Mar . 07, 2025 06:14 Back to list

Razor Wire

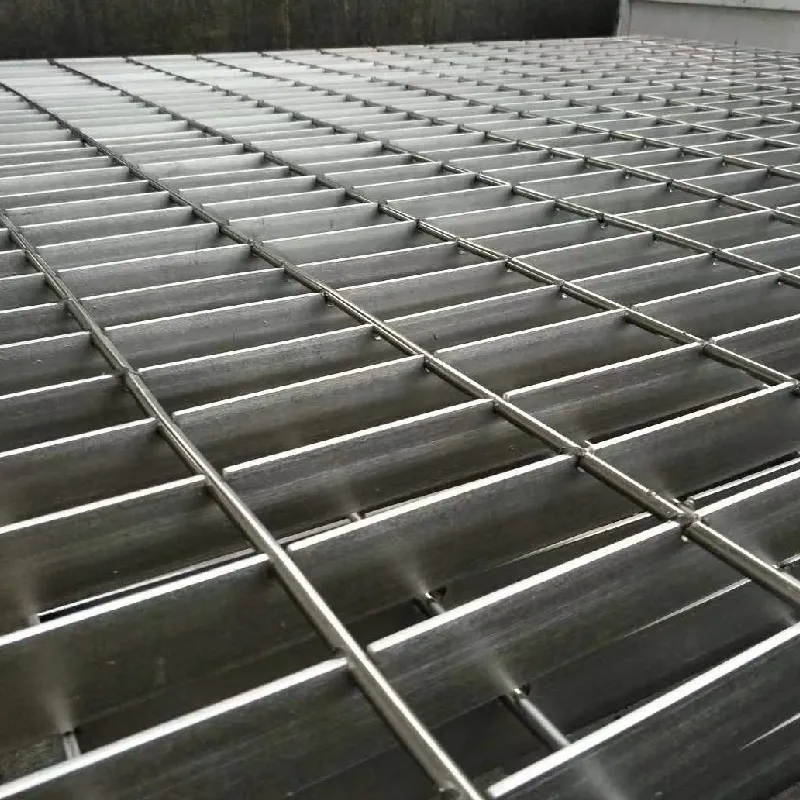

Integrating rebar and wire mesh into concrete slabs is pivotal for enhancing structural integrity and durability in modern construction. This article delves into the essential aspects of using these reinforcement materials, drawing upon real-world expertise and authoritative insights to provide a comprehensive understanding of their application in slab construction.

Expert craftsmen often highlight the importance of proper spacing and tying of rebar to prevent shifting during concrete pouring. Common practices include supporting rebar on cement bricks or using plastic rebar chairs to maintain its position during the pour. In contrast, wire mesh is typically placed in the upper half of the slab thickness to provide early resistance against potential cracking due to settling and curing. Authoritative guidelines often underscore the significance of design considerations and adherence to engineering plans that specify the grade, spacing, and type of reinforcement. This precision ensures that the strengths of both rebar and wire mesh are fully optimized for the intended structural role. In the construction industry, trustworthiness is earned by consistently following these protocols, ensuring that the reinforcement neither becomes an uneconomical overdesign nor a sparing, inadequately supported undertaking. When integrated effectively, rebar and wire mesh work harmoniously, each covering the limitations of the other. Rebar prepares slabs to take on heavy, dynamic loads while wire mesh provides a flexible reinforcement that can accommodate minor stresses and environmental variations. In slabs, these components are critical in maintaining structural coherence over long periods, exhibiting superior resistance to environmental damages compared to non-reinforced concrete. Finally, the successful use of rebar and wire mesh requires professional expertise combined with real-world experience. Adhering to industry best practices, authenticated by scientific research and proven by time, can secure the trust of engineers, architects, and clients alike, establishing a foundation not just of concrete, but of lifelong reliability and architectural integrity.

Expert craftsmen often highlight the importance of proper spacing and tying of rebar to prevent shifting during concrete pouring. Common practices include supporting rebar on cement bricks or using plastic rebar chairs to maintain its position during the pour. In contrast, wire mesh is typically placed in the upper half of the slab thickness to provide early resistance against potential cracking due to settling and curing. Authoritative guidelines often underscore the significance of design considerations and adherence to engineering plans that specify the grade, spacing, and type of reinforcement. This precision ensures that the strengths of both rebar and wire mesh are fully optimized for the intended structural role. In the construction industry, trustworthiness is earned by consistently following these protocols, ensuring that the reinforcement neither becomes an uneconomical overdesign nor a sparing, inadequately supported undertaking. When integrated effectively, rebar and wire mesh work harmoniously, each covering the limitations of the other. Rebar prepares slabs to take on heavy, dynamic loads while wire mesh provides a flexible reinforcement that can accommodate minor stresses and environmental variations. In slabs, these components are critical in maintaining structural coherence over long periods, exhibiting superior resistance to environmental damages compared to non-reinforced concrete. Finally, the successful use of rebar and wire mesh requires professional expertise combined with real-world experience. Adhering to industry best practices, authenticated by scientific research and proven by time, can secure the trust of engineers, architects, and clients alike, establishing a foundation not just of concrete, but of lifelong reliability and architectural integrity.

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.