Nov . 19, 2024 02:20 Back to list

gabion wire mesh specification

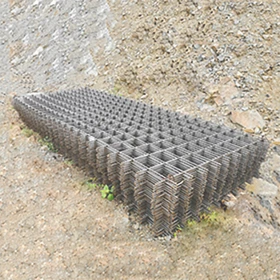

Understanding Gabion Wire Mesh Specifications

Gabion wire mesh structures have become a popular choice in civil engineering, landscaping, and environmental management due to their versatility and durability. These structures are made of wire mesh filled with stones, earth, or other materials to form walls, barriers, and decorative features. To ensure the effectiveness and longevity of gabion systems, understanding the specifications of gabion wire mesh is crucial.

1. Material Composition

The primary materials used in gabion wire mesh are typically steel wire or other corrosion-resistant materials. The wire is usually galvanized to protect against rust and degradation, which is essential for structures exposed to natural elements. The specifications often include a minimum zinc coating thickness, which is measured in grams per square meter (g/m²). Higher zinc coating thickness increases the lifespan of the gabion, especially in humid or corrosive environments.

2. Wire Diameter

The diameter of the wire used in gabion mesh is a critical factor that determines the strength and durability of the gabion structure. Common wire diameters range from 2.0 mm to 4.0 mm. Thicker wires provide greater tensile strength, making them suitable for high-stress applications, such as riverbank stabilization projects. Conversely, thinner wires may be sufficient for less demanding applications, such as decorative garden walls.

3. Mesh Opening Size

The size of the mesh openings is another vital specification. Gabion meshes are often constructed with various opening sizes, typically ranging from 60 mm x 80 mm to 100 mm x 100 mm. The choice of mesh opening size depends on the fill material used and the specific project requirements. Smaller openings help to retain finer materials and improve the stability of the structures, while larger openings may allow for faster drainage and improve overall performance.

gabion wire mesh specification

Gabion wire mesh comes in different configurations, including single and double twist styles. The single twist configuration combines adjacent wires to form a sturdy mesh, while the double twist configuration further enhances stability and reduces the risk of unraveling under tension. Specifications will often outline the particular configuration to be used, depending on the application.

5. Tensile Strength and Load Capacity

Specifications typically include the tensile strength of the wire, which is crucial for determining how much load the gabion can bear. The tensile strength is usually expressed in megapascals (MPa) and is influenced by the wire diameter and material properties. In general, higher tensile strength equates to better performance under heavy loads, making it essential for projects involving structural integrity.

6. Environmental Considerations

When selecting gabion wire mesh, environmental factors must also be considered. Mesh that is resistant to corrosion is preferable in areas subject to moisture or chemical exposure. Additionally, some specifications might include environmental standards that align with green building practices, ensuring that materials used are sustainable and have minimal environmental impact.

7. Quality Assurance

To ensure that the gabion wire mesh meets the required specifications, quality assurance measures are essential. Manufacturers often partake in testing processes to verify that their products adhere to industry standards. This may include assessments of mechanical properties, such as tensile strength, and resistance to environmental degradation. Certification from recognized standards organizations can provide additional assurance of quality.

Conclusion

In conclusion, understanding gabion wire mesh specifications is vital for anyone involved in the design or construction of gabion structures. Key factors such as material composition, wire diameter, mesh opening size, structural configuration, tensile strength, environmental considerations, and quality assurance all play critical roles in ensuring the durability and effectiveness of gabion systems. By carefully selecting materials and adhering to specifications, builders can create robust and sustainable structures that stand the test of time.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.