Feb . 20, 2025 02:16 Back to list

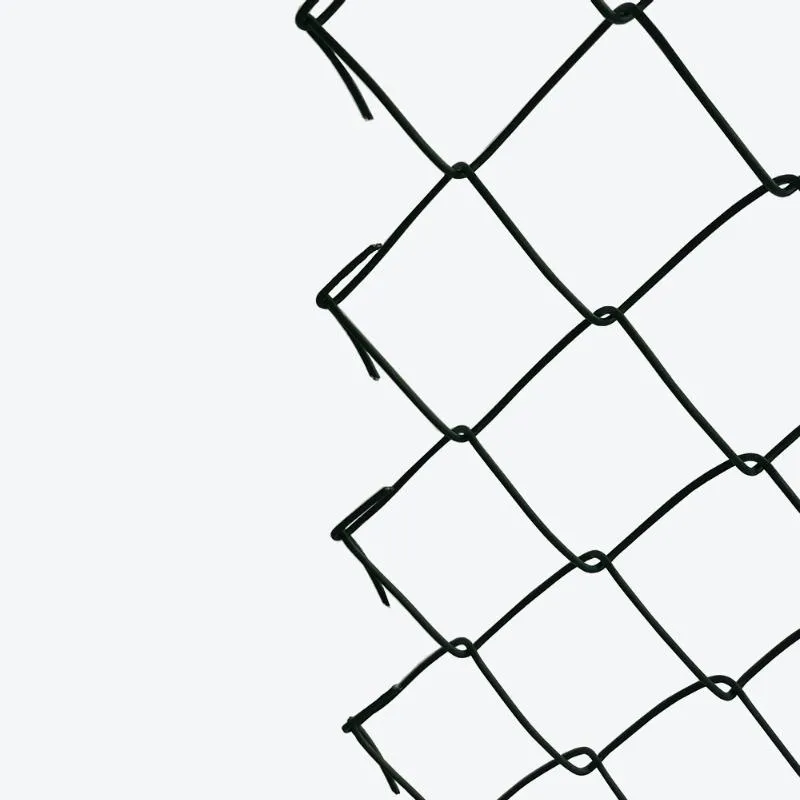

mesh for retaining wall

Mesh for retaining walls plays a crucial role in modern construction, especially in projects where stability and durability are paramount. The application of mesh reinforces retaining walls, providing a significant enhancement in their structural integrity and lifespan. This technology has revolutionized how builders approach earth-retaining projects, offering both economic and environmental benefits.

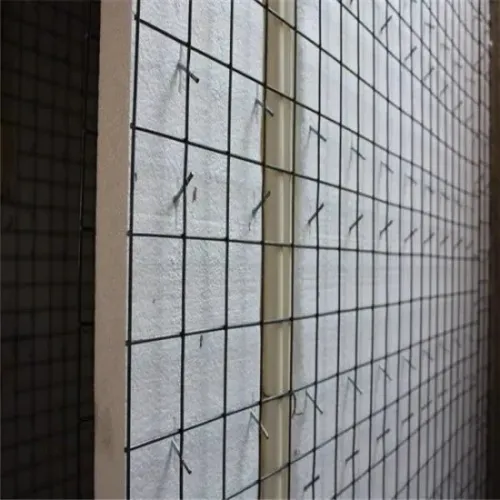

Credibility in construction projects, particularly when employing mesh in retaining walls, hinges on transparency and traceability of materials. Quality assurance is a critical aspect that involves tracking the source of the mesh, verifying its compliance with industry standards, and ensuring it undergoes rigorous testing. Trustworthy suppliers provide certification and documentation to confirm the mesh's structural integrity and environmental compatibility, which builders should review meticulously before proceeding with any project. Sustainability also plays a pivotal role in the discussion of mesh for retaining walls. Innovative mesh materials continue to emerge, focusing on reducing the ecological footprint while maintaining efficiency and strength. For instance, some manufacturers have begun producing geogrids from recycled materials, promoting sustainable practices without compromising on quality. Incorporating such products aligns with global environmental initiatives and enhances the project's overall value by appealing to environmentally conscious stakeholders. Practical experience further indicates that mesh installation impacts the long-term success of a retaining wall. Techniques such as correct anchoring and tensioning of the mesh are crucial to resisting lateral earth pressures effectively. Experienced contractors leverage specialized equipment and follow precise protocols during installation to ensure the mesh functions as intended. In conclusion, the deployment of mesh in retaining walls is an essential practice that combines engineering expertise, authoritative knowledge, and a commitment to sustainable development. Builders and engineers, guided by real-world case studies, academic research, and industry standards, can harness the full potential of mesh technologies to construct retaining walls that are resilient, reliable, and environmentally responsible. As the construction landscape continues to evolve, the integration of innovative materials and best practices will shape the future of retaining wall projects, underscoring the indispensable role of mesh in modern engineering solutions.

Credibility in construction projects, particularly when employing mesh in retaining walls, hinges on transparency and traceability of materials. Quality assurance is a critical aspect that involves tracking the source of the mesh, verifying its compliance with industry standards, and ensuring it undergoes rigorous testing. Trustworthy suppliers provide certification and documentation to confirm the mesh's structural integrity and environmental compatibility, which builders should review meticulously before proceeding with any project. Sustainability also plays a pivotal role in the discussion of mesh for retaining walls. Innovative mesh materials continue to emerge, focusing on reducing the ecological footprint while maintaining efficiency and strength. For instance, some manufacturers have begun producing geogrids from recycled materials, promoting sustainable practices without compromising on quality. Incorporating such products aligns with global environmental initiatives and enhances the project's overall value by appealing to environmentally conscious stakeholders. Practical experience further indicates that mesh installation impacts the long-term success of a retaining wall. Techniques such as correct anchoring and tensioning of the mesh are crucial to resisting lateral earth pressures effectively. Experienced contractors leverage specialized equipment and follow precise protocols during installation to ensure the mesh functions as intended. In conclusion, the deployment of mesh in retaining walls is an essential practice that combines engineering expertise, authoritative knowledge, and a commitment to sustainable development. Builders and engineers, guided by real-world case studies, academic research, and industry standards, can harness the full potential of mesh technologies to construct retaining walls that are resilient, reliable, and environmentally responsible. As the construction landscape continues to evolve, the integration of innovative materials and best practices will shape the future of retaining wall projects, underscoring the indispensable role of mesh in modern engineering solutions.

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.