility. This is where the inherent advantages of galvanized steel, particularly the FEN20 series, become highly relevant. Its ability to resist rust and decay without frequent maintenance translates into substantial long-term cost savings and a reduced environmental footprint, aligning perfectly with modern industrial requirements. Furthermore, as security threats evolve, the robust physical barrier provided by this fencing system offers an essential layer of defense, deterring unauthorized access and protecting critical assets. The versatility in design and application further solidifies its position as a preferred choice for discerning buyers seeking both performance and durability.

Deep Dive into FEN20 Galvanized Steel Fence: Technical Specifications

The FEN20 series distinguishes itself through meticulously engineered specifications designed for optimal performance and longevity. Each component of the FEN20 Galvanized Steel Fence system is manufactured to stringent industrial standards, ensuring consistency and superior protection. The core material typically comprises high-tensile carbon steel, specifically chosen for its inherent strength and ductility, making it ideal for forming and welding processes. This material is then subjected to a hot-dip galvanization process, adhering to international standards such as ASTM A123/A123M for zinc coating thickness, which is crucial for extended corrosion resistance.

Beyond the base material and coating, precise dimensional control is paramount. This includes uniform mesh sizes, consistent wire diameters, and robust post dimensions, all contributing to the overall structural integrity and aesthetic appeal. The design considers factors like wind load resistance and impact absorption, ensuring the fence maintains its form and function even under challenging conditions. Such detailed engineering ensures that the FEN20 Galvanized Steel Fence is not merely a barrier but a reliable security solution built to last for decades, minimizing the total cost of ownership over its service life.

FEN20 Galvanized Steel Fence Typical Specifications

| Parameter | Typical Specification (FEN20 Series) | Relevant Standard/Note |

|---|---|---|

| Material Grade | Low Carbon Steel (e.g., Q195, Q235) | ASTM A510 / EN 10025 |

| Wire Diameter (mm) | 3.0mm - 6.0mm | Varies by panel strength requirement |

| Mesh Opening (mm) | 50x100mm, 50x200mm, 75x150mm | Security and visibility balance |

| Fence Height (m) | 1.2m - 3.0m (customizable) | Adaptable to application needs |

| Fence Length (m) | 2.0m - 3.0m per panel | Standard panel dimensions |

| Zinc Coating Thickness (g/m²) | Min. 60 g/m² (Commercial Grade) up to 275 g/m² (Heavy Duty) | ISO 1461 / ASTM A123/A123M for hot-dip galvanizing |

| Surface Treatment | Hot-dip Galvanized, often with Polyester Powder Coating | Enhances aesthetics and corrosion resistance |

| Tensile Strength | Typically 500-700 MPa | Ensures structural integrity |

The Manufacturing Mastery: Crafting the FEN20 Galvanized Steel Fence

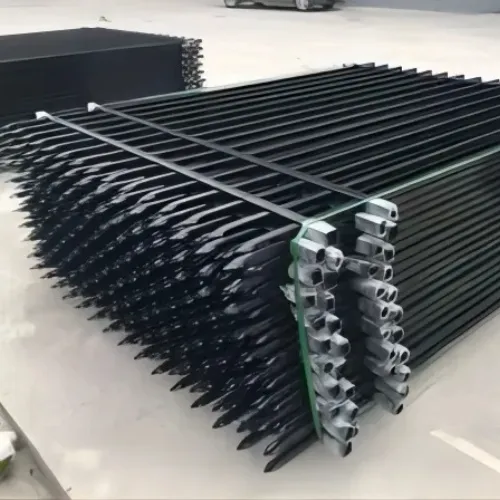

The production of a high-quality FEN20 Galvanized Steel Fence involves a precise, multi-stage manufacturing process designed to maximize durability and performance. It commences with the selection of premium low-carbon steel wire rods, which are rigorously inspected for metallurgical consistency and surface defects. These rods are then drawn to the specified wire diameters, ensuring uniform tensile strength throughout the batch. The formation of the fence panels follows, typically involving automated welding techniques where horizontal and vertical wires are resistance-welded at their intersections, creating a rigid and coherent mesh structure. This welding process is meticulously controlled to prevent weak points and ensure maximum joint strength, crucial for the fence's integrity.

