Dec . 04, 2024 17:49 Back to list

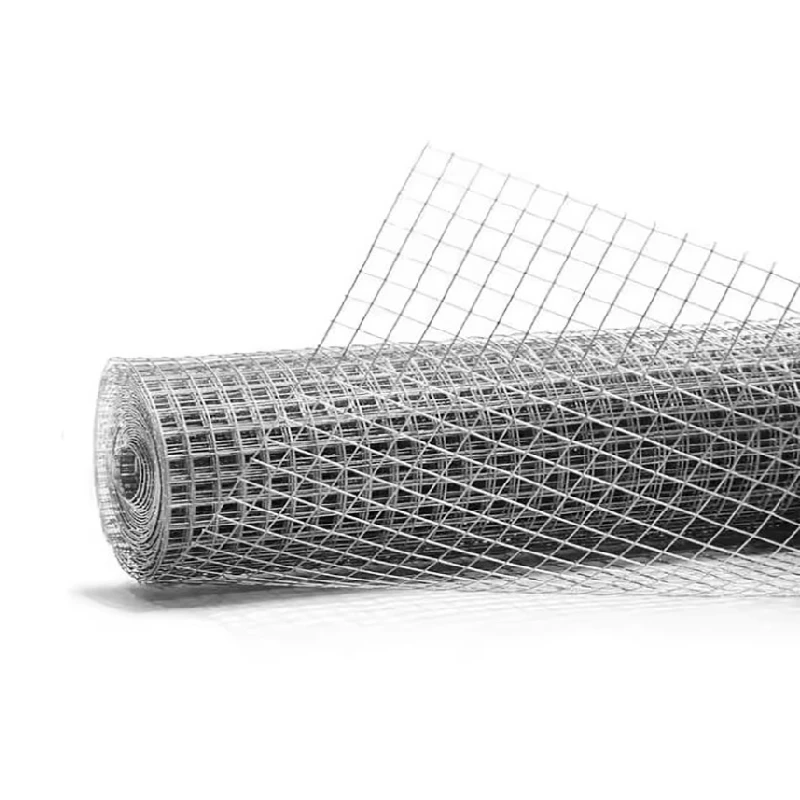

metal mesh concrete

Metal Mesh Concrete Revolutionizing Construction Materials

In the wake of advancements in construction technology, the integration of metal mesh with concrete has emerged as a game-changer in the field of engineering and architecture. Metal mesh concrete combines the durability and versatility of concrete with the tensile strength and flexibility of metal mesh, resulting in a composite material that significantly enhances structural performance. This innovative use of materials not only conserves resources but also provides solutions to some of the industry’s most pressing challenges, such as structural failures, foundation issues, and sustainability.

Understanding Metal Mesh Concrete

Metal mesh concrete refers to the application of metal mesh, typically made from steel or other durable alloys, which is embedded into concrete during the mixture or pouring process. The primary purpose of the metal mesh is to enhance the tensile strength of concrete, which is inherently good in compression but weak in tension. By distributing the load across the structure more evenly, metal mesh helps to prevent cracking and improve overall durability.

Concrete has long been a preferred material in construction due to its compressive strength, versatility, and resistance to fire and decay. However, its susceptibility to cracking under tension can limit its application, especially in structural elements like beams and slabs. The introduction of metal mesh addresses this weakness, allowing for the creation of thin-walled structures that maintain structural integrity under various loads.

Applications of Metal Mesh Concrete

The applications of metal mesh concrete are vast, ranging from residential buildings to large-scale infrastructure projects. In residential construction, metal mesh concrete is often used in floors, walls, and driveways, providing a robust solution that minimizes maintenance costs and prolongs the lifespan of structures. In commercial buildings, it supports large spans that are crucial for open-plan designs.

Moreover, metal mesh concrete is gaining traction in the realm of precast concrete products, where elements can be manufactured off-site and installed on-site efficiently. This method not only accelerates construction timelines but also contributes to waste reduction by optimizing material use.

In infrastructure projects such as bridges and highways, metal mesh concrete offers the strength needed to withstand significant stress from traffic loads while maintaining flexibility against environmental conditions. It is also being utilized in architectural applications, where designers are increasingly drawn to the aesthetic possibilities of combining metal mesh with the raw visuals of concrete.

metal mesh concrete

Benefits of Metal Mesh Concrete

The benefits of metal mesh concrete extend well beyond enhanced structural integrity. One of the primary advantages is increased resistance to cracking and shrinkage. By preventing these common issues, metal mesh reduces the need for repairs and maintenance over time, ultimately leading to lower lifecycle costs for property owners.

Additionally, this composite material has significant implications for sustainability. By allowing for thinner structures, metal mesh concrete can reduce the amount of material required, thereby minimizing the carbon footprint associated with production and transport. Furthermore, the durability of metal mesh concrete translates into structures that last longer, reducing the frequency of replacements and renovations, which consume both time and resources.

Safety is another crucial aspect—structures built using metal mesh concrete can be designed to withstand seismic activity, provide better performance under extreme weather conditions, and offer greater resistance to fire and corrosion. This makes metal mesh concrete a reliable choice for areas prone to such hazards.

Future of Metal Mesh Concrete

As construction technologies continue to evolve, the future of metal mesh concrete looks promising. Research is being conducted to explore new alloys and coatings for metal meshes that can enhance performance and longevity further. Innovations in 3D printing and prefabrication techniques may also lead to more efficient methods of incorporating metal mesh into concrete applications.

Moreover, as sustainability becomes an increasingly important factor in construction, the role of metal mesh concrete will likely expand. Environmental regulations and a growing awareness of climate change will push the industry towards materials that not only perform well but also align with greener construction practices.

In conclusion, metal mesh concrete represents a significant step forward in construction materials, offering enhanced strength, durability, and sustainability. As the industry continues to explore the potential of this composite material, it is poised to transform the way we design and build, creating safer, more efficient, and environmentally friendly structures for the future.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.