Nov . 20, 2024 06:19 Back to list

f72 mesh cost

The Cost Analysis of F72% Mesh in Various Applications

In recent years, the demand for high-quality mesh materials has surged across various industries. One such material that has garnered attention is the F72% mesh, known for its durability, versatility, and cost-effectiveness. In this article, we will explore the factors influencing the cost of F72% mesh and its applications in different sectors.

Understanding F72% Mesh

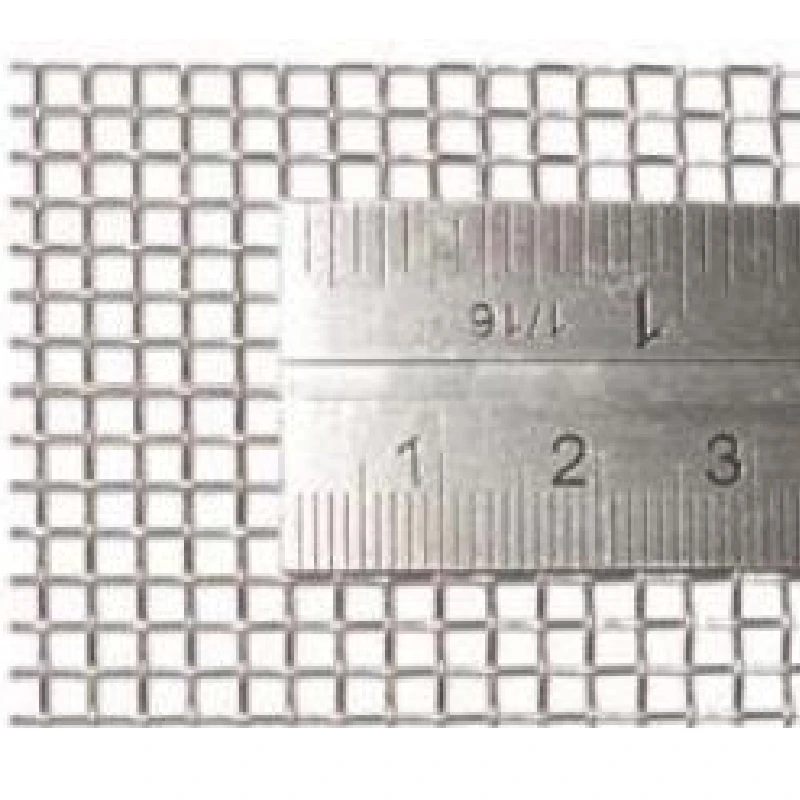

F72% mesh refers to a specific type of mesh with 72% open area, which is achieved through a particular weaving technique. This open area ratio makes it ideal for applications requiring high airflow, filtration, and drainage. Typically composed of synthetic fibers or metals, this mesh is used in construction, agriculture, manufacturing, and other related fields.

Factors Influencing Cost

1. Material Composition The primary factor affecting the cost of F72% mesh is the type of material used. Synthetic materials tend to be less expensive than metals. For instance, polyester or polypropylene meshes are often more cost-effective compared to stainless steel or aluminum variants. The choice of material will greatly influence the price, as well as the durability and performance of the mesh in various applications.

2. Manufacturing Process The method through which the F72% mesh is fabricated can also impact its cost. Techniques such as weaving, welding, or knitting can have different cost implications. Weaving, for example, may require more advanced machinery and skilled labor, which can increase the overall manufacturing costs. Conversely, automated processes might reduce costs but could lead to variations in quality.

3. Mesh Specifications The specifications of the F72% mesh, including its thickness, width, and thread count, also play a critical role in determining its cost. Thicker meshes or those with a higher thread count typically command a higher price due to the greater amount of material used and the increased complexity of production.

4. Market Demand and Supply Like any other product, the market dynamics of supply and demand will affect the pricing of F72% mesh. In times of high demand, prices may surge, depending on how quickly manufacturers can respond to market needs. Conversely, during periods of low demand, prices may stabilize or even decrease.

f72 mesh cost

5. Shipping and Handling The cost of shipping and handling should not be overlooked. F72% mesh can be bulky, and transportation costs can add up, particularly for large orders. Additionally, if the mesh is imported from a different country, tariffs and import duties can further inflate its price.

Applications of F72% Mesh

The versatility of F72% mesh makes it suitable for a range of applications, which also informs its pricing structure. Below are some key sectors where F72% mesh is commonly utilized

- Construction In construction, F72% mesh is often used for reinforcement in concrete applications, providing essential structural support while optimizing drainage. Its cost-effectiveness makes it a preferred choice for many contractors looking to stay within budget while ensuring safety and reliability.

- Agriculture Farmers utilize F72% mesh for various purposes, including fencing, shade cloths, and soil stabilization. Its breathable nature allows for effective water drainage while also protecting crops from pests. The affordability of F72% mesh can significantly impact a farmer's operational costs.

- Manufacturing In manufacturing, F72% mesh serves as a filtration medium and is essential in various processes, including powder coating and pharmaceutical production. The cost of mesh directly affects the overall production costs, making it crucial for manufacturers to choose wisely.

Conclusion

In conclusion, the cost of F72% mesh is determined by a myriad of factors, including material composition, manufacturing processes, specifications, market dynamics, and shipping costs. Its wide-ranging applications in construction, agriculture, and manufacturing highlight its importance across sectors. As industries continue to evolve and demand for high-quality mesh grows, understanding these cost components will become increasingly vital for consumers and manufacturers alike. Ultimately, investing in F72% mesh can yield significant benefits, provided that one carefully considers these various factors before making a purchase.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.