The critical stage for the longevity of the FEN20 Galvanized Steel Fence is the hot-dip galvanization. Prior to immersion in molten zinc, the fabricated panels undergo a thorough cleaning regimen: degreasing to remove oils and greases, pickling in acid to eliminate mill scale and rust, and then fluxing to prepare the steel surface for optimal zinc adhesion. The panels are then submerged in a bath of molten zinc at approximately 450°C (840°F). During this immersion, a metallurgical reaction occurs, forming a series of zinc-iron alloy layers that are metallurgically bonded to the steel surface, followed by an outer layer of pure zinc. This creates an incredibly durable, sacrificial coating that protects the steel from corrosion even if the outer layer is scratched. Post-galvanization, panels are inspected for coating thickness, uniformity, and adhesion, often tested against international standards such as ISO 1461 and ANSI/AWWA C104/A21.4. This comprehensive process, far from simple casting or forging, ensures the exceptional anti-corrosion properties and extended service life applicable in sectors like petrochemical and water treatment, where constant exposure to corrosive elements is common.

Unrivaled Technical Advantages and Performance Benefits

The technical prowess of FEN20 Galvanized Steel Fence systems translates directly into significant advantages for industrial and commercial users. Primarily, its superior corrosion resistance, achieved through the hot-dip galvanization process, provides a protective barrier against rust and environmental degradation. This inherent resistance makes it exceptionally well-suited for deployment in harsh climates, coastal regions, and industrial zones exposed to chemicals or high humidity, delivering a service life of 20-50 years, significantly longer than untreated or superficially coated steel. This extended lifespan directly contributes to reduced replacement cycles, offering substantial long-term cost savings on maintenance and capital expenditure.

Furthermore, the robust construction of the FEN20 Galvanized Steel Fence ensures high structural integrity and resistance to physical impact. The high tensile strength of the steel, combined with the rigid mesh design, makes it an effective deterrent against unauthorized entry and vandalism. Its low maintenance profile is another key benefit; unlike painted or less durable fencing, galvanized steel requires minimal upkeep, eliminating the need for frequent repainting or rust treatment, thus freeing up maintenance budgets. This combination of durability, low maintenance, and high security makes it an economically sound and strategically advantageous choice for critical infrastructure, including facilities in the oil & gas, power generation, and transportation sectors, contributing indirectly to operational efficiency and safety through reliable perimeter security and protection.

Versatile Application Scenarios & Proven Case Studies

The adaptability and robust nature of the FEN20 Galvanized Steel Fence make it an ideal solution for a diverse range of application scenarios across various industries. In the petrochemical sector, it provides secure perimeter fencing for refineries, chemical plants, and storage facilities, effectively containing sensitive areas and preventing unauthorized access in potentially hazardous environments. Similarly, within the metallurgy industry, it secures valuable raw materials and finished goods, while providing safety barriers around heavy machinery and operational zones. For water and wastewater treatment plants, its corrosion resistance is particularly beneficial, standing up to constant moisture and chemical exposure, ensuring the security of critical public infrastructure.

Beyond these specific industries, the FEN20 Galvanized Steel Fence finds extensive use in protecting data centers, power stations, airports, military bases, and logistics hubs. Its modular design allows for rapid deployment and integration with advanced security systems like CCTV and access control. For instance, in a recent project for a major European railway network, over 10 kilometers of FEN20 fencing were installed along critical tracks, significantly reducing unauthorized access and enhancing operational safety. Another notable application involved securing a large-scale solar farm in a desert environment, where the fence’s ability to withstand extreme temperatures and sand abrasion was paramount, showcasing its resilience and long-term reliability in challenging conditions. These real-world applications underscore its versatility and proven performance.

