Dec . 21, 2024 01:55 Back to list

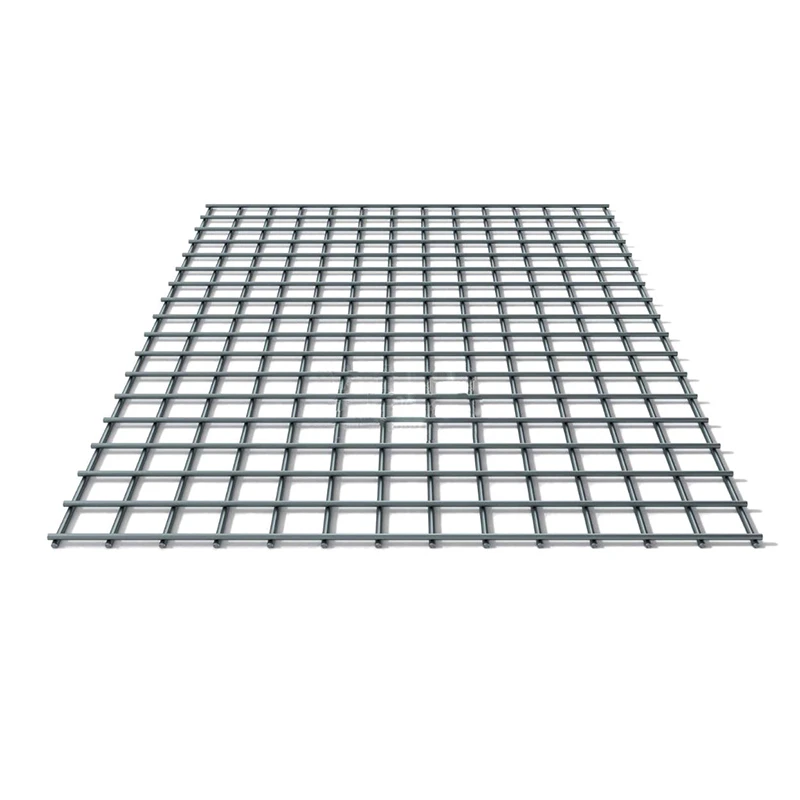

metal grid concrete

The Integration of Metal Grid and Concrete A Revolutionary Approach to Construction

In recent years, the construction industry has been undergoing a transformative shift, thanks in large part to innovative materials and techniques. One of the most exciting advancements is the integration of metal grids within concrete structures. This combination not only enhances the performance and durability of concrete but also opens new avenues for design and sustainability.

Understanding Metal Grid and Concrete

Concrete, a composite material composed of cement, aggregates, and water, has been a staple in construction for centuries. It is recognized for its compressive strength, durability, and resistance to weathering. However, it has its limitations, particularly when it comes to tensile strength and flexibility. On the other hand, metal grids, often made from steel, offer excellent tensile strength and can bear significant loads without deformation. When combined, metal grids and concrete create a composite material that harnesses the strengths of both components.

The use of metal grids in concrete not only provides support but also enhances the structural integrity of buildings. The grid acts as reinforcement, distributing loads more evenly across the concrete surface. This is especially beneficial in designs that must combat lateral forces, such as those experienced during earthquakes or high winds.

Benefits of Metal Grid Concrete

1. Increased Strength and Durability Incorporating metal grids significantly enhances the tensile strength of concrete. This synergy allows structures to withstand greater stress and reduces the likelihood of cracks and failures over time. Consequently, buildings and infrastructure can have a longer lifespan, resulting in cost savings and reduced maintenance needs.

2. Sustainability With growing concerns about sustainability in construction, the combination of metal grids and concrete presents an opportunity to create more eco-friendly buildings. Metal grids can be manufactured from recycled materials, thus reducing the environmental footprint. Additionally, enhanced durability of the composite material can lead to a decrease in resource consumption over the lifespan of a building.

3. Design Flexibility The integration of metal grids allows architects and engineers greater flexibility in their designs. They can create complex shapes and structures that would be difficult or impossible to achieve with traditional concrete alone. This flexibility fosters creativity and innovation in architectural design, pushing the boundaries of what is possible in modern construction.

metal grid concrete

4. Cost-Effectiveness Although the initial investment in metal grids may be higher than conventional reinforcement methods, the long-term cost savings can be substantial. The increased durability and reduced maintenance needs of metal grid concrete mean that structures remain safe and operational longer, ultimately lowering life-cycle costs.

Applications in Modern Construction

The applications of metal grid concrete are diverse and span various sectors, from residential buildings to large-scale infrastructure projects. For instance, bridge constructions have benefited from this technology by achieving longer spans without the need for numerous columns, consequently improving traffic flow and reducing costs. In high-rise buildings, the combination allows for slender column designs, increasing usable floor space without compromising safety.

Moreover, in industrial settings, metal grid-reinforced concrete has been successfully employed in heavy load-bearing floors and foundations, showcasing its ability to perform under extreme conditions. The compatibility of metal grids with other materials, such as fiber-reinforced polymers, also expands the possibilities, creating even more robust systems for various applications.

Challenges and Considerations

Despite its many advantages, the integration of metal grids into concrete also presents challenges. Proper design and execution are crucial to ensure that the load distribution is optimal. Additionally, the corrosion of metal components can be a concern, requiring adequate protection measures. Advances in coatings and treatments are addressing these issues, paving the way for wider acceptance and use of metal grid concrete in the industry.

Conclusion

The fusion of metal grids with concrete represents a significant advancement in construction materials and methods. By enhancing strength, promoting sustainability, and providing design flexibility, this innovative approach is setting new standards in the construction industry. As we move towards a future where efficiency and eco-friendliness dictate best practices, the role of metal grid concrete will undoubtedly become more prominent, offering exciting possibilities for builders and architects around the world.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.