Mar . 05, 2025 01:22 Back to list

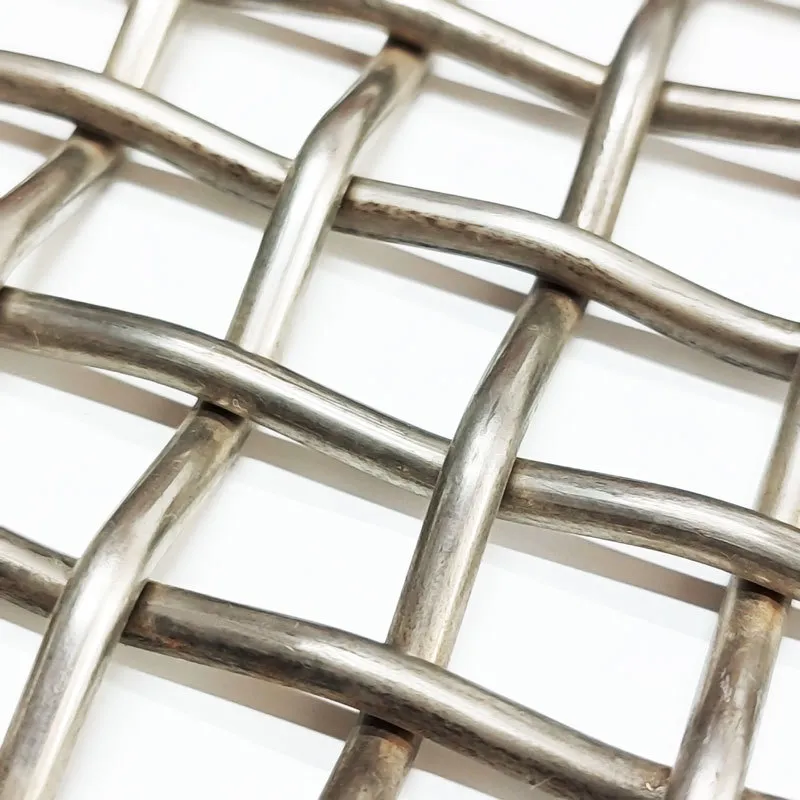

external render reinforcing mesh

External render reinforcing mesh is a vital component in the construction and renovation industry, enhancing the durability and lifespan of external rendering systems. When applied correctly, it acts as a backbone for render layers, preventing cracking and ensuring the render retains its aesthetic appeal over time. This article delves into the in-depth applications and benefits of using reinforcing mesh in external rendering projects, supported by expert recommendations and insights rooted in practical experience.

Practical application experience highlights a few best practices in reinforcing mesh deployment. One critical step is ensuring the substrate is clean and primed appropriately before application to facilitate maximum adhesion. Proper overlap and integration of mesh panels are also vital, with industry experts advocating for a minimum of 10cm overlap to prevent seam failure. Additionally, embedding the mesh within the preferred render layer using a trowel must be executed with precision, eliminating wrinkles or bubbles that could compromise structural integrity. Employing trained professionals for this phase is often recommended to maintain the expertise and quality assurance standards required for durable outcomes. From a trustworthiness perspective, choosing quality-assured reinforcing mesh from reputable manufacturers ensures compliance with building regulations and standards. Products should be tested and endorsed by industry-recognized bodies, providing peace of mind for specifiers and end users alike. As sustainability becomes a key consideration in building material selection, the eco-friendliness of mesh products—such as their recyclability and manufacturing footprint—should also be evaluated. In conclusion, external render reinforcing mesh embodies a blend of strength, flexibility, and resilience, transforming the long-term performance of render systems. It is crucial for professionals involved in building construction and renovation projects to recognize its value, ensuring it is effectively integrated as part of an overall strategy for enhancing building aesthetics and functionality. With the right expertise, authoritative guidance, and product trustworthiness, leveraging reinforcing mesh can significantly contribute to creating buildings that stand firm against the challenges posed by time and nature.

Practical application experience highlights a few best practices in reinforcing mesh deployment. One critical step is ensuring the substrate is clean and primed appropriately before application to facilitate maximum adhesion. Proper overlap and integration of mesh panels are also vital, with industry experts advocating for a minimum of 10cm overlap to prevent seam failure. Additionally, embedding the mesh within the preferred render layer using a trowel must be executed with precision, eliminating wrinkles or bubbles that could compromise structural integrity. Employing trained professionals for this phase is often recommended to maintain the expertise and quality assurance standards required for durable outcomes. From a trustworthiness perspective, choosing quality-assured reinforcing mesh from reputable manufacturers ensures compliance with building regulations and standards. Products should be tested and endorsed by industry-recognized bodies, providing peace of mind for specifiers and end users alike. As sustainability becomes a key consideration in building material selection, the eco-friendliness of mesh products—such as their recyclability and manufacturing footprint—should also be evaluated. In conclusion, external render reinforcing mesh embodies a blend of strength, flexibility, and resilience, transforming the long-term performance of render systems. It is crucial for professionals involved in building construction and renovation projects to recognize its value, ensuring it is effectively integrated as part of an overall strategy for enhancing building aesthetics and functionality. With the right expertise, authoritative guidance, and product trustworthiness, leveraging reinforcing mesh can significantly contribute to creating buildings that stand firm against the challenges posed by time and nature.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.