Selecting Your Partner: Identifying Reputable Galvanized Steel Fence Suppliers

Choosing the right partner among galvanized steel fence suppliers is as crucial as selecting the product itself. A reputable supplier should demonstrate not only expertise in manufacturing but also a deep understanding of industry standards, project management capabilities, and unwavering commitment to quality. Key indicators of a reliable supplier include adherence to international certifications like ISO 9001 for quality management and ISO 14001 for environmental management. Such certifications signify a dedication to consistent product quality and responsible manufacturing practices. Furthermore, look for suppliers with a strong track record, substantial service years in the industry, and positive client testimonials, especially from large-scale B2B projects.

Beyond certifications, assess their capacity for customization, technical support, and post-sales service. Top-tier galvanized steel fence suppliers should be able to offer tailored solutions that meet specific project requirements, whether it's specialized dimensions, additional coatings, or integrated security features. Their ability to provide detailed engineering drawings, installation guides, and prompt customer support is indicative of a reliable partnership. A transparent delivery schedule and clear warranty terms also build trust, ensuring that your investment is protected and your project timelines are met. The table below outlines critical factors for evaluating potential suppliers, helping you make an informed decision for your FEN20 project.

Supplier Comparison Criteria

| Criterion | Description & Importance |

|---|---|

| Certifications & Standards Adherence | ISO 9001 (Quality), ISO 14001 (Environment), ASTM, EN standards. Ensures consistent quality and compliance. |

| Customization Capabilities | Ability to produce FEN20 galvanized steel fence in custom heights, lengths, mesh sizes, and colors. Crucial for unique project requirements. |

| Manufacturing Process Transparency | Openness about material sourcing, welding techniques, and galvanization methods. Indicates quality control and reliability. |

| Lead Times & Logistics | Reliable production and delivery schedules. Efficient logistics network for timely project completion. |

| Technical Support & After-Sales Service | Availability of engineers for consultation, installation guidance, and responsive post-delivery support. |

| Warranty & Guarantees | Clear and comprehensive warranty terms on coating performance and structural integrity. Essential for long-term assurance. |

Tailored Solutions and Streamlined Delivery Protocols

Recognizing that every industrial or commercial project has unique requirements, leading galvanized steel fence suppliers offer comprehensive customization options for their FEN20 Galvanized Steel Fence systems. This includes precise tailoring of fence height, panel length, wire diameter, and mesh aperture to meet specific security levels and aesthetic preferences. Beyond standard dimensions, clients can often specify additional surface treatments, such as PVC or polyester powder coating over the galvanization, available in a wide spectrum of RAL colors. This dual-layer protection not only enhances visual appeal but also provides an extra shield against UV radiation and chemical exposure, further extending the fence's lifespan in demanding environments. Security enhancements like barbed wire, razor wire, or integrated sensor systems can also be incorporated during the design phase.

Efficient delivery and logistics are paramount for large-scale B2B projects. Reputable suppliers implement robust protocols to ensure timely and secure transportation of the FEN20 Galvanized Steel Fence components. This includes careful packaging to prevent damage during transit, utilizing durable wooden pallets or steel frames. Typical lead times for standard orders range from 3-5 weeks, though this can vary based on order volume, customization complexity, and current production schedules. For international shipments, suppliers manage all necessary documentation, customs clearance, and freight forwarding, providing clients with comprehensive tracking and communication throughout the entire process. This meticulous approach ensures that projects stay on schedule and materials arrive in pristine condition, ready for immediate installation.

Commitment to Quality Assurance and Comprehensive Warranty

Quality assurance is a cornerstone in the production of every FEN20 Galvanized Steel Fence. From the initial sourcing of raw materials to the final inspection of finished panels, a multi-stage quality control process is rigorously applied. This begins with material verification, ensuring that steel grades meet specified metallurgical compositions and mechanical properties. During fabrication, welding integrity is continuously monitored using non-destructive testing methods. Post-galvanization, each batch undergoes meticulous inspection for zinc coating thickness and adhesion, often using magnetic or eddy current gauges, and adherence to ISO 1461 standards. Visual inspections identify any surface imperfections, ensuring a flawless finish. Our commitment extends to periodic third-party audits to validate our internal quality systems, providing an unbiased assessment of our production excellence.

