Dec . 12, 2024 06:12 Back to list

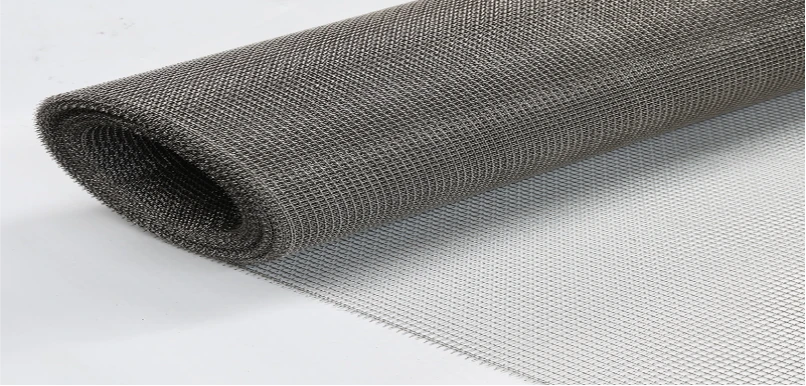

pre crimped wire mesh

Pre-Crimped Wire Mesh An In-Depth Overview

Wire mesh has long been a staple in various industries, offering durability and versatility for countless applications. Among the different types of wire mesh, pre-crimped wire mesh stands out due to its unique characteristics and specific advantages. In this article, we will delve into what pre-crimped wire mesh is, its manufacturing process, applications, and benefits.

What is Pre-Crimped Wire Mesh?

Pre-crimped wire mesh is created by weaving together strands of wire that have been crimped prior to the weaving process. This crimping adds rigidity and stability to the mesh, enhancing its integrity and ensuring that it maintains its shape under various conditions. The crimping process involves introducing waves or bends in the wires, which interlock during the weaving, contributing to the overall strength of the finished product.

Manufacturing Process

The production of pre-crimped wire mesh begins with the selection of high-quality wire. This wire can be made from different materials, including stainless steel, galvanized steel, or other metals, depending on the intended application. Once the appropriate wire is chosen, it undergoes a crimping process where it is subjected to mechanical pressure to form distinct waves.

After crimping, the wires are woven together using specialized machinery. The weaving can be done in various patterns, such as plain, dutch, or twilled, depending on the required specifications. The combination of crimped wires and the chosen weaving pattern leads to a strong, stable mesh that can handle different strain levels and environmental factors.

Applications of Pre-Crimped Wire Mesh

Pre-crimped wire mesh has an extensive range of applications across various sectors. Some of these include

1. Construction and Architecture It is frequently used for reinforcing concrete, providing structural support while allowing for ease of movement and expansion.

2. Filtration In industries such as pharmaceuticals, food processing, and mining, pre-crimped wire mesh is employed as screens for separating materials or filtering liquids and gases. Its durability ensures it can handle high pressures and flows.

3. Automotive This type of wire mesh is used in various parts of vehicles for applications such as exhaust systems, where it helps to direct airflow, reduce noise, and filter particulates.

pre crimped wire mesh

4. Agriculture Farmers utilize pre-crimped wire mesh for fencing, animal enclosures, and for creating trellises. Its strength and resistance to corrosion make it an ideal choice for outdoor use.

5. Security The mesh is also widely used in the security sector, for applications ranging from window guards to fencing in high-security areas.

Benefits of Pre-Crimped Wire Mesh

The advantages of pre-crimped wire mesh are numerous and make it a preferred choice for many applications

- Enhanced Strength and Durability The crimping process increases the mesh's overall strength, making it less prone to bending or breaking under pressure.

- Consistent Performance Due to the uniform crimping of the wires, pre-crimped wire mesh provides consistent performance in various environments, offering reliable results whether used indoors or outdoors.

- Corrosion Resistance Many pre-crimped wire meshes are coated or made from stainless steel, allowing them to resist rust and degradation over time, even in harsh conditions.

- Customizability Manufacturers can produce pre-crimped wire mesh according to specific requirements in terms of size, wire gauge, and crimping style, making it tailor-fit for particular needs.

- Aesthetic Appeal In architectural applications, pre-crimped wire mesh can enhance the visual appeal while providing functionality, adding a modern touch to designs.

Conclusion

In summary, pre-crimped wire mesh is a versatile material that combines strength, durability, and customization. Its wide-ranging applications across different industries highlight its significance in modern manufacturing and construction processes. As industries continue to evolve, the demand for reliable and robust materials like pre-crimped wire mesh is likely to increase, showcasing its enduring value in the global market. Whether for structural reinforcement, filtration, or security purposes, the benefits of pre-crimped wire mesh make it an essential component in many fields.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.