Dec . 25, 2024 05:35 Back to list

Wire for galvanized after welding applications and its importance in construction industries

The Importance of Galvanized After Weld (GAW) Wire in Modern Construction and Manufacturing

In the realm of construction and manufacturing, steel and its various forms play pivotal roles in ensuring the durability and longevity of structures and products. One specific type of wire that has garnered attention for its unique properties is galvanized after weld (GAW) wire. This specialized wire is designed to withstand the challenges posed by environmental factors and mechanical stress, making it an invaluable asset across numerous industries.

Understanding GAW Wire

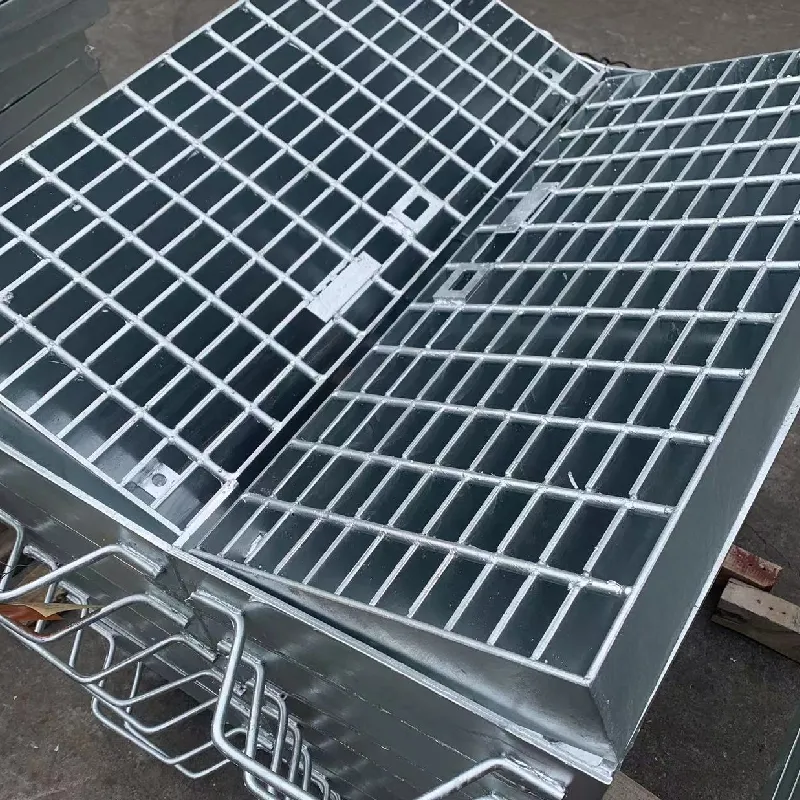

Galvanized after weld wire refers to steel wire that has undergone a galvanization process post-welding. Galvanization involves coating the steel with a layer of zinc, which serves as a protective barrier against rust and corrosion. The after weld aspect indicates that the galvanization occurs after the wire has been welded, ensuring that the welded joints are also protected. This is a key distinction that elevates GAW wire above conventional galvanized options, which may not adequately shield welded areas.

Benefits of GAW Wire

1. Corrosion Resistance The most significant advantage of GAW wire is its enhanced resistance to corrosion. In environments that are prone to humidity, rain, or exposure to chemicals, untreated steel wires can succumb to rust, leading to structural compromise. GAW wire mitigates this risk by providing a robust zinc coating that protects the underlying steel, ensuring that the wire maintains its integrity over time.

2. Longevity Structures utilizing GAW wire exhibit a longer lifespan due to the protective qualities of galvanization. By preventing corrosion, GAW wire reduces the need for frequent replacements or repairs, ultimately saving time and resources for manufacturers and builders alike.

galvanized after weld wire

3. Mechanical Strength GAW wire is not only resistant to environmental factors but also exhibits excellent mechanical properties. The welding process used prior to galvanization ensures that the wire retains sufficient flexibility and strength, which is crucial for applications requiring load-bearing capabilities.

4. Versatility in Applications This type of wire is incredibly versatile, finding utility in various domains including construction, agriculture, fencing, and even in the manufacturing of automotive parts. GAW wire is commonly used in the production of welded wire fences, reinforcement meshes for concrete, and in creating durable agricultural enclosures.

5. Cost-Efficiency Although the initial cost of GAW wire might be higher than that of untreated wire, the long-term savings associated with reduced maintenance and replacement costs make it a cost-effective choice. Building materials that last longer with less upkeep ultimately contribute to lower overall project expenses.

Challenges and Considerations

While GAW wire offers numerous benefits, there are some factors to consider when selecting it for specific projects. Installation techniques and welding methods can affect its performance. Proper training and awareness about the handling of GAW wire are crucial for ensuring that its protective qualities are maximized and that no damage occurs during the installation process.

Conclusion

In conclusion, galvanized after weld wire stands as a testament to the advancements in material science and engineering. Its ability to resist corrosion, coupled with superior mechanical strength and versatility, positions it as an essential component in the construction and manufacturing industries. As the demand for durable, long-lasting materials continues to grow, GAW wire is likely to play an increasingly central role, helping to shape the future of building and fabrication. For those involved in projects requiring dependable performance and longevity, investing in GAW wire is a prudent choice that promises enduring results.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.