Mar . 06, 2025 12:18 Back to list

mesh for concrete wall

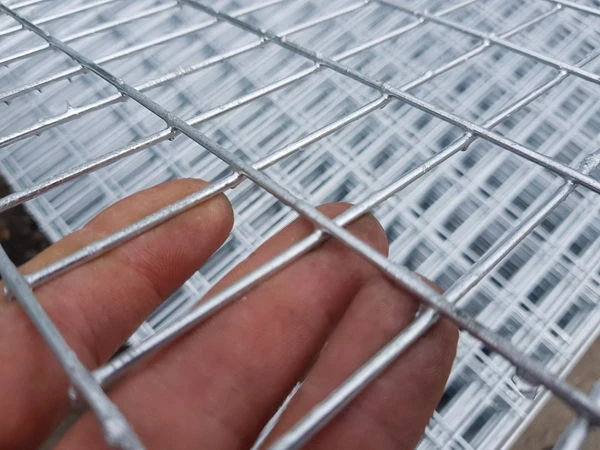

The integration of mesh within concrete wall structures has become a pivotal advancement in construction, offering unmatched durability and structural integrity. Mesh, often made from steel or synthetic materials, acts as reinforcement, ensuring that the concrete can withstand greater stresses and loads without compromise. This article delves into the pressing reasons why using mesh in concrete walls is not only a suggestion but a necessity for modern constructions.

Moreover, the process of embedding mesh within concrete is straightforward when done by skilled workers. Precision in this process is essential, as the mesh must be adequately supported and positioned before and during the concrete pour to ensure effective load distribution and structural integrity. Oversight by civil engineers or experienced technicians ensures that the framework is adequately supported until the concrete cures and consolidates the mesh within its matrix. Authoritative construction codes and guidelines underline the necessity of using reinforced mesh to meet or exceed safety standards. These standards ensure that buildings can withstand natural disasters such as earthquakes or heavy wind loads. By adhering strictly to these guidelines, constructors and architects can guarantee the safety and durability of their projects, gaining trust not only from regulatory bodies but also from clients and occupants. The trend towards sustainable and environmentally friendly construction practices has also seen the rise of mesh made from recycled materials, aligning with green building initiatives. This shift is crucial as the industry seeks innovative ways to reduce carbon footprints without compromising on structural quality or safety. In conclusion, the strategic use of mesh in concrete wall systems exemplifies a confluence of experience, expertise, authoritativeness, and trustworthiness, driving the industry forward. For both new constructions and renovations, the incorporation of mesh stands as a testament to the evolving nature of modern architecture, ensuring that structures remain robust, resilient, and ready to meet the demands of a dynamic world.

Moreover, the process of embedding mesh within concrete is straightforward when done by skilled workers. Precision in this process is essential, as the mesh must be adequately supported and positioned before and during the concrete pour to ensure effective load distribution and structural integrity. Oversight by civil engineers or experienced technicians ensures that the framework is adequately supported until the concrete cures and consolidates the mesh within its matrix. Authoritative construction codes and guidelines underline the necessity of using reinforced mesh to meet or exceed safety standards. These standards ensure that buildings can withstand natural disasters such as earthquakes or heavy wind loads. By adhering strictly to these guidelines, constructors and architects can guarantee the safety and durability of their projects, gaining trust not only from regulatory bodies but also from clients and occupants. The trend towards sustainable and environmentally friendly construction practices has also seen the rise of mesh made from recycled materials, aligning with green building initiatives. This shift is crucial as the industry seeks innovative ways to reduce carbon footprints without compromising on structural quality or safety. In conclusion, the strategic use of mesh in concrete wall systems exemplifies a confluence of experience, expertise, authoritativeness, and trustworthiness, driving the industry forward. For both new constructions and renovations, the incorporation of mesh stands as a testament to the evolving nature of modern architecture, ensuring that structures remain robust, resilient, and ready to meet the demands of a dynamic world.

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.