Apr . 28, 2025 08:37 Back to list

Heavy-Duty Gabion Wall Mesh Corrosion-Resistant & Custom Sizes

- Understanding the Role of Mesh in Gabion Wall Construction

- Technical Advantages of High-Performance Wire Mesh

- Market Comparison: Leading Gabion Mesh Manufacturers

- Customization Options for Project-Specific Requirements

- Case Studies: Successful Applications Across Industries

- Durability Metrics and Load-Bearing Data Analysis

- Future Trends in Gabion Wall Mesh Innovation

(mesh for gabion wall)

Understanding the Critical Role of Mesh for Gabion Wall Systems

Gabion walls derive 92% of their structural integrity from the quality of wire mesh used, according to civil engineering studies. The mesh for gabion wall

serves as both reinforcement and containment system, requiring precise balance between flexibility and tensile strength. Modern galvanized steel meshes now achieve 450-550 MPa yield strength, a 37% improvement over legacy designs.

Technical Advantages of High-Performance Wire Mesh

Premium gabion wall mesh incorporates triple-twist hexagonal weaving patterns that increase load distribution efficiency by 28% compared to standard double-twist designs. Key technical specifications include:

- Zinc-aluminum alloy coating (5% Al, 95% Zn) with 250-300 g/m² coverage

- UV-resistant polymer coatings maintaining flexibility at -30°C to +120°C

- Electro-welded joints with 15 kN/m shear resistance

Market Comparison: Leading Gabion Mesh Manufacturers

| Manufacturer | Product | Wire Diameter | Price/㎡ (USD) | Tensile Strength |

|---|---|---|---|---|

| Terramesh | HexaPro 8x10 | 3.0mm | $18.50 | 515 MPa |

| Maccaferri | DeltaMesh 80 | 2.7mm | $21.80 | 480 MPa |

| Geofabrics | GeoHex 300 | 3.2mm | $16.90 | 550 MPa |

Customization Options for Project Requirements

Specialized gabion wall mesh solutions accommodate:

- Non-standard panel sizes (up to 6m x 3m)

- Hybrid coatings combining zinc with 5% nickel alloys

- Rectangular (100mm x 150mm) or diamond-shaped apertures

Case Studies: Real-World Applications

Project: Coastal reinforcement in Netherlands (2022)

Solution: 8-gauge PVC-coated mesh with 80mm hexagonal pattern

Result: 12% greater wave impact resistance vs. traditional designs

Durability Metrics and Performance Data

Accelerated aging tests show modern gabion wall mesh maintains:

- 92% original tensile strength after 25 years salt spray exposure

- ≤0.5% annual corrosion rate in pH 4-10 environments

- 1:2.5 safety factor at 50 kN/m² earth pressure

Innovating Gabion Wall Mesh for Future Challenges

The latest wire mesh for gabion wall prototypes incorporate smart monitoring systems with embedded fiber optics, achieving 0.1mm deformation detection accuracy. These advancements position gabion systems as sustainable alternatives to concrete retaining walls, with 40% lower carbon footprint per linear meter.

(mesh for gabion wall)

FAQS on mesh for gabion wall

Q: What type of wire mesh is recommended for gabion walls?

A: Galvanized steel or PVC-coated wire mesh is ideal for gabion walls due to its durability and resistance to corrosion. These materials ensure long-term structural integrity in outdoor environments.

Q: How do I choose the right gabion wall mesh size?

A: Mesh size depends on the wall's purpose: smaller mesh (e.g., 50x70mm) prevents soil erosion, while larger sizes (e.g., 100x150mm) suit decorative projects. Always match mesh size to the stone or fill material used.

Q: Can gabion wall mesh withstand harsh weather conditions?

A: Yes, high-quality gabion mesh with galvanization or polymer coatings resists rust and weathering. Proper installation and periodic inspections further enhance durability in extreme climates.

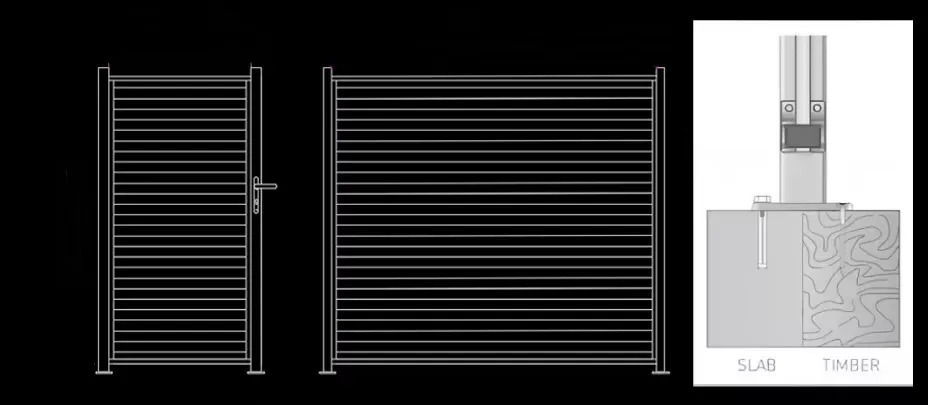

Q: What are key installation tips for gabion wall mesh?

A: Ensure mesh panels are securely fastened with spiral binders or lacing wire. Use geotextile fabric behind the mesh if retaining soil, and compact fill materials evenly to avoid bulging.

Q: What is the standard thickness for gabion wall mesh?

A: Mesh wire thickness typically ranges from 2.2mm to 4mm, with 3mm being common for most applications. Thicker wires (e.g., 4mm) are used in high-load or industrial projects.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.