Feb . 19, 2025 01:14 Back to list

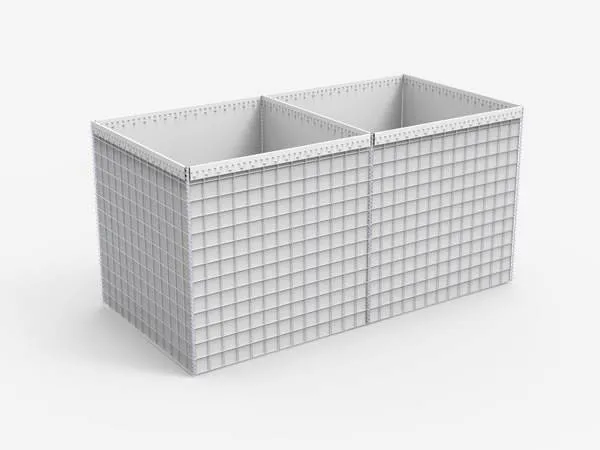

metal mesh for concrete

In the realm of construction, metal mesh for concrete has emerged as an indispensable component, enhancing both the strength and durability of concrete structures. This comprehensive exploration will delve into the multifaceted benefits of metal mesh, shedding light on its crucial role in modern construction.

Field professionals often cite the adaptability of metal mesh as one of its superior attributes. It can be employed in a wide range of concrete applications, from simple residential projects to complex commercial and civil engineering structures. Sidewalks, driveways, walls, and floors are just a few examples of where metal mesh can be utilized to prevent cracking and structural deterioration over time. Experience in the field underscores the critical role that metal mesh plays in seismic zones. Areas prone to earthquakes benefit immensely from the additional tensile strength that the mesh provides. In such regions, the capacity of metal mesh to absorb and distribute seismic energy can be the deciding factor between a structure that remains intact and one that sustains significant damage—or even collapses. Trust in metal mesh for concrete arises from its consistent performance across various applications. Construction experts advocate for its use, particularly when long-term durability and cost-effectiveness are considered top priorities. Meanwhile, regulatory bodies and construction codes frequently highlight the use of metal mesh, underlining its establishment as a standard practice in building construction. Lastly, the environmental impact of using metal mesh should not be underestimated. By extending the longevity of concrete structures, the need for replacements and repairs—which consume additional resources and energy—is dramatically reduced. This aligns with sustainable building practices and addresses the growing global emphasis on reducing construction waste and environmental footprints. In summation, metal mesh for concrete is not merely an optional enhancement but a strategic necessity for modern construction. Its ability to fortify concrete, coupled with ease of installation and economic advantages, render it a staple in the industry. As construction demands evolve, the role of metal mesh is set to become even more prominent, solidifying its status as a fundamental component that harmonizes strength, durability, and sustainability.

Field professionals often cite the adaptability of metal mesh as one of its superior attributes. It can be employed in a wide range of concrete applications, from simple residential projects to complex commercial and civil engineering structures. Sidewalks, driveways, walls, and floors are just a few examples of where metal mesh can be utilized to prevent cracking and structural deterioration over time. Experience in the field underscores the critical role that metal mesh plays in seismic zones. Areas prone to earthquakes benefit immensely from the additional tensile strength that the mesh provides. In such regions, the capacity of metal mesh to absorb and distribute seismic energy can be the deciding factor between a structure that remains intact and one that sustains significant damage—or even collapses. Trust in metal mesh for concrete arises from its consistent performance across various applications. Construction experts advocate for its use, particularly when long-term durability and cost-effectiveness are considered top priorities. Meanwhile, regulatory bodies and construction codes frequently highlight the use of metal mesh, underlining its establishment as a standard practice in building construction. Lastly, the environmental impact of using metal mesh should not be underestimated. By extending the longevity of concrete structures, the need for replacements and repairs—which consume additional resources and energy—is dramatically reduced. This aligns with sustainable building practices and addresses the growing global emphasis on reducing construction waste and environmental footprints. In summation, metal mesh for concrete is not merely an optional enhancement but a strategic necessity for modern construction. Its ability to fortify concrete, coupled with ease of installation and economic advantages, render it a staple in the industry. As construction demands evolve, the role of metal mesh is set to become even more prominent, solidifying its status as a fundamental component that harmonizes strength, durability, and sustainability.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.