To underscore our confidence in the durability and performance of our FEN20 Galvanized Steel Fence products, we offer comprehensive warranty programs. Typically, our hot-dip galvanized fences come with a warranty covering zinc coating performance against red rust for 10 to 25 years, depending on the environment and coating thickness. Structural integrity warranties often extend even longer, covering manufacturing defects that might compromise the fence's physical stability. Our dedicated customer support team is available to assist with any queries, from technical specifications to warranty claims, ensuring peace of mind for our clients throughout the product's extensive service life. This unwavering commitment to quality and support reflects our standing as a trusted partner among galvanized steel fence suppliers.

Frequently Asked Questions (FAQ) about FEN20 Galvanized Steel Fence

Q1: What is the expected lifespan of a FEN20 Galvanized Steel Fence?

A1: With proper installation and in typical environments, a FEN20 Galvanized Steel Fence can last anywhere from 20 to 50 years, largely due to the robust hot-dip galvanization that provides superior corrosion resistance. In less corrosive environments, its lifespan can exceed 50 years. The addition of a polyester powder coating can further extend this duration and enhance aesthetic longevity.

Q2: Is the FEN20 Galvanized Steel Fence suitable for harsh coastal environments?

A2: Absolutely. The thick zinc coating applied during the hot-dip galvanization process provides excellent protection against salt spray and humid conditions prevalent in coastal areas. For extreme coastal or industrial settings, we recommend higher zinc coating thicknesses (e.g., 275 g/m²) or an additional powder coating for enhanced durability against corrosive elements.

Q3: How difficult is the installation of FEN20 Galvanized Steel Fence?

A3: The FEN20 system is designed for relatively straightforward installation, particularly the modular panel systems. While professional installation is recommended for optimal security and longevity, the system's design minimizes complex procedures. Suppliers often provide detailed installation guides and technical support to ensure a smooth setup process.

Q4: Can the FEN20 Galvanized Steel Fence be customized for specific security needs?

A4: Yes, extensive customization options are available. This includes varying panel heights, wire diameters for increased strength, mesh sizes for anti-climb features, and the integration of security toppings like barbed wire, razor wire, or specialized security systems. Our team works closely with clients to design bespoke solutions that meet precise security requirements.

Q5: What maintenance is required for a FEN20 Galvanized Steel Fence?

A5: One of the significant advantages of hot-dip galvanized steel fencing is its low maintenance. Unlike painted fences, it doesn't require regular repainting. Periodic inspection for physical damage or accumulated debris is generally sufficient. Any significant damage to the zinc coating should be promptly addressed to maintain the fence's protective integrity.

Conclusion: The Definitive Choice for Durable Perimeter Security

The FEN20 Galvanized Steel Fence represents the pinnacle of perimeter security solutions, engineered to deliver unparalleled durability, exceptional corrosion resistance, and robust physical protection for a wide array of industrial and commercial applications. Its meticulously controlled manufacturing process, from high-grade steel selection to the advanced hot-dip galvanization, ensures a product that withstands the test of time and environmental adversities. This commitment to quality translates into significant long-term savings through reduced maintenance and replacement costs, making it a highly cost-effective investment over its extended service life.

For businesses and critical infrastructure operators seeking reliable and resilient fencing solutions, the FEN20 series offers a definitive answer. Its adaptability to diverse environments, combined with comprehensive customization options and a strong emphasis on post-sales support, solidifies its position as a leading choice among discerning buyers and top-tier galvanized steel fence suppliers. Investing in a FEN20 Galvanized Steel Fence is not merely purchasing a barrier; it's securing an enduring asset that guarantees peace of mind and operational continuity for decades to come.

References:

- American Society for Testing and Materials (ASTM) Standards for Hot-Dip Galvanizing, A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- International Organization for Standardization (ISO) 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- NACE International (formerly National Association of Corrosion Engineers) Publications on Corrosion Protection and Materials Performance.

- Galvanizers Association, Technical Notes on the Durability and Maintenance of Hot Dip Galvanized Coatings.

- European Committee for Standardization (CEN) EN 10025 series: Hot rolled products of structural steels.

-

What is Barbed Wire Used For?

NewsAug.13,2025

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

products.