Mar . 05, 2025 02:53 Back to list

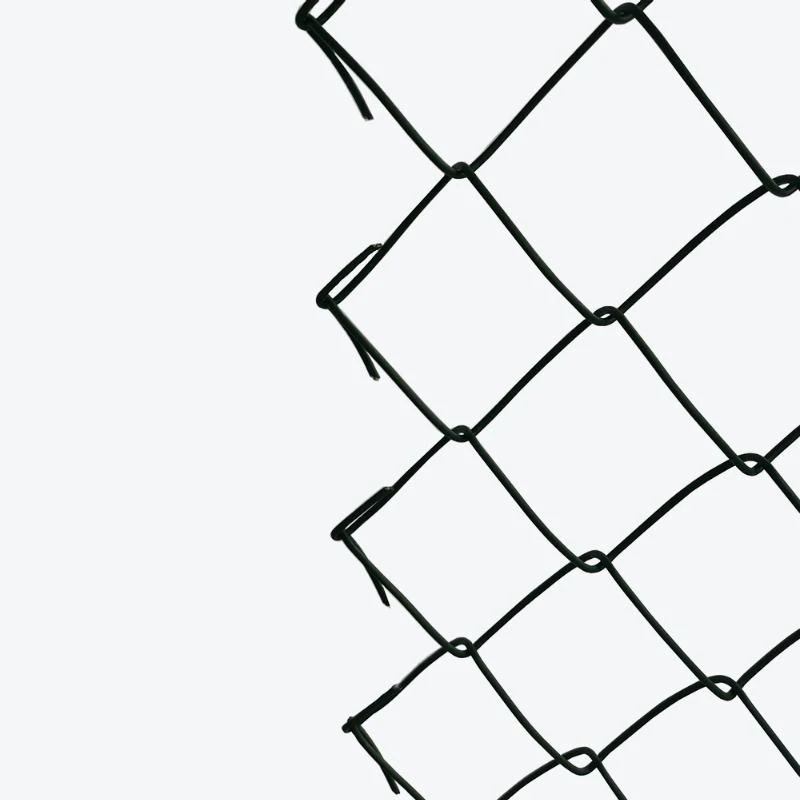

floor screed mesh

Floor screed mesh is a crucial component in the construction and renovation industries, especially when aiming to enhance the durability and stability of floor surfaces. This product, when used effectively, contributes significantly to the longevity and performance of screeded floors. A deep understanding of its applications, benefits, and installation techniques can affirm one's expertise in the field and instill trust among clients and colleagues alike.

Installation techniques significantly impact the performance of the floor screed mesh. A common pitfall is failing to ensure that the mesh is adequately supported and fully encapsulated in the screed. This can lead to the mesh failing to perform its reinforcing role effectively. Proper practice involves using spacers to lift the mesh off the substrate before screeding begins, ensuring that it sits in the correct position within the screed layer. Further enhancing installation quality involves the precise calculation of screed depth and mesh size. Industry best practices dictate a balance that accommodates the specific load-bearing requirements of the floor while optimizing the use of materials. For instance, incorrect screed thickness could compromise the structural contributions of the mesh or lead to unnecessary resource expenditure. The adoption of advanced techniques and materials in the preparation of screed mixes, employing additives for strength enhancement, and improvements in mixing and curing processes further cement the authority and trust professionals command in the use of floor screed mesh. Considering the essential role of floor screed mesh, professionals are continually seeking innovative solutions and advancements in product technology that improve installation efficiency and floor performance. The future of floor screeding lies in embracing these technological improvements, utilizing smart materials that provide even greater resilience and adaptability to changing environmental conditions. In conclusion, floor screed mesh demonstrates unparalleled importance in creating durable, high-performance flooring systems. Mastery in its applications, steeped in evidence-backed experience and professional know-how, establishes a reputation for excellence and reliability in the construction industry. By embracing continuous learning about product advancements and maintaining rigorous standards in installation, industry professionals can significantly enhance floor longevity, reflecting positively on their technical and professional acumen.

Installation techniques significantly impact the performance of the floor screed mesh. A common pitfall is failing to ensure that the mesh is adequately supported and fully encapsulated in the screed. This can lead to the mesh failing to perform its reinforcing role effectively. Proper practice involves using spacers to lift the mesh off the substrate before screeding begins, ensuring that it sits in the correct position within the screed layer. Further enhancing installation quality involves the precise calculation of screed depth and mesh size. Industry best practices dictate a balance that accommodates the specific load-bearing requirements of the floor while optimizing the use of materials. For instance, incorrect screed thickness could compromise the structural contributions of the mesh or lead to unnecessary resource expenditure. The adoption of advanced techniques and materials in the preparation of screed mixes, employing additives for strength enhancement, and improvements in mixing and curing processes further cement the authority and trust professionals command in the use of floor screed mesh. Considering the essential role of floor screed mesh, professionals are continually seeking innovative solutions and advancements in product technology that improve installation efficiency and floor performance. The future of floor screeding lies in embracing these technological improvements, utilizing smart materials that provide even greater resilience and adaptability to changing environmental conditions. In conclusion, floor screed mesh demonstrates unparalleled importance in creating durable, high-performance flooring systems. Mastery in its applications, steeped in evidence-backed experience and professional know-how, establishes a reputation for excellence and reliability in the construction industry. By embracing continuous learning about product advancements and maintaining rigorous standards in installation, industry professionals can significantly enhance floor longevity, reflecting positively on their technical and professional acumen.